Method for performing in situ treatment on acid mine water by using crop seed husks

A technology of in-situ treatment and crops, which is applied in mining equipment, mining equipment, earth drilling and mining, etc., can solve the problems of polluting groundwater, high cost, and poor practicability, and achieves a product that is not easy to decompose, low in use cost, and low in price. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

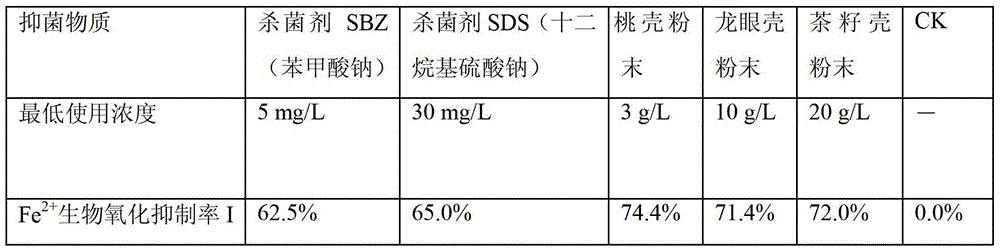

[0058] A method for in-situ treatment of acidic water in mines using crop seed husks, comprising the steps of:

[0059] (1) Detect the crack surface or acid generation point where acidic water seeps out of the mine;

[0060] (2) Preparation of bioinhibitor: cut and grind the longan shell into a powder with a particle size of 80 mesh, then add 20g / L of white latex special modified starch and water to prepare a bioinhibitor with a pH value of 7 agent; wherein the mass volume ratio of longan shells in the biological inhibitor is 10g / L;

[0061] (3) On the crack surface or the acidic water surface at the acid production point, use the biological inhibitor in (2) to spray or brush the inhibitor layer with a thickness of 3 mm, repeat twice, and the inhibitor layer will fully cover the crack Noodles or acid-generating points are suitable;

[0062] (4) Preparation of alkaline flocculation mixture: 10% Na(OH) solution and anionic polyacrylamide are mixed evenly at a volume ratio of 1...

Embodiment 2

[0065] A method for in-situ treatment of acidic water in mines using crop seed husks, comprising the steps of:

[0066] (1) Detect the crack surface or acid generation point where acidic water seeps out of the mine;

[0067] (2) Preparation of bioinhibitor: cut and grind walnut shells into a powder with a particle size of 200 mesh, then add 30g / L of white latex special modified starch and water to prepare a bioinhibitor with a pH value of 7.5 agent; the mass volume ratio of walnut shells in the biological inhibitor is 3g / L;

[0068] (3) On the crack surface or the acidic water surface at the acid production point, use the biological inhibitor in (2) to spray or brush the inhibitor layer with a thickness of 4mm, repeat three times, and the inhibitor layer will fully cover the crack Noodles or acid-generating points are suitable;

[0069] (4) Preparation of alkaline flocculation mixture: use 10% Na(OH) solution and anionic polyacrylamide to mix evenly according to the volume r...

Embodiment 3

[0072] A method for in-situ treatment of acidic water in mines using crop seed husks, comprising the steps of:

[0073] (1) Detect the crack surface or acid generation point where acidic water seeps out of the mine;

[0074] (2) Preparation of bio-inhibitors: Tea seed shells were cut and ground into powders with a particle size of 60 mesh, and then 50 g / L of white latex-specific modified starch and water were added to prepare bio-inhibitors with a pH value of 8. Inhibitor; the mass-to-volume ratio of the tea seed husk in the biological inhibitor is 3g / L;

[0075] (3) On the surface of the acidic water at the crack surface or acid production point, use the biological inhibitor in (2) to spray or brush a layer of inhibitor layer with a thickness of 5 mm. The inhibitor layer can fully cover the crack surface or acid production point. point is appropriate;

[0076] (4) Preparation of alkaline flocculation mixture: mix 10% Na(OH) solution and anionic polyacrylamide according to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com