Crankcase ventilation system of supercharged gasoline engine and work method of crankcase ventilation system

A technology for crankcase ventilation and gasoline engine, which is applied to crankcase ventilation, engine components, machines/engines, etc., can solve the problems of high heat load, high oil temperature, and large negative value of internal bending pressure of the supercharged gasoline engine, etc. Achieve increased operational reliability, improved exhaust emissions, optimized crankcase ventilation systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

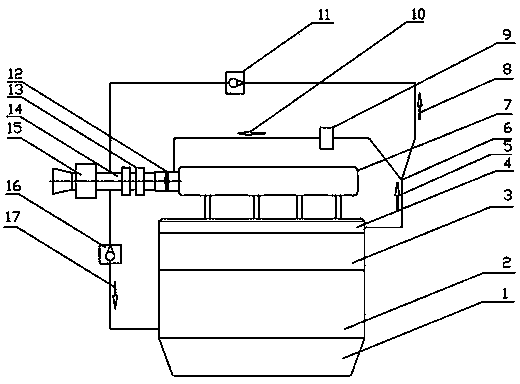

[0021] Combine below figure 1 , the present invention is further described:

[0022] A crankcase ventilation system for a supercharged gasoline engine, the direction of crankcase exhaust gas at low load: valve chamber cover 4→tee pipe 6→PCV valve 9→intake manifold 7→combustion chamber, air filter 15 and An air supply channel 17 is added between the intake hose 14 between the superchargers 13 and the crankcase, and a check valve 16 for the air supply channel is provided on the air supply channel 17 to supply fresh air to: the intake hose 14 →Air supply channel 16→Air supply channel check valve 16→Crankcase→Cylinder block 2→Valve chamber cover 4, the waste gas generated follows the trend of the crankcase exhaust gas during the low load. Crankcase exhaust gas direction under high load: valve chamber cover 4→tee pipe 6→exhaust gas passage check valve 11→intake hose 14→supercharger 13→throttle valve body 12→intake manifold 7 → Combustion chamber.

[0023] When the exhaust gas of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com