Measurement device and measurement method

A technology for measuring devices and measuring methods, applied in measuring devices, biological testing, material inspection products, etc., can solve problems such as differences in reaction time, and achieve the effect of preventing the reduction of processing capacity and avoiding the increase in volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

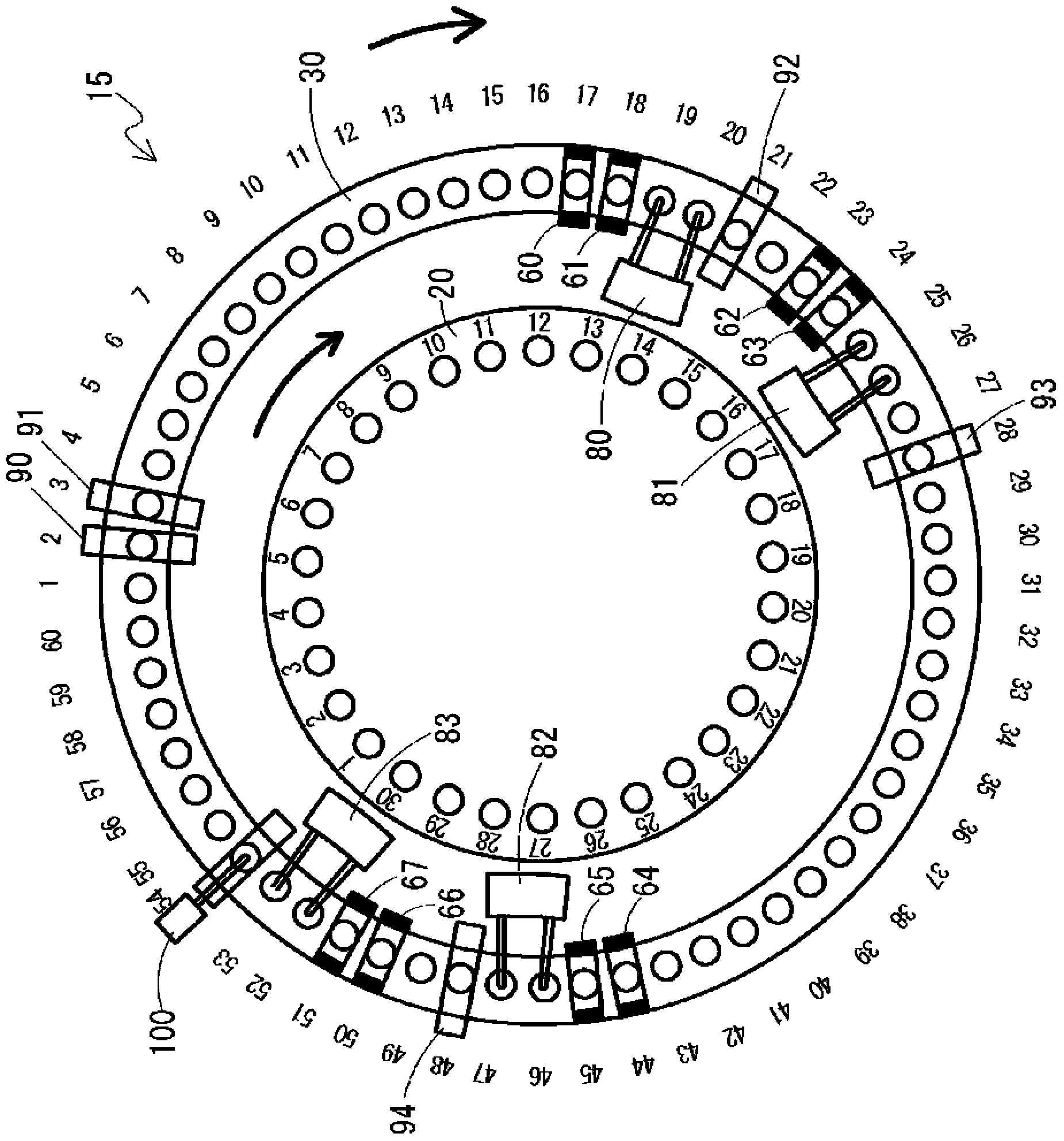

[0071] Embodiment 1 will be described first. This Embodiment 1 is a form in which the first reaction line and the second reaction line are installed on disc-shaped stages different from each other.

