Grinder

A pulverizer and casing technology, applied in the field of pulverizing coal gangue and shale, can solve the problems of difficult to ensure uniform pulverization, easy wear of the hammer head, affecting the quality of raw materials, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

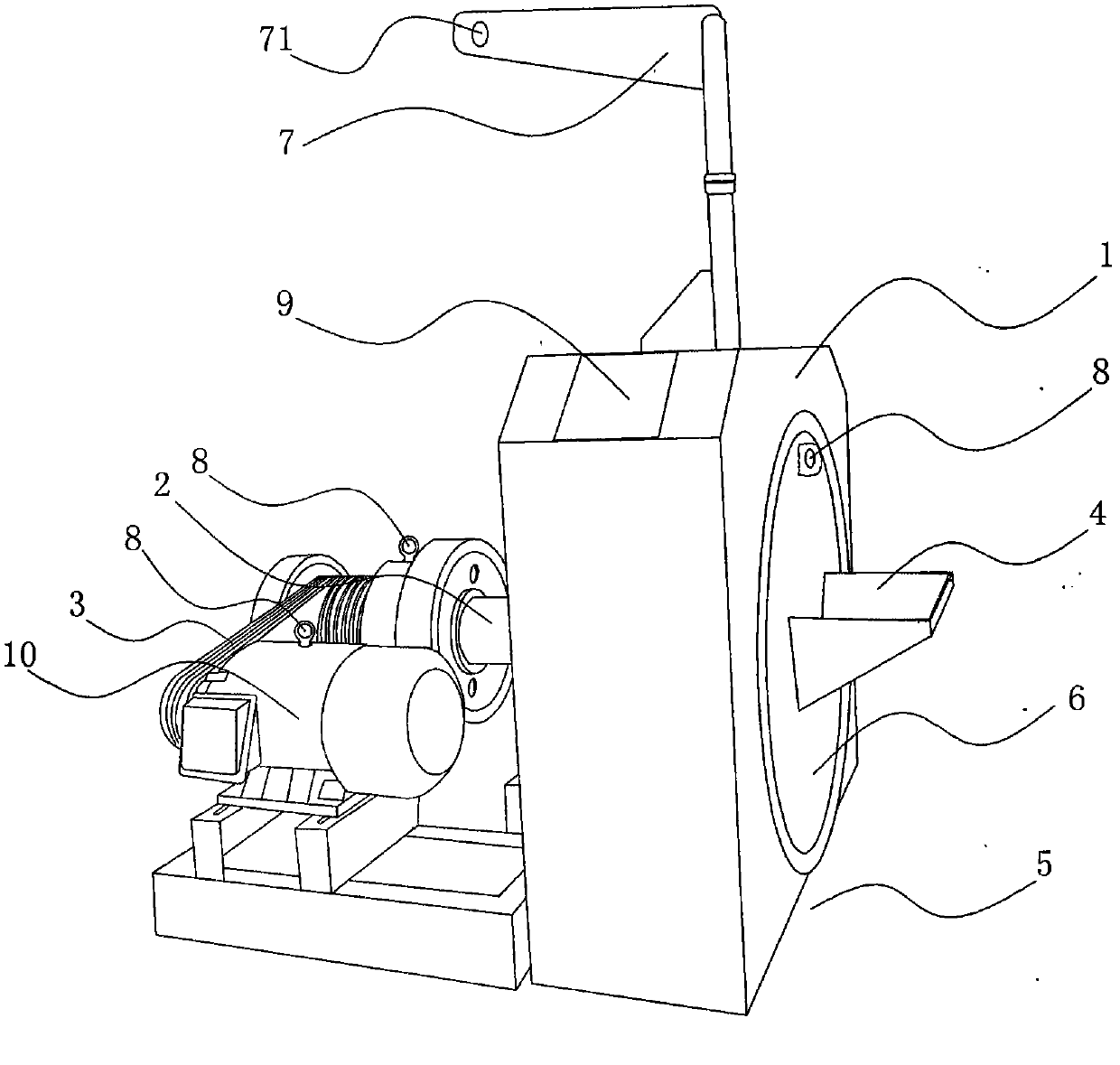

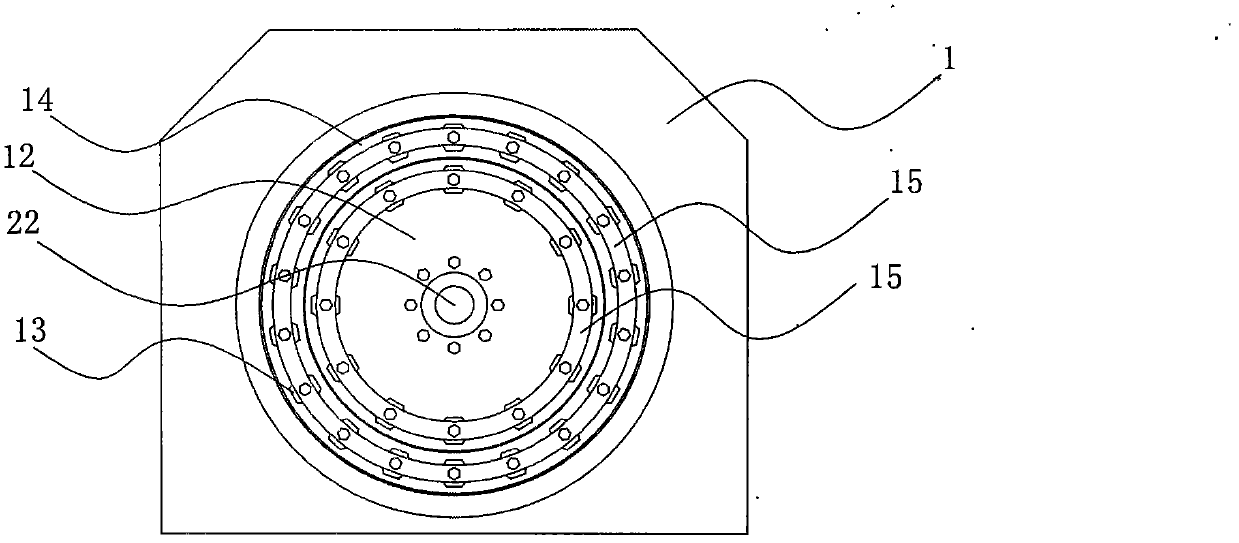

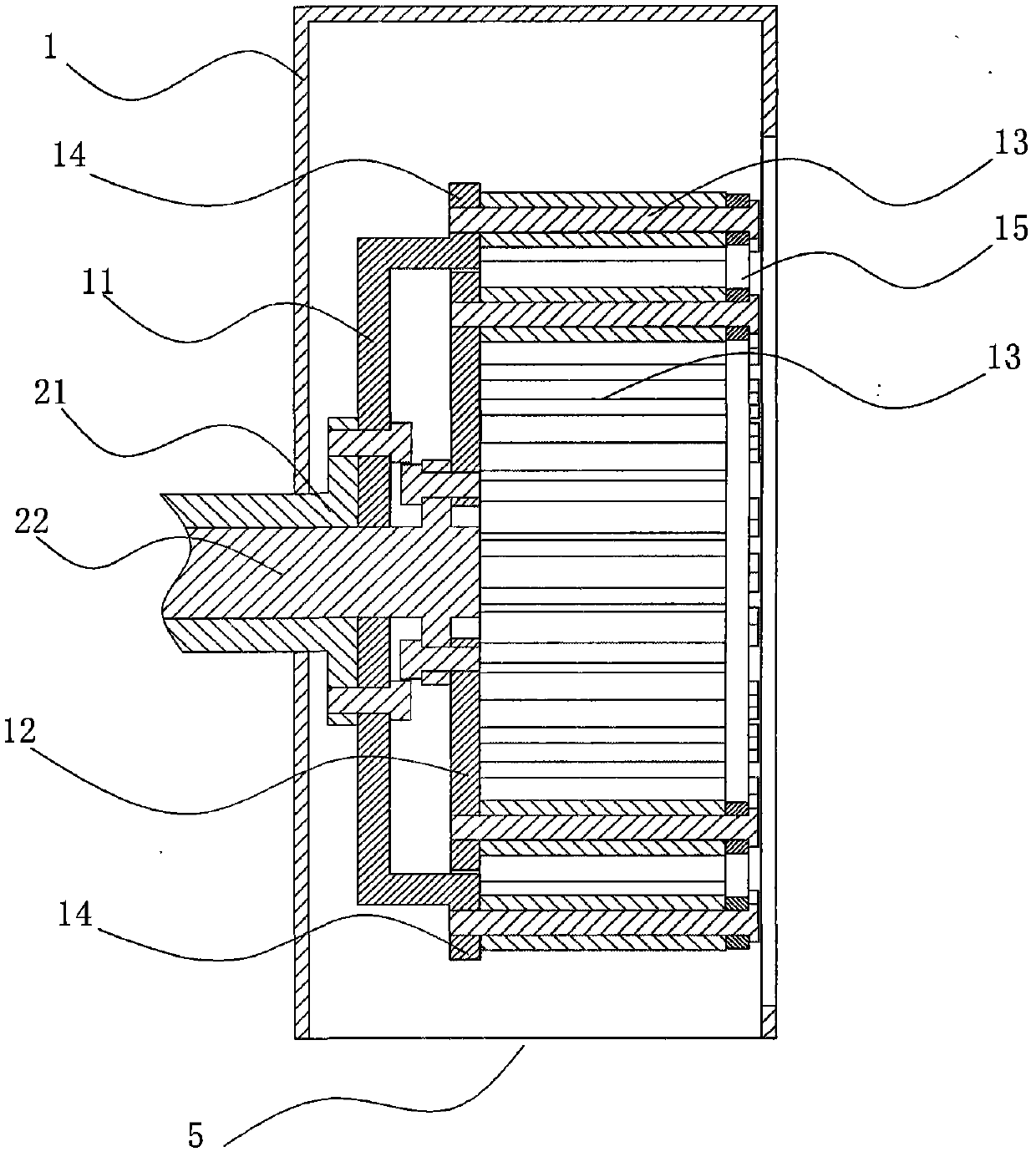

[0025] see Figure 1-3 , a pulverizer, comprising a casing 1 and a rotating shaft 2, the rotating shaft 2 extends into the casing 1, the rotating shaft 2 is connected to a motor 10 through a crawler belt 3, a detachable round cover 6 is arranged on the side wall of the casing 1, The middle part of the round cover 6 is provided with a feed inlet 4, and the bottom of the casing 1 is opened to form a discharge outlet 5, and the casing 1 is provided with a turntable I11 and a turntable II12. There are two rotating shafts 2, namely the concentric rotating shaft I21 and the rotating shaft II22. The rotating shaft I21 is hollow, and the rotating shaft II22 passes through the rotating shaft I21 and is exposed at both ends. The turntable I11 and the turntable II12 are respectively connected to the rotating shaft I21 and the rotating shaft II22, and a plurality of rolls 13 are arranged at the edges of the turntable I11 and the turntable II12. The rolls 13 on the turntable I11 and the t...

Embodiment 2

[0031] see Figure 4 and Figure 5 , the rotating shaft I21 and the rotating shaft II22 are arranged on both sides of the casing 1, and the diameter of the rotating disk II12 is smaller than that of the rotating disk I11. Compared with the overlapping design of double rotating shafts in embodiment 1, the two rotating shafts in this embodiment adopt a symmetrical structure, which can save space, while the symmetrical distribution of double rotating shafts has a relatively simple structure and is easy to maintain. Other parts of this embodiment are the same as in Embodiment 1, and the working principle is also the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com