Modifiable tracking control method for images of hot-rolled plate blanks

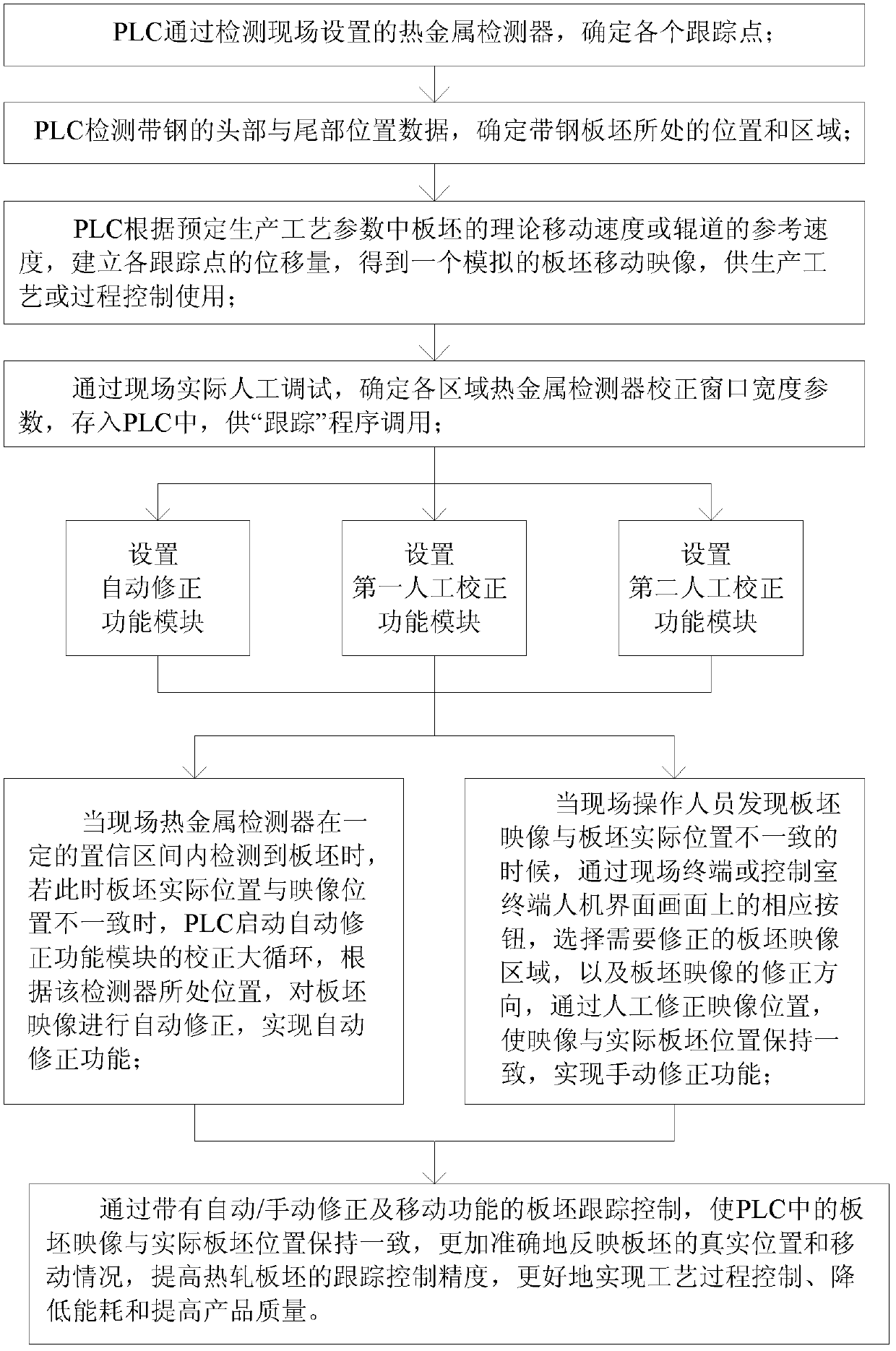

A tracking control and slab technology, applied in rolling mill control devices, metal rolling, metal rolling, etc., can solve problems such as equipment damage, difficulty, inability to correct or adjust in time, and achieve process control and improve tracking control. Accuracy, the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

