Powder preparation with diatomite as carrier and application method

A diatomaceous earth and carrier technology, applied in the field of pesticides, can solve the problems of poor spraying effect, chemical adhesion, and poor suspension effect, and achieve excellent leaf adhesion, fineness, and compensation for uneven adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

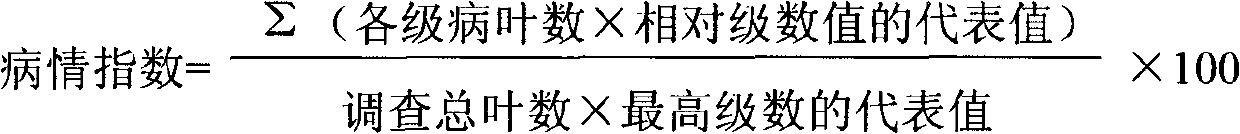

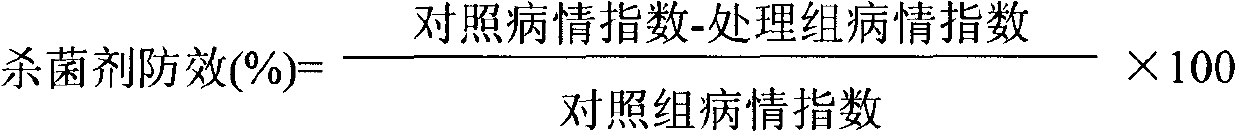

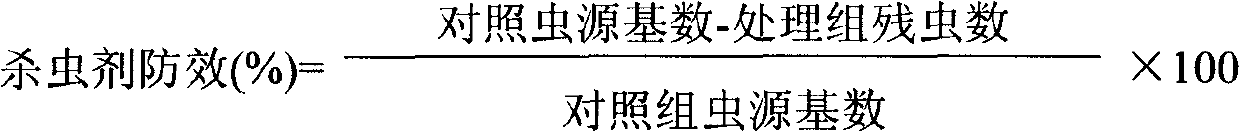

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: 5% dimethomorph dust agent, wherein the former medicine of dimethomorph accounts for 5% of gross weight, wetting agent sodium lauryl sulfate accounts for 2% of gross weight, dispersant sodium lignosulfonate It accounts for 5% of the total weight, diatomite accounts for 78% of the total weight, and white carbon black accounts for 10% of the total weight. After mixing, pulverization by jet mill and secondary mixing, the fineness of dust agent reaches D90=14.12, D50=9.28, D10=3.53.

Embodiment 2

[0034] Embodiment 2: 5% sclerotia net dust agent, wherein the former medicine of sclerotia accounts for 5% of gross weight, and wetting agent sodium butylnaphthalene sulfonate accounts for 2% of gross weight, and dispersant NNO accounts for 5% of gross weight , Diatomaceous earth accounts for 78% of the total weight, white carbon black accounts for 5% of the total weight, and talc accounts for 5% of the total weight. After mixing, crushing by jet mill and secondary mixing, the fineness of the dust agent reaches D90=15.01, D50=9.34, D10=3.54.

Embodiment 3

[0035] Embodiment 3: 2% difenoconazole dust agent, wherein the original drug of difenoconazole accounts for 2% of the total weight, the wetting agent lauryl polyoxyethylene ether accounts for 2% of the total weight, silicon Algae earth accounts for 80% of the total weight, white carbon black accounts for 5% of the total weight, and clay accounts for 11% of the total weight. After mixing, crushing by jet mill and secondary mixing, the fineness of the dust agent reaches D90=14.44, D50=9.23, D10=3.56.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com