Connection structure

A bonding structure and bonding pad technology, applied in the direction of connection, fixed connection, conductive adhesive connection, etc., can solve the problems of short circuit, short circuit of bonding pad, easy to be squeezed to the surrounding area, etc., to reduce accumulation, improve process, avoid The effect of the short circuit phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

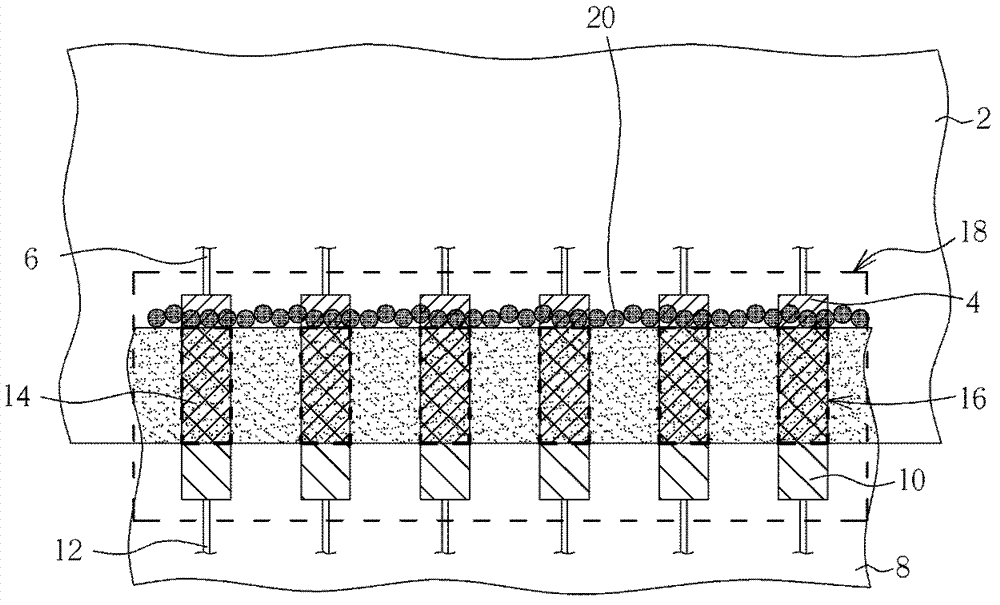

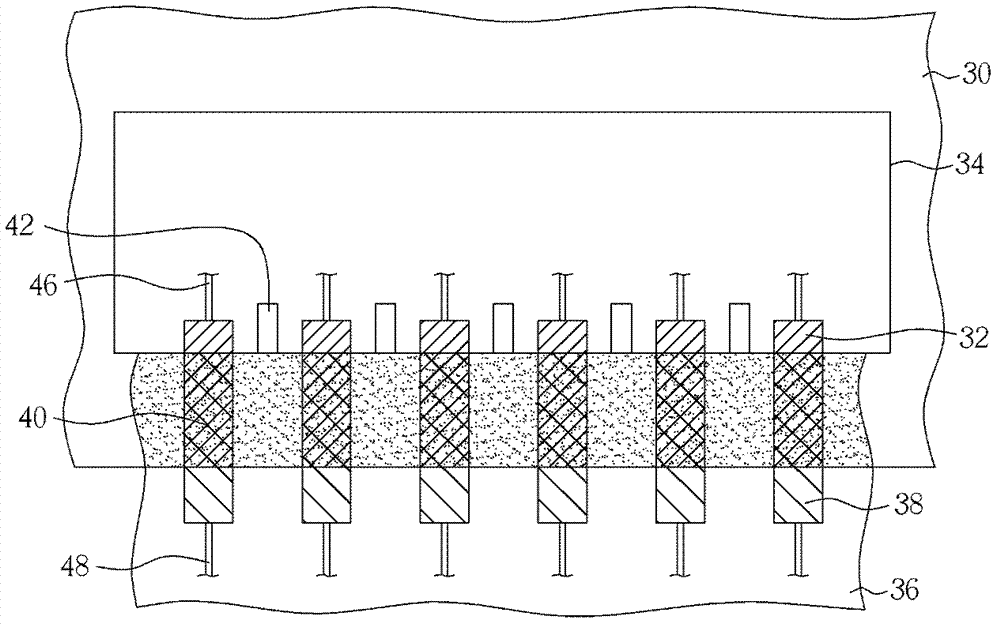

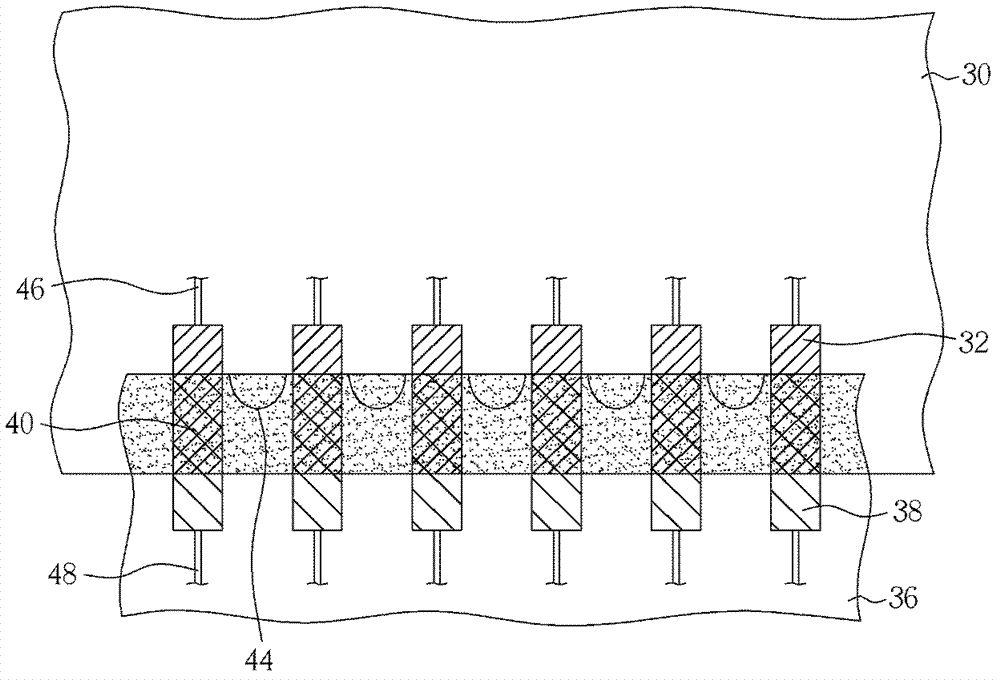

[0029] Figure 2 to Figure 9 It is several specific embodiments according to the present invention. For the convenience of reading, except for Figures 5 and 8, each figure is drawn in a manner that each component is assumed to be transparent, but those skilled in the art should know the relative positions of each component after understanding the present invention. And it should be noted that each element is not drawn according to the actual size ratio.

[0030] figure 2 It is a schematic plan view of a bonding structure according to the first embodiment of the present invention. In this bonding structure, a plurality of first bonding pads 32 are located on a first substrate 30 , and the protective layer 34 partially covers each of the first bonding pads 32 . The second substrate 36 and the first substrate 30 are arranged to face...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com