Method for independently controlling all phases of transverse magnetic flux motor

A transverse flux motor, independent control technology, applied in the direction of electronic commutation motor control, motor generator control, control system, etc., can solve the interphase current and electromagnetic torque imbalance, phase difference imbalance, interphase back electromotive force magnitude Inequality and other problems, to achieve the effect of reducing torque ripple and vibration noise, and solving torque and current imbalance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In conjunction with the accompanying drawings and embodiments, the technical solution of the present invention is further specifically described as follows:

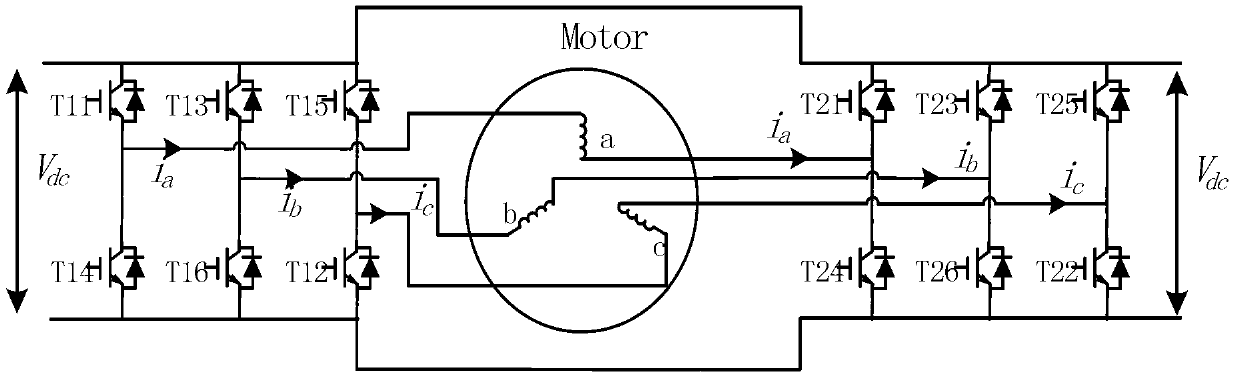

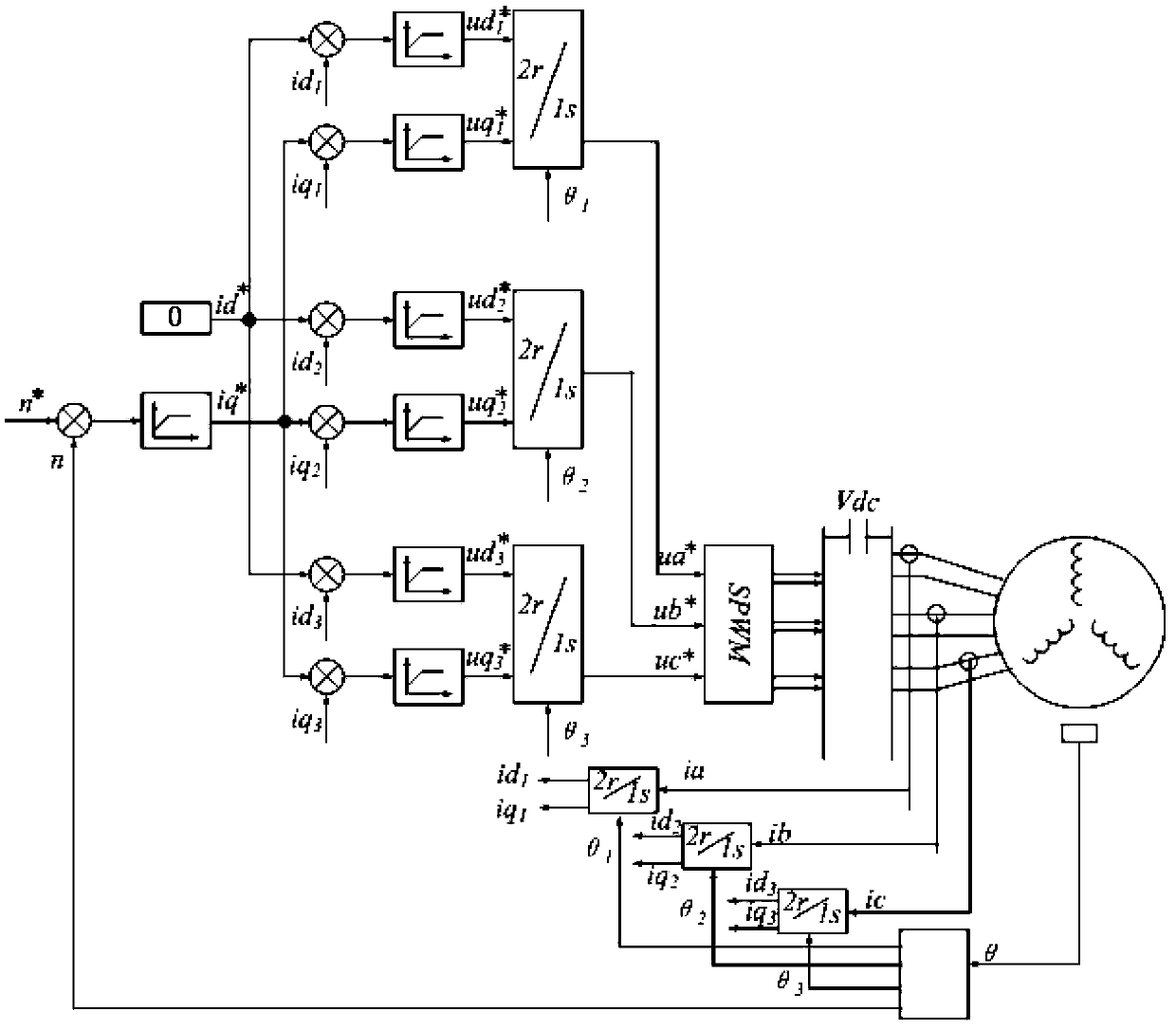

[0026] as attached Figure 1 to Figure 5 As shown, an independent control method for each phase of a transverse flux motor, which completely decouples the transverse flux motor driven by the H bridge drive system, realizes independent control of each phase in the full speed range of the transverse flux motor, and achieves Torque and current balance between phases. The phases are controlled independently, and the current component values input by the current loop are the same; the current component values input by the current loop are torque current component reference value and excitation current component reference value respectively. The independent control of each phase is that each phase independently performs single-phase current vector coordinate transformation, current loop control and output control. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com