Mesh opening shell cover and forming method tehreof

A molding method and mesh technology, applied in the direction of cabinets/cabinets/drawer parts, etc., can solve the problems of complex steps, long molding time, and unfavorable long-term development of enterprises, and achieve increased sensitivity, simple structure, and high-quality products. The effect of appearance diversification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The molding method of mesh shell cover, comprises steps:

[0042] (a) preparatory process: select the required stainless steel material for making grille 1;

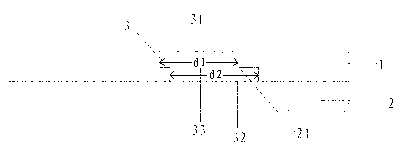

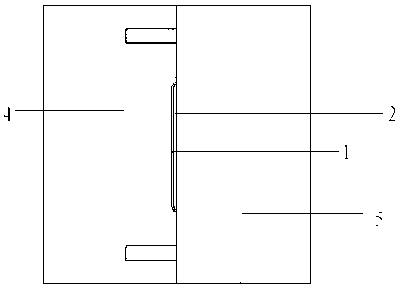

[0043] (b) Dislocation double-sided etching: the stainless steel material is subjected to double-sided etching treatment, so that a mesh 3 is formed on the stainless steel material, such as figure 1 The front hole 31 and the back hole 32 of the shown mesh 3 are circular holes, the front hole 31 of the mesh 3 has an aperture diameter of 0.3mm, and the back hole 32 has an aperture of 0.5mm, and the front hole 31 and the back hole 32 are dislocated Distribution, a back hole 32 corresponds to a front hole 31, the intersection of the front hole 31 and the back hole 32 is a through hole 33, the cross-sectional area of the through hole 33 is 94% of the cross-sectional area of the front hole 31, and the mesh 3 forms Snap-shaped cavity;

[0044] (c) stamping forming: the stainless steel material described in step (b...

Embodiment 2

[0050] A method for forming a mesh shell cover, comprising the steps of:

[0051] (a) preparatory process: select the required stainless steel material for making grille 1;

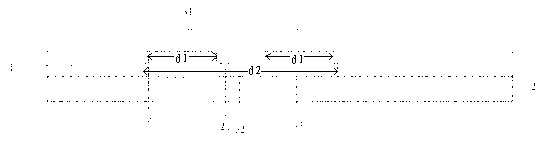

[0052] (b) Dislocation double-sided etching: the stainless steel material is subjected to double-sided etching treatment, so that a mesh 3 is formed on the stainless steel material, such as image 3 The front hole 31 of the mesh 3 is a circular hole, and the back hole 32 is an oval hole. The front hole 31 of the mesh 3 has an aperture diameter of 0.3mm, and the back hole 32 has an elliptical aperture of 1.15mm*0.45mm. The front hole 31 and the back hole 32 are misplaced, so that the mesh 3 forms a snap-shaped cavity, and one back hole 32 corresponds to two front holes 31, and the intersection of the front hole 31 and the back hole 32 is a through hole 33, and the through hole 33 The cross-sectional area is 87% of the cross-sectional area of the front hole 31, and the mesh 3 forms a buckle-shaped cavity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com