Cycloamylose preparation method based on starch debranching method

A technology of macrocyclodextrin and starch, which is applied in the field of preparation of macrocyclodextrin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

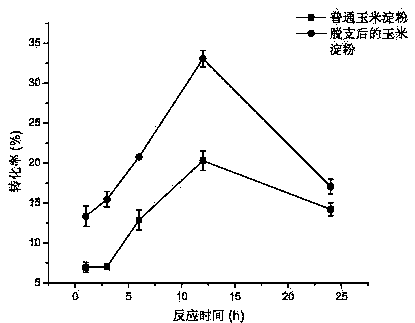

[0030] Example 1 Production of macrocyclodextrin by debranching method from common corn starch

[0031] Concrete preparation steps are as follows:

[0032] (1) Debranching pretreatment of corn starch and preparation of 1wt% starch solution: Weigh 10 mg of ordinary corn starch (purchased from Hangzhou Prostar Starch Co., Ltd.), add 1 ml of 90% dimethyl sulfoxide, and place in boiling water bath for 1 h Magnetically stir overnight at room temperature, then add 6 times the volume of absolute ethanol, centrifuge at 5000rpm for 10min, discard the supernatant, add 1ml of preheated sodium acetate buffer (50mM, pH 3.5) to the resulting precipitate, and boil for 30min. Obtain 1wt% common corn starch solution.

[0033] (2) Debranching of common corn starch: Add 7.5U / g isoamylase (purchased from Megazyme, Ireland) to the 1wt% common corn starch solution prepared in step (1), and debranch at 40°C and pH 3.5. Branch for 12 hours, then inactivate the enzyme in a boiling water bath for ...

Embodiment 2

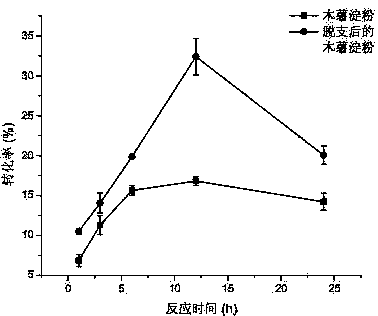

[0040] Example 2 Production of macrocyclodextrin by debranching method of common tapioca starch

[0041] Concrete preparation steps are as follows:

[0042] (1) Debranching pretreatment of tapioca starch and preparation of 1wt% starch solution: Weigh 10 mg of ordinary tapioca starch (purchased from Hangzhou Prostar Starch Co., Ltd.), add 1 ml of 90% dimethyl sulfoxide, and place in a boiling water bath for 1 h Magnetically stir overnight at room temperature, then add 6 times the volume of absolute ethanol, centrifuge at 5000rpm for 10min, discard the supernatant, add 1ml of preheated sodium acetate buffer (50mM, pH 3.5) to the resulting precipitate, and boil for 30min. Obtain 1wt% common tapioca starch solution.

[0043] (2) Debranching of ordinary tapioca starch: add 5U / g isoamylase (same as above) to the 1wt% ordinary tapioca starch solution prepared in step (1), debranch at 40°C and pH 3.5 for 12 hours, then boil water Bath for 10min to inactivate the enzyme.

[0044]...

Embodiment 3

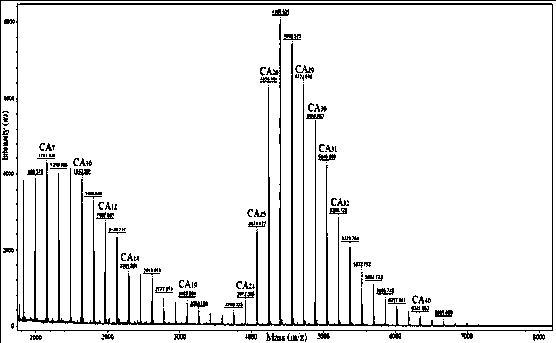

[0050] Example 3 Production of Macrocyclodextrin by Debranching High Amylose Corn Starch

[0051] Concrete preparation steps are as follows:

[0052] (1) Debranching pretreatment of high-amylose corn starch and preparation of 1wt% starch solution: Weigh 10 mg of high-amylose corn starch (purchased from Hangzhou Prostar Starch Co., Ltd.), add 1 ml of 90% dimethyl sulfoxide, and bathe in boiling water for 1 h Magnetically stir overnight at room temperature, then add 6 times the volume of absolute ethanol, centrifuge at 5000rpm for 10min, discard the supernatant, add 1ml of preheated sodium acetate buffer (50mM, pH 3.5) to the resulting precipitate, and boil for 30min Promptly get 1wt% high amylose corn starch solution.

[0053] (2) Debranching of high-amylose corn starch: Add 10 U / g isoamylase (same as above) to the 1wt% high-amylose corn starch solution prepared in step (1), debranch at 40°C and pH 3.5 for 12 hours, then boil water Bath for 10min to inactivate the enzyme. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com