Method for detecting welding firmness of lithium ion battery tab

A lithium-ion battery and tab welding technology, applied in the direction of material resistance, can solve the problems that cannot guarantee the objectivity and scientificity of the pulling force value, hidden dangers of lithium battery quality, unfavorable inspection and analysis, etc., and achieve the effect of improving the control rate of defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

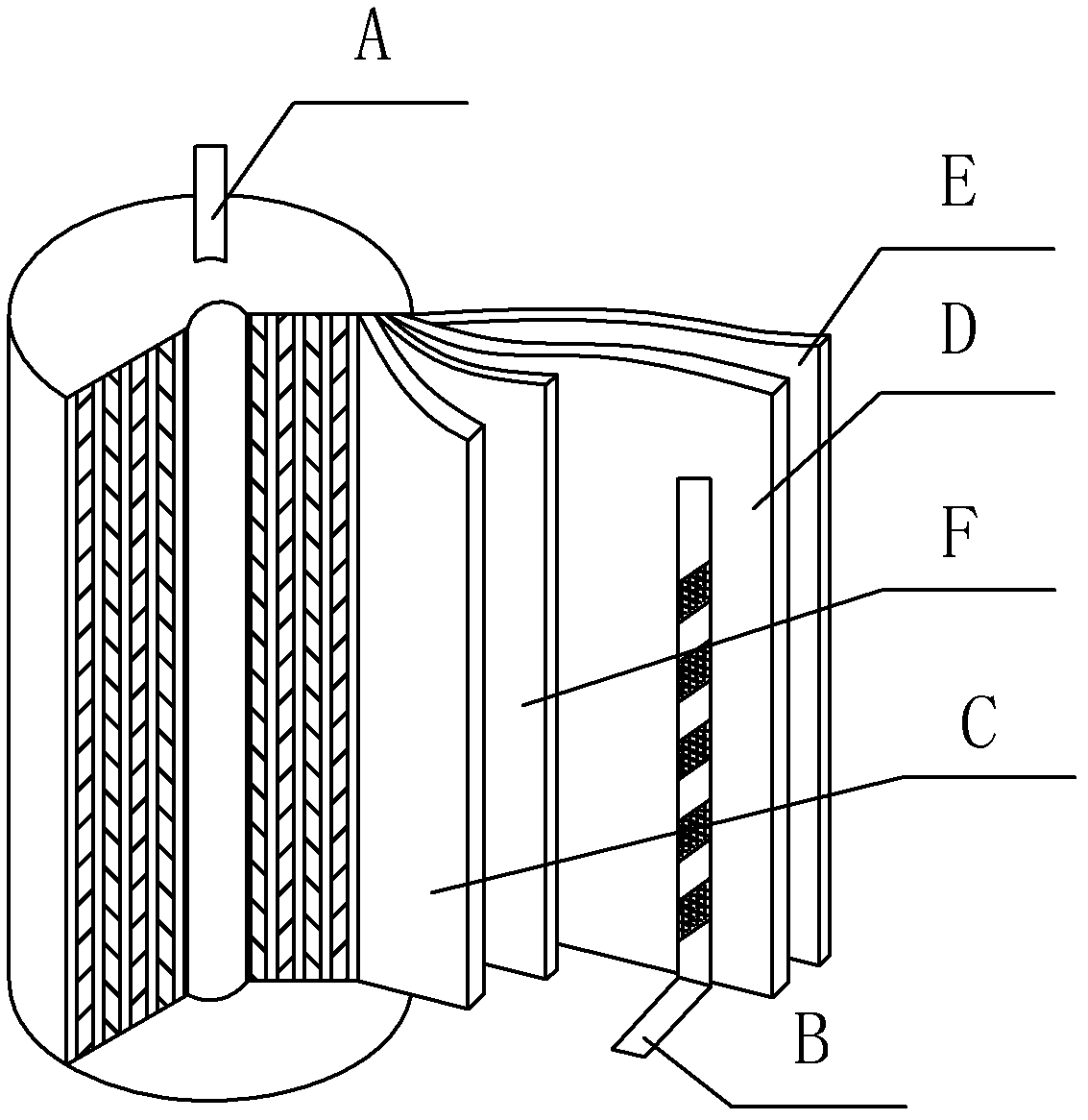

[0027] The working principle of the tab welding machine is: use high-frequency vibration waves to transmit to two metal surfaces to be welded, and under pressure, make the two metal surfaces rub against each other to form fusion between molecular layers. And the point where each substrate sheet and the ear strap are fused has its own impedance. And the impedance distribution of each fusion point after welding is relatively consistent: generally, the welding impedance of the positive and negative base materials and the positive and negative ear straps is 3±0.15mΩ.

