Automatic bonding device of Halbach permanent magnet array

A technology of automatic bonding and permanent magnet array, applied in the manufacture of stator/rotor body, etc., can solve the problems of high risk, low efficiency, few and few, etc., and achieve the effect of efficient manufacturing process, simple structure and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with specific embodiment, further illustrate the present invention.