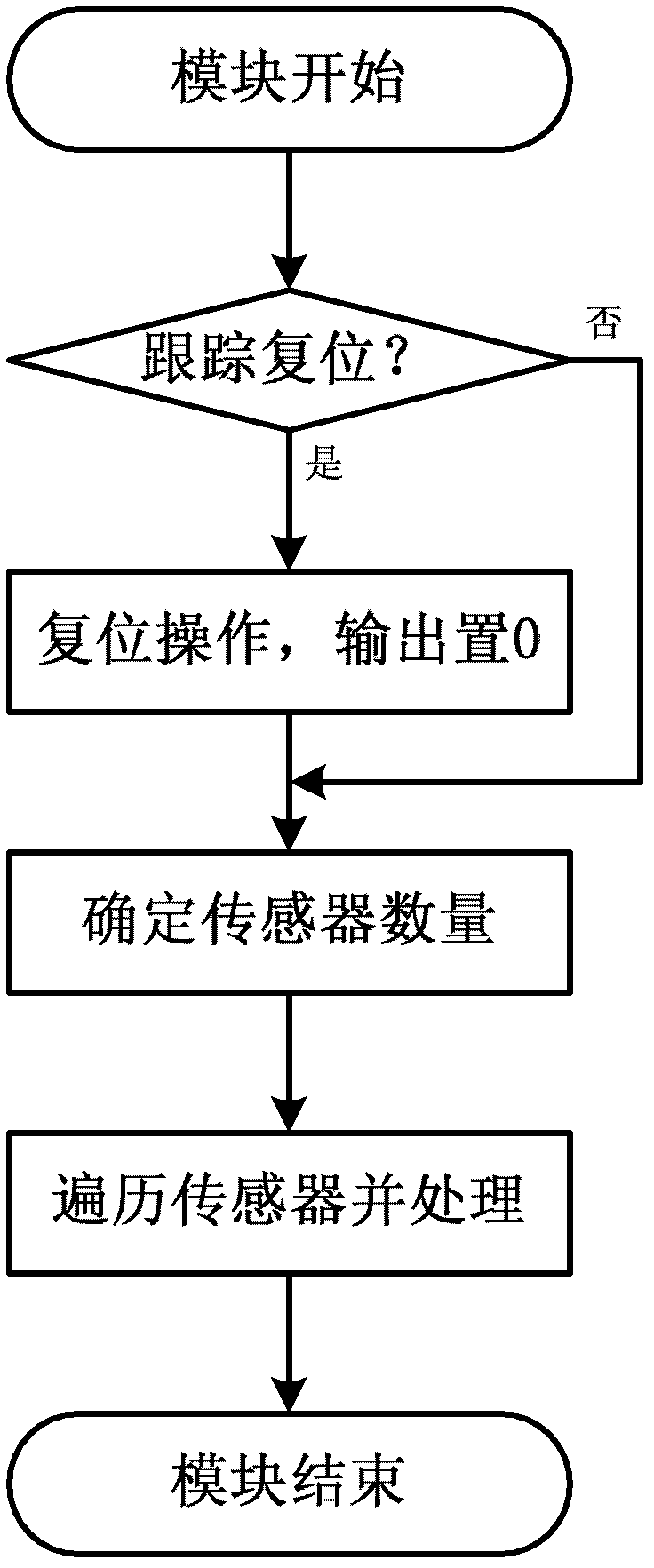

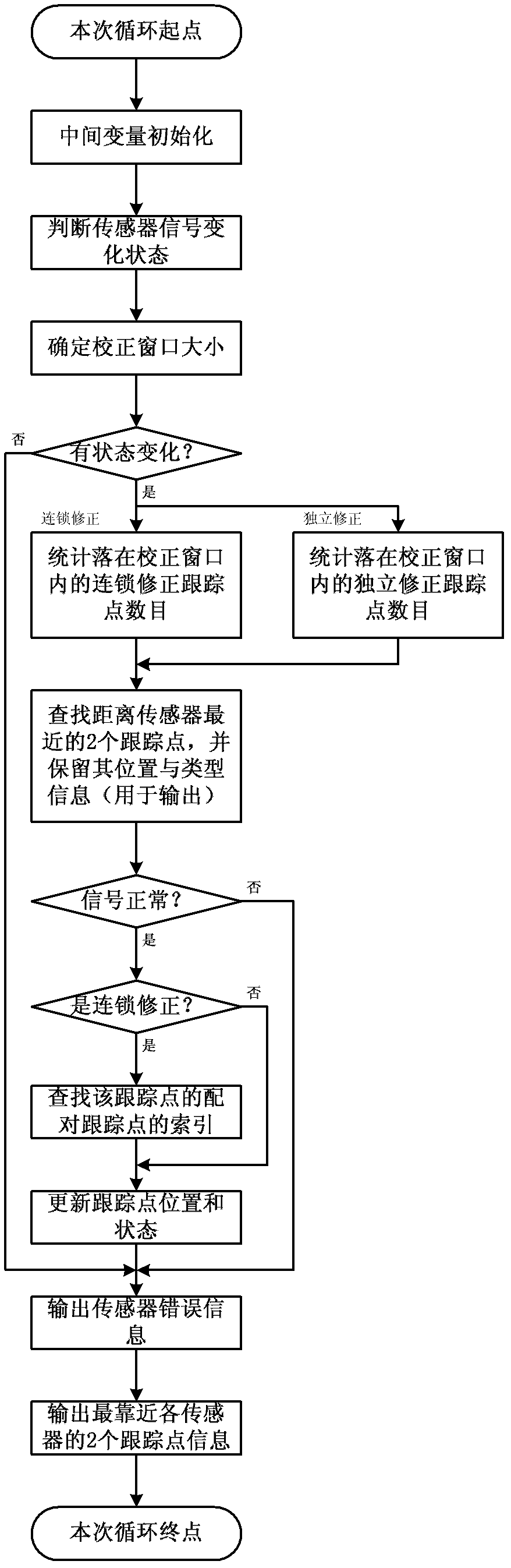

Method used

Image

Examples

Embodiment

[0176] This technical solution has been debugged and tested in the 1880 rough rolling area of the applicant company. After debugging, the window parameters of the hot metal detector in the rough rolling area are as follows:

[0177] sensor

Signal rising edge window width (m)

Signal falling edge window width (m)

HMD3001

2.000

2.000

HMD3002

2.000

2.000

HMD3003

1.030

1.030

HMD3004

0.925

1.925

HMD3006

2.000

2.000

HMD3101

2.000

2.000

HMD3102

2.000

2.000

HMD3103

2.000

2.000

HMD3104

2.000

2.000

HMD3105

2.000

2.000

HMD3201

2.000

2.000

HMD3202

2.000

2.000

HMD3203

2.000

2.000

HMD3204

2.000

2.000

HMD3205

2.000

2.000

HMD3206

2.000

2.000

HMD3208

2.000

2.000...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com