[0072] (composition - overall)

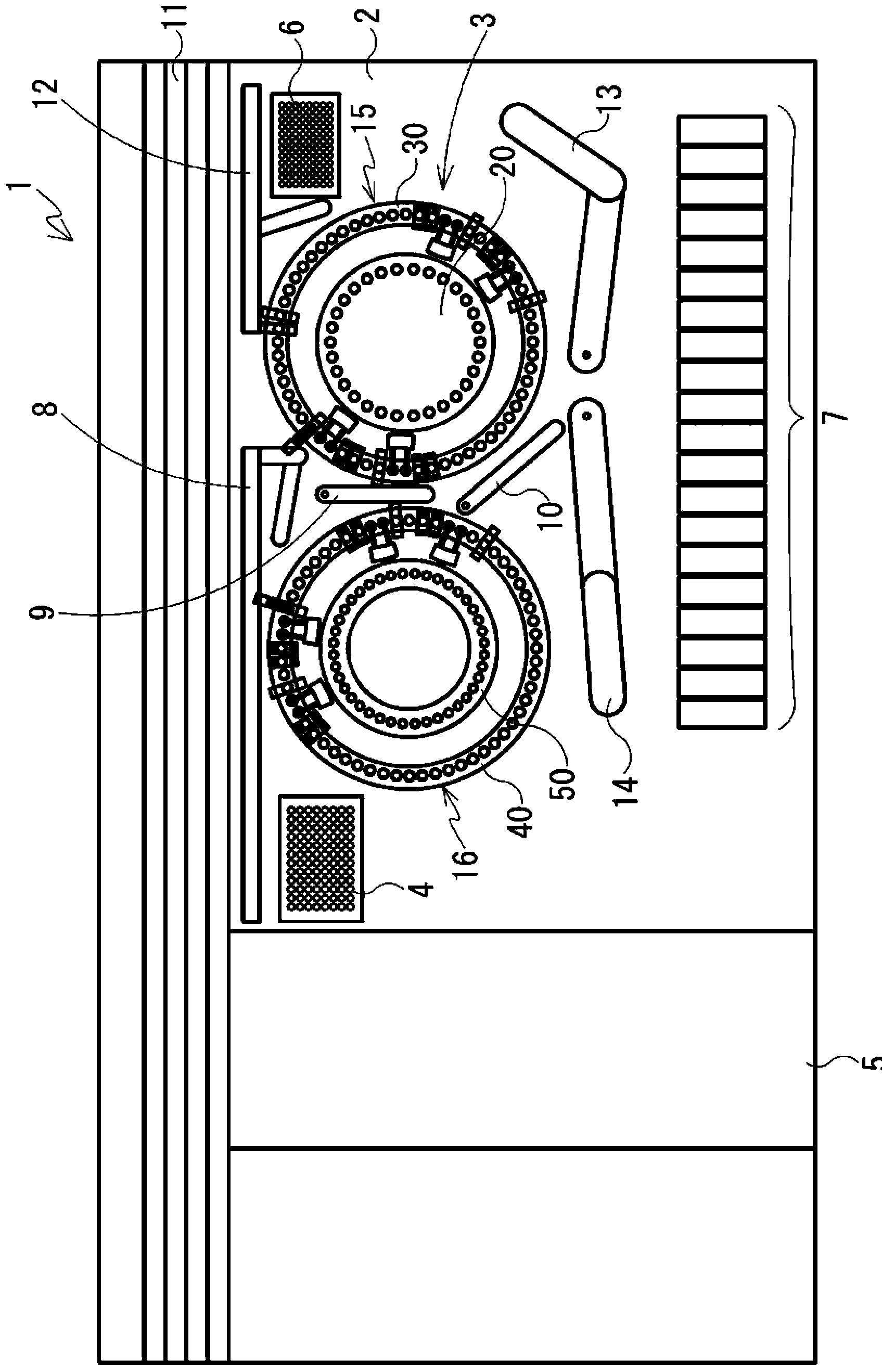

[0073] First, the overall configuration of the measurement device will be described. figure 1 It is a plan view of main parts of the measuring device according to the first embodiment. The measurement device 1 is an automatic immunoassay device, and is generally configured such that a measurement mechanism 3 is arranged on the upper part of the base surface 2, and the colorimetric tubes (not shown) are sequentially transported to a predetermined plurality of positions through the measurement mechanism 3, and the Each of these positions performs various predetermined operations to perform measurement, and the colorimetric tube is discarded after the measurement. In addition, the measurement device 1 may employ a configuration of a well-known auto...

Embodiment approach 2

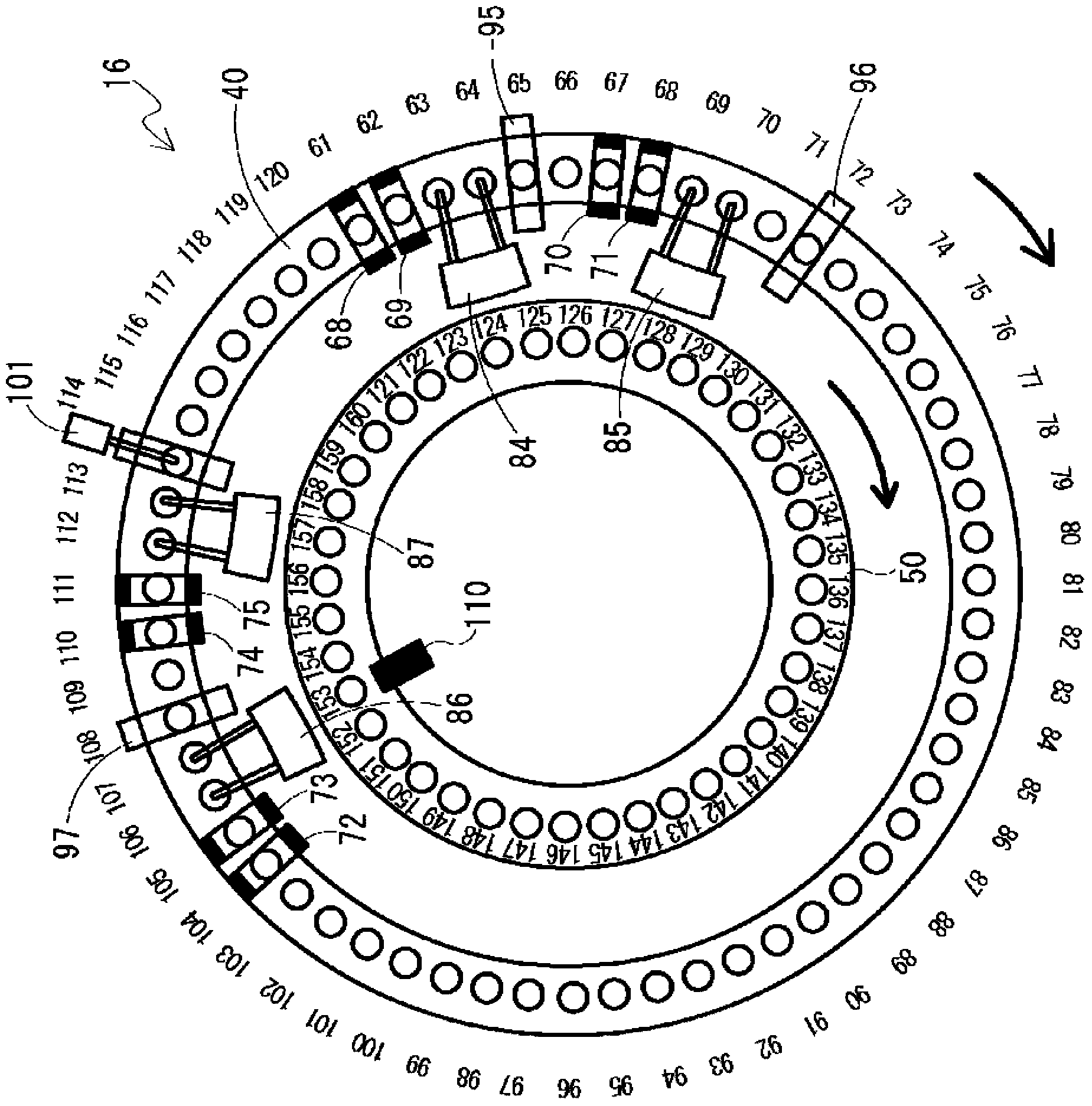

[0115] Next, Embodiment 2 will be described. This Embodiment 2 is a form in which only one reaction line is provided. Unless otherwise specified, the configuration is substantially the same as that of Embodiment 1, and the same symbols or names as those used in Embodiment 1 are used for configurations substantially the same as Embodiment 1 as necessary, and descriptions thereof are omitted (Embodiment 1). 3 to 4 are the same).

[0116] (constitute)

[0117] Figure 5 It is a plan view of main parts of the measuring device according to the second embodiment. In the configuration of this measuring device 200 , instead of the first stage 15 and the second stage 16 of the first embodiment, a first stage 201 , a second stage 202 , and a third stage 203 are provided. The first workbench 201 is provided with a pretreatment line 204 , the second workbench 202 is provided with a reaction line 205 and a reagent setting part 206 , and the third workbench 203 is provided with a measur...

Embodiment approach 3

[0126] Next, Embodiment 3 will be described. The third embodiment is a form in which the first reaction line and the second reaction line are provided as different linear transport mechanisms.

[0127] (constitute)

[0128] Image 6 It is a plan view of main parts of the measuring device according to the third embodiment. In the configuration of the measurement device 300, instead of the first stage 15 and the second stage 16 of the first embodiment, a first stage 301, a first reaction line 302, a second reaction line 303, a second stage 304, And reagent setting parts 305, 306. The first workbench 301 is provided with a pretreatment line 307 , and the second workbench 304 is provided with a measurement line 308 .

[0129] The pretreatment line 307 is a line for performing pretreatment and dilution of samples. The first reaction line 302 and the second reaction line 303 are respectively the production lines for carrying out the reaction between the sample and the magnetic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com