Smooth processing device and smooth processing method of CL-20 grains

A CL-20, processing device technology, used in explosives processing equipment, offensive equipment, explosives, etc., can solve the problems of high cost, high cost, and difficulty in applying high-sensitivity energetic materials, and achieve reliable and smooth processing, safe and smooth. processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

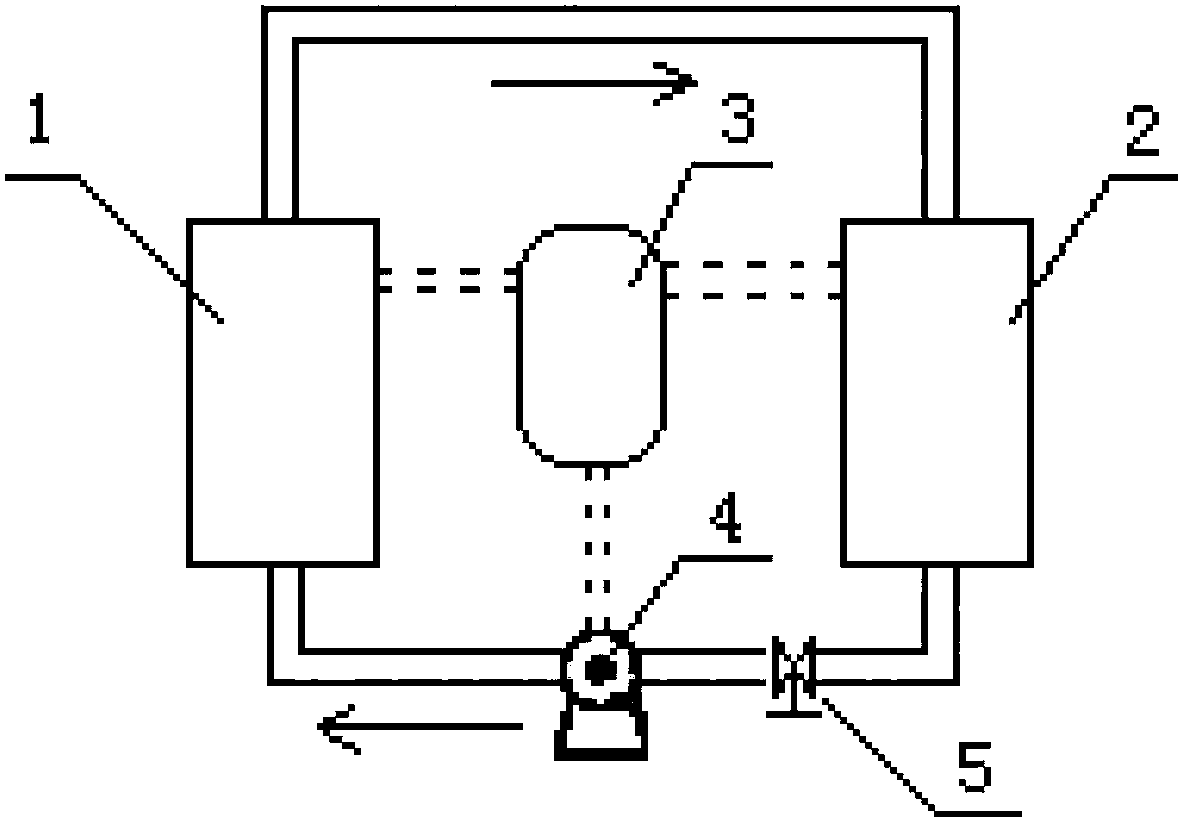

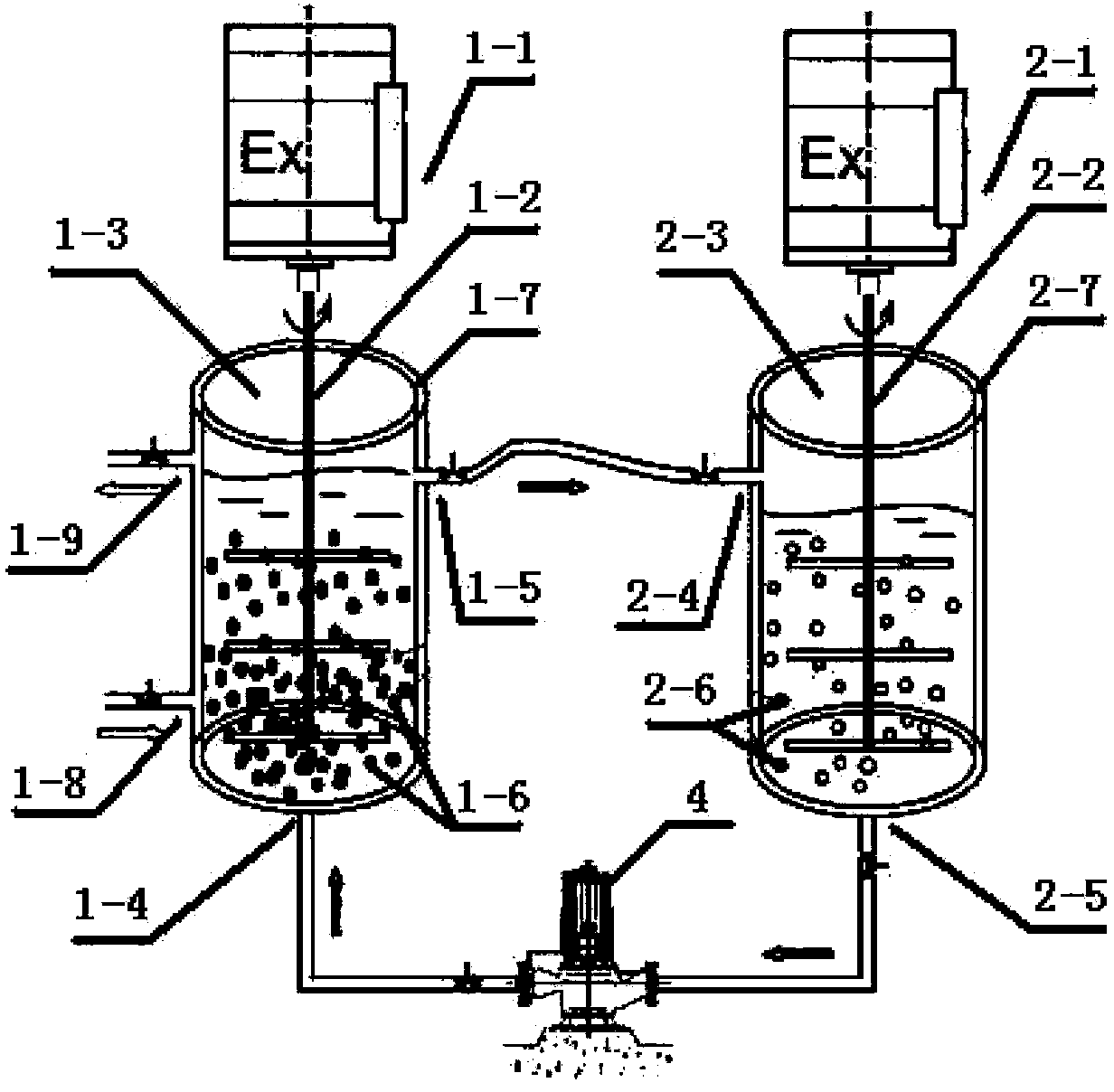

[0079] The specific implementation method of CL-20 particle smooth processing of the present invention is as follows:

[0080] raw material:

[0081] PTFE grinding ball: Density: 2.1g / cm 3 ; Shore D hardness: 55HD; Manufacturer: Nanjing Ives Chemical Products Co., Ltd.

[0082] Fluorosilicone rubber grinding ball: Density: 1.4g / cm 3 ; Shore A hardness: 70HA; Manufacturer: Chengdu Senfa Rubber & Plastic Co., Ltd.

[0083] Acetone: commercially available

Embodiment 1

[0085] 1. Weigh 2kg of polytetrafluoroethylene smooth grinding balls and add them to the grinding chamber of the smooth grinding equipment. The diameter of the grinding balls is 4mm, and the filling rate of the grinding chamber grinding balls is 75%; weigh 1.2kg of aged grinding balls of fluorosilicone rubber Add it into the aging chamber of the stirring aging equipment, the diameter of the aging grinding ball is 3mm, and the filling rate is 55%.

[0086] 2. Prepare the distilled aqueous solution of acetone as the grinding solvent liquid, and the weight percent concentration of acetone is 4%.

