Preparation method of casein-based hollow microsphere polymer film-forming material

A technology of film-forming materials and polymers, which is applied in the field of preparation of modified casein hollow polymers, can solve problems such as not meeting the theme of green environmental protection, difficulty in forming films at glass transition temperature, lower safety and environmental protection, and achieve improvement Hard and brittle film formation, good hygienic performance, and the effect of increasing added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

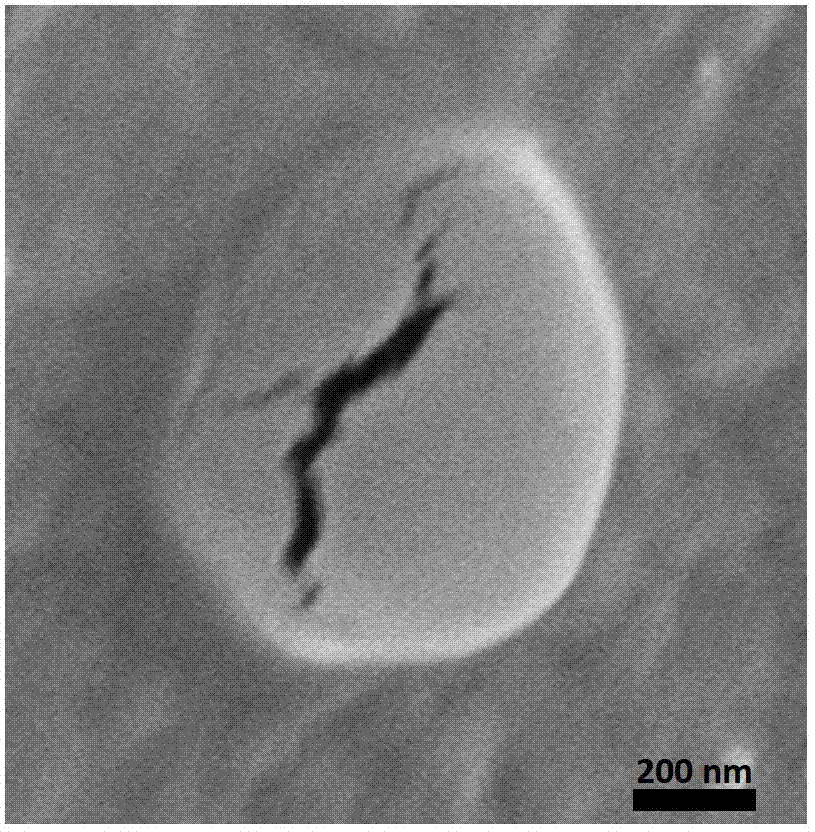

[0024] 1) Preparation of core-shell emulsion:

[0025]Taking the mass of the core-shell emulsion as 100 parts, a three-necked flask equipped with a stirring rod and a condenser was heated to 61° C. in a water bath, and then 6.9 parts of casein, 1.6 parts of triethanolamine, and 43.3 parts of triethanolamine were added. Ionized water, until the casein is dissolved to obtain a mixed solution; then the mixed solution is heated up to 72°C, and 32.0 parts of caprolactam aqueous solution with a concentration of 0.75mol / L is added dropwise to the mixed solution within 30 minutes, and stirred for 90 minutes to obtain the reaction system A; Add 2.4 parts of mixed monomer A which is mixed with methacrylic acid, methyl methacrylate and butyl acrylate with a mass ratio of 4:10:5 and 1.0 part of supernatant with a concentration of 0.44mol / L to reaction system A. Ammonium sulfate aqueous solution, heat preservation reaction at 72°C for 60min to obtain a stable seed emulsion; raise the tempe...

Embodiment 2

[0029] 1) Preparation of core-shell emulsion:

[0030] Taking the mass of the core-shell emulsion as 100 parts, a three-necked flask equipped with a stirring bar and a condenser was heated to 62°C in a water bath in terms of parts by mass, and then 7.1 parts of casein, 1.9 parts of triethanolamine, and 42.8 parts of triethanolamine were added. Ionized water, after the casein is dissolved, a mixed solution is obtained; then the mixed solution is heated to 74°C, and 32.5 parts of a caprolactam aqueous solution with a concentration of 0.75mol / L is added dropwise to the mixed solution within 30 minutes, and stirred for 100 minutes to obtain the reaction system A ; Add 2.1 parts of mixed monomer A and 1 part of concentration of 0.44mol / L to the reaction system A by adding methacrylic acid, methyl methacrylate and butyl acrylate in a mass ratio of 4:10:5 The ammonium persulfate aqueous solution was incubated at 74°C for 70 minutes to obtain a stable seed emulsion; the temperature of...

Embodiment 3

[0034] 1) Preparation of core-shell emulsion

[0035] Taking the mass of the core-shell emulsion as 100 parts, a three-necked flask equipped with a stirring rod and a condenser was heated to 63°C in a water bath in terms of parts by mass, and then 7.3 parts of casein, 2.2 parts of triethanolamine, and 42.3 parts of Ionized water, after the casein is dissolved, a mixed solution is obtained; then the mixed solution is heated to 76°C, and 33 parts of a caprolactam aqueous solution with a concentration of 0.75mol / L is added dropwise to the mixed solution within 30 minutes, and stirred for 110 minutes to obtain the reaction system A Add 1.8 parts of methacrylic acid, methyl methacrylate and butyl acrylate mixed in the reaction system A by 1.8 parts by mass ratio and the mixed monomer A and 1.0 degrees are 0.44mol / L Aqueous solution of ammonium persulfate was incubated at 76°C for 80 minutes to obtain a stable seed emulsion; the water bath of the seed emulsion was raised to 83°C, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com