High-temperature high-pressure steam-liquid double-flow rope-shaped dyeing machine

A rope dyeing machine, high temperature and high pressure technology, applied in liquid/gas/vapor rope fabric processing, liquid/gas/vapor jet propulsion fabric, liquid/gas/vapor processing indefinite length textile materials, etc., can solve the restriction efficiency , effect, reducing the bath ratio, restrictions and other issues, to achieve the effect of improving efficiency, strong texture, and reducing sewage discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical solutions of the present invention will be further specifically described below through specific embodiments and in conjunction with the accompanying drawings.

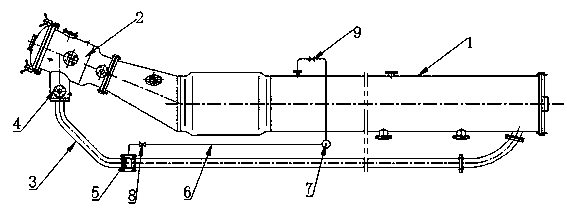

[0012] Such as figure 1 As shown, a high-temperature and high-pressure vapor-liquid double-flow rope dyeing machine (cloth guide tube down-moving type), including a cylinder body 1, a cloth guide head 2, and a cloth guide tube 3, the cloth guide head is arranged at the front end of the cylinder body, and the cloth guide head is below the cloth guide head. A nozzle installation pipe is provided, and a liquid flow nozzle 4 is arranged in the nozzle installation pipe. The airflow pipe 6 is connected to the airflow nozzle of the cloth guide pipe, an airflow pump 7 is arranged in the middle of the airflow pipe, and a first airflow regulating valve 8 is arranged in the airflow pipe. The air flow pipeline is also provided with a second air flow control valve 9 .

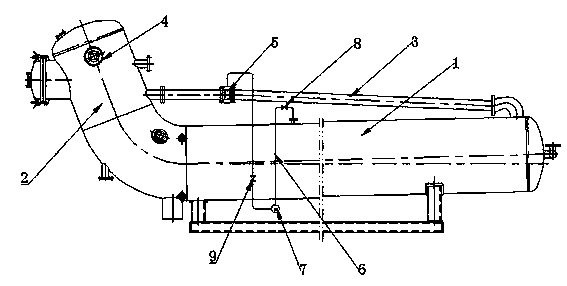

[0013] Such as figure 2 As described...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com