[0087] 3. Weigh 4kg of raw material CL-20, measure 9.3Kg of grinding solvent solution, fully mix the raw material CL-20 and grinding solvent to form a uniformly mixed slurry, and the concentration of CL-20 slurry is 30%wt.

[0088] 4. Input the uniformly mixed CL-20 slurry into the grinding chamber of the smooth processing equipment and the aging chamber of the stirring aging equipment ...

Embodiment 2

[0092] 1. Weigh 1.75kg polytetrafluoroethylene smooth grinding balls and add them to the grinding chamber of the smooth grinding equipment. The diameter of the grinding balls is 4mm, and the filling rate of the grinding chamber is 65%; Into the aging cavity of the stirring aging equipment, the aging grinding ball diameter is 3mm, and the filling rate is 50%.

[0093] 2. Prepare the distilled aqueous solution of acetone as the grinding solvent liquid, and the weight percent concentration of acetone is 4%.

[0094] 3. Weigh 4kg of raw material CL-20, measure 9.3Kg of grinding solvent solution, fully mix the raw material CL-20 and grinding solvent to form a uniformly mixed slurry, and the concentration of CL-20 slurry is 30%wt.

[0095] 4. Input the uniformly mixed CL-20 slurry into the grinding chamber of the smooth processing equipment and the aging chamber of the stirring aging equipment for circular smoothing treatment. The speed of the agitator in the smooth grinding chamber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com