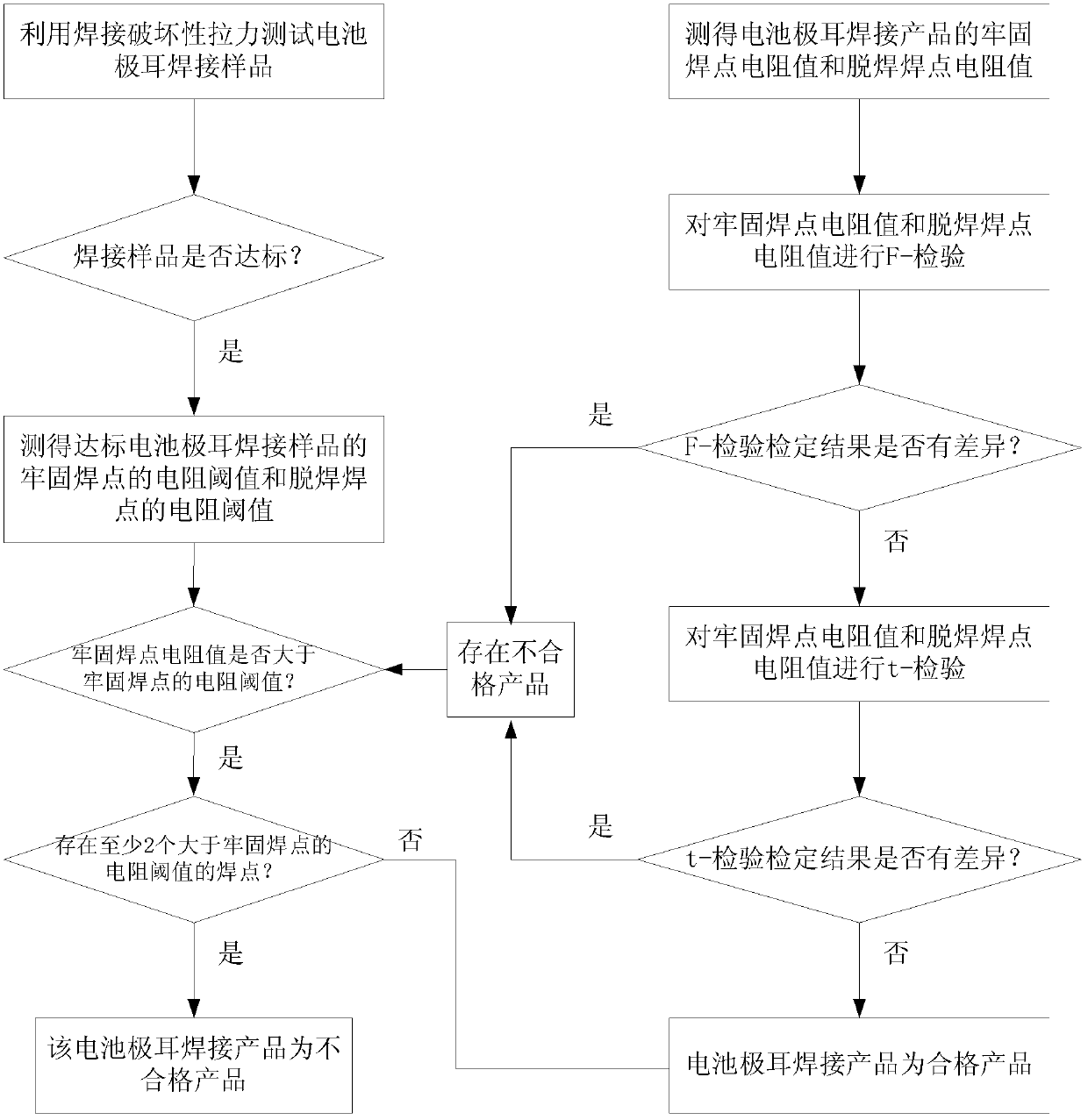

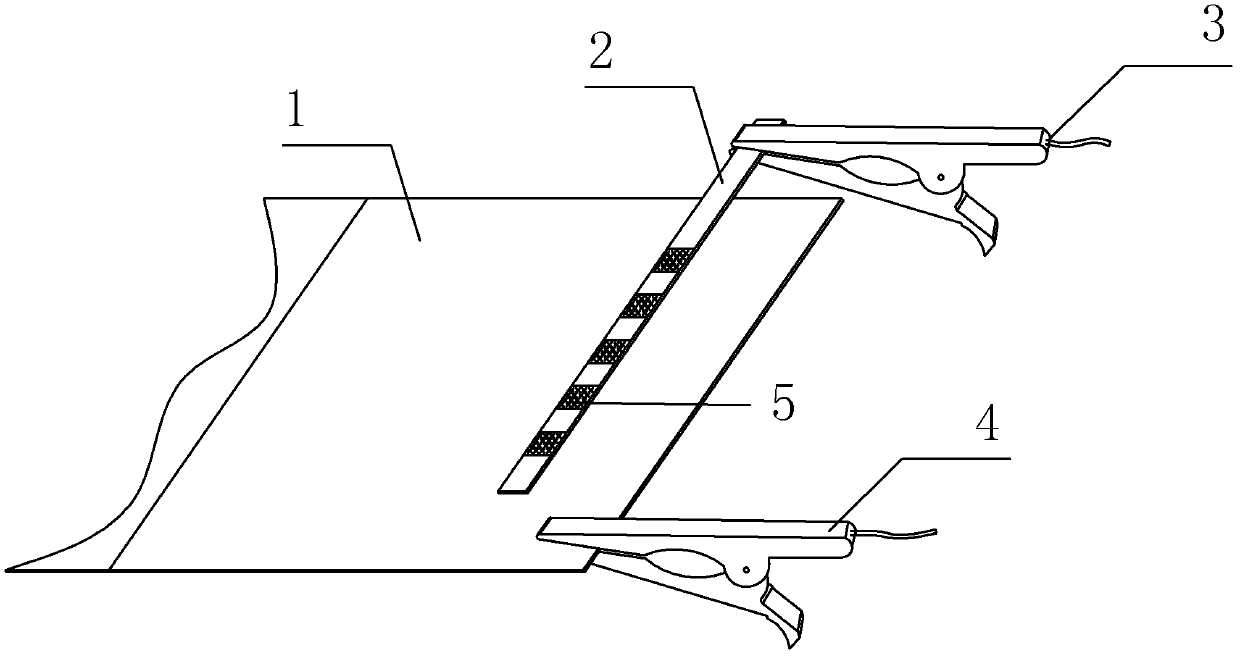

[0028] This embodiment provides a method for detecting the welding firmness of the tabs of lithium-ion batteries. The method uses a DC internal resistance meter to test the impedance of the fusion point of the substrate sheet and the tab strap, and according to the reference experience value of the fusion point of the positive and negative electrodes Do delete selection, if the value is within the reference value ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com