Fiber array board assembly device and fiber array board assembly platform using same

A technology for optical fiber arrays and assembly devices, which is applied in the direction of workpiece clamping devices, connecting components, manufacturing tools, etc., can solve the problems of high operating skills and proficiency requirements for employees, long time for assembling array boards, and high operating level requirements. Achieve the effects of reducing costs, improving assembly production efficiency, and simplifying assembly operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

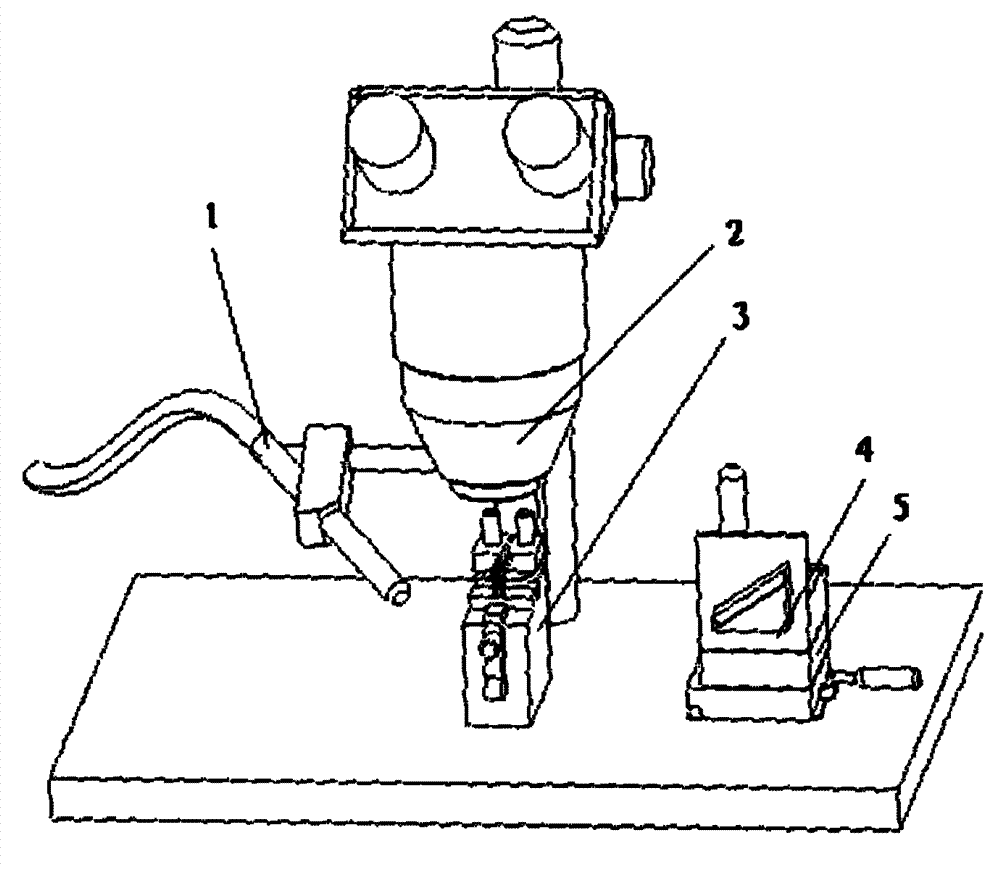

[0029] Figure 6 It is a schematic diagram of the overall structure of the optical fiber array plate assembly device in the present invention. The optical fiber array plate assembling device is composed of two parts, an L-shaped positioning base A and a clamp assembly B, and the two parts can be separated from each other.

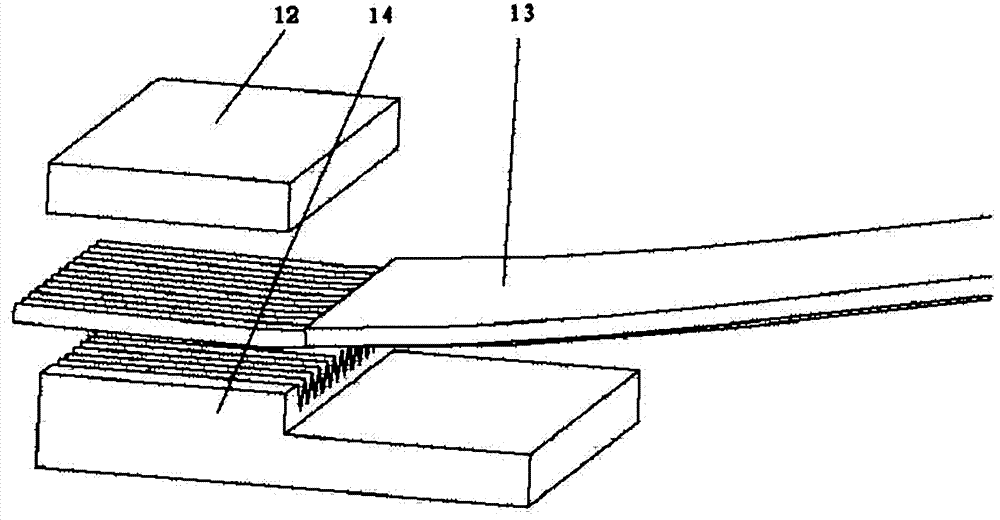

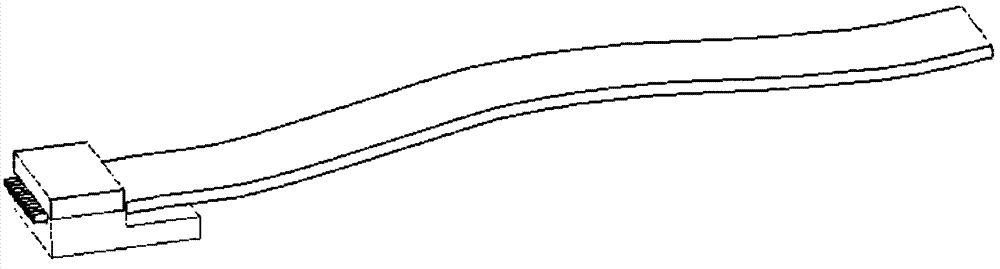

[0030] Figure 4A It is a structural schematic diagram of the above-mentioned L-shaped positioning base; the L-shaped positioning base A includes a side wall A1 and a base A2, the inside of the side wall is fixedly connected with a positioning block 6, and the inside of the side wall is also movably connected with a positioning block. 6 parallel pressing blocks 18, which can move horizontally along the inner side of the side wall to fix the array plate and press the optical fiber into the V-shaped groove of the array plate. A through hole 16a is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com