Spinning take-up device and spinning take-up equipment

A technology of coiling device and spinning device, which is applied in the directions of transportation and packaging, textile and papermaking, and conveying filamentous materials, etc., and can solve the problem of large and complex frame and spinning coiling device, installation and disassembly of silk supply unit Difficult, difficult to form a supporting wire feeding unit and other problems, to achieve the effect of easy adjustment, easy maintenance, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

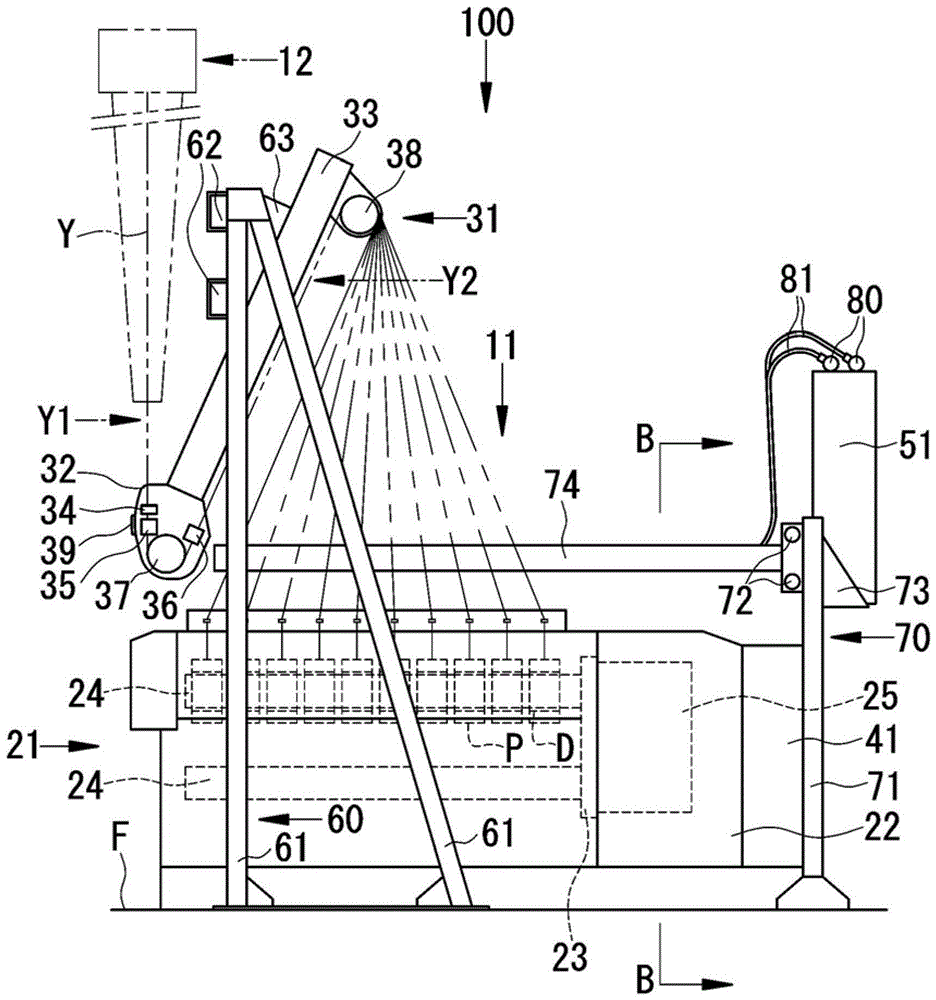

[0049] use Figure 1 to Figure 5 The spinning winding device 11 according to the first embodiment of the present invention and the spinning winding facility 100 configured by arranging a plurality of spinning winding devices 11 in a row will be described. In the following description, the free end side of the bobbin holder 24 to be described later will be referred to as the front side of the spinning winding device 11, and the opposite side thereof will be referred to as the rear side. A side surface of the spinning winding device 11 is defined as a surface viewed from the side of the bobbin holder 24 . In addition, the up-down direction refers to the up-down direction in a state in which the spinning winding device 11 is installed on a horizontal plane.

[0050] First, refer to figure 1 , figure 2 The spinning device 12 that supplies the yarn Y to the spinning take-up device 11 will be described. The spinning device 12 is a device that spins a plurality of filaments and ...

Embodiment 2

[0089] Second, use Figure 6 and Figure 7 The spinning winding device 11 according to the second embodiment of the present invention and the spinning winding device 100 configured by arranging a plurality of spinning winding devices 11 in a row will be described. The spinning take-up device 11 according to the present embodiment is a spinning take-up device for FDY that takes up FDY (drawn yarn). The detailed description of the configuration common to the first embodiment is omitted.

[0090] Such as Figure 6 as well as Figure 7 As shown, the spinning winding device 11 of this embodiment includes a yarn supply unit 31 . The yarn supply unit 31 of the spinning take-up device for FDY is a device that feeds the yarn Y toward the package forming unit 21 while heat-treating the plurality of yarns Y spun from the spinning device 12 . In the yarn supply unit 31, in addition to the first roller 37 and the second roller 38, a plurality of yarn processing rollers 91 to 96 are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com