Corrosion-resistant heat sink and corrosion-resistant heat sink

A heating element and corrosion-resistant technology, which is applied in the fields of corrosion-resistant heat sinks and corrosion-resistant heating elements, can solve the problems of difficult processing, short life of heat concentration, poor thermal shock resistance, etc. Effect of improving performance and thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

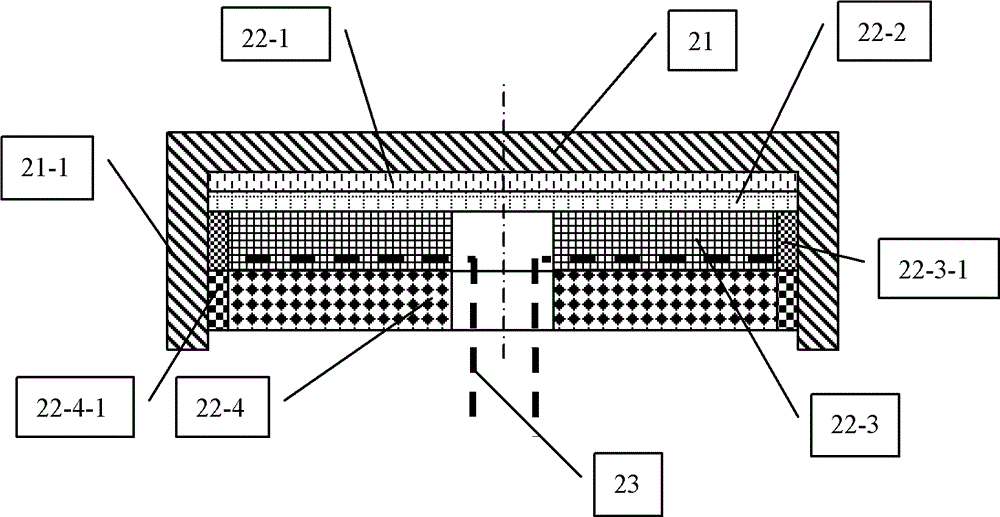

[0051] Refer to attached figure 1 . Provided in this embodiment is a disc-shaped corrosion-resistant heating sheet, which includes an austenite-ferrite stainless steel plate 21, which is sintered with 4 layers of glass-ceramic substrates on the austenite-ferrite stainless steel plate 21. Layered glass-ceramic-based multiphase composite ceramics composed of phase composite ceramics 22-1, 22-2, 22-3, and 22-4, that is, combined into axial layers, and the layered glass-ceramic-based multiphase composite ceramics belt There are frames 22-3-1 and 22-4-1, the frame 22-3-1 is located on the periphery of the glass ceramic matrix multiphase composite ceramic layer 22-3, and the frame 22-4-1 is located on the glass ceramic matrix multiphase composite ceramic layer On the periphery of layer 22-4, the austenitic·ferritic stainless steel plate 21 has a flanging 21-1, and the flanging 21-1 constitutes the outermost frame, so as to be compatible with the frame 22-3-1, 22- 4-1 is combined i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com