Cemented filling close to back processing technology for goaf at barren rock filling background

A technology for cemented filling and goaf, which is used in filling materials, mining equipment, and earth-moving drilling and mining, etc., can solve the problems of fine grain size, poor permeability, serious shrinkage and deformation of all tailings, and achieves the best results. The effect of low economic cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

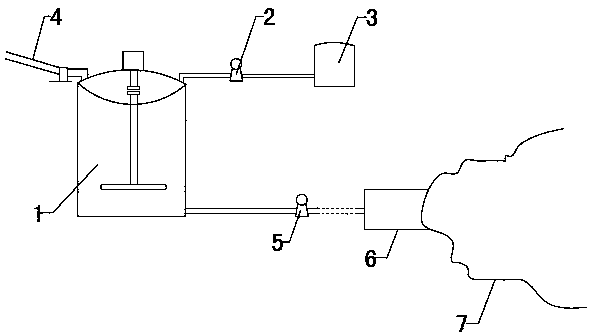

[0047] Weigh the iron tailings and glue solid powder on the ground surface according to the mass ratio of 6:1, put them into the mixer and mix them evenly, then calculate the amount of water added based on the total amount of materials added, put them into the mixer with a metering pump, and mix them so that the mass concentration is 51 % of filling slurry; the well-stirred filling slurry is transported downhole through the existing filling pipeline.

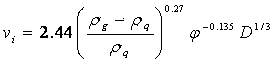

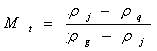

[0048] On the plane of -280m underground iron ore goaf, according to the calculation of the flow velocity of 51% of the filling slurry pipeline and the coagulation time determined by the small test, it is determined to add metering pumps, mixing barrels, accelerator storage tanks and 80m away from the goaf The filling slurry transported to the downhole through the filling pipeline enters the mixing tank, and at the same time, the liquid sodium aluminate quick-setting agent is added through the metering pump and the addition ratio...

Embodiment 2

[0052] Weigh the iron tailings and glue solid powder on the ground surface according to the mass ratio of 6:1, put them into the mixer and mix them evenly, then calculate the amount of water added based on the total amount of materials added, put them into the mixer with a metering pump, and mix them so that the mass concentration is 51.4 % of filling slurry; the well-stirred filling slurry is transported downhole through the existing filling pipeline.

[0053] In the plane where the mined-out area is -220m underground, according to the calculation of the flow rate of the filling slurry pipeline of 51.4% and the setting time determined by the small test, it is determined to add a metering pump, a mixing tank, an accelerator storage tank and a connection at a distance of 90m from the mined-out area. Pipeline, the filling slurry transported to the downhole through the filling pipeline enters the mixing tank, and at the same time, the liquid sodium aluminate quick-setting agent is...

Embodiment 3

[0057] Weigh the iron tailings and glue solid powder on the ground surface according to the mass ratio of 6:1, put them into the mixer and mix them evenly, then calculate the amount of water added based on the total amount of materials added, put them into the mixer with a metering pump, and mix them so that the mass concentration is 51 % of filling slurry; the well-stirred filling slurry is transported downhole through the existing filling pipeline.

[0058] In the plane where the mined-out area is -280m underground, according to the calculation of the flow velocity of the filling slurry pipeline of 51% and the coagulation time determined by the small test, it is determined to add a metering pump, a mixing tank, an accelerator storage tank and a connection at a distance of 100m from the mined-out area. Pipeline, the filling slurry transported to the downhole through the filling pipeline enters the mixing tank, and at the same time, the liquid sodium aluminate quick-setting age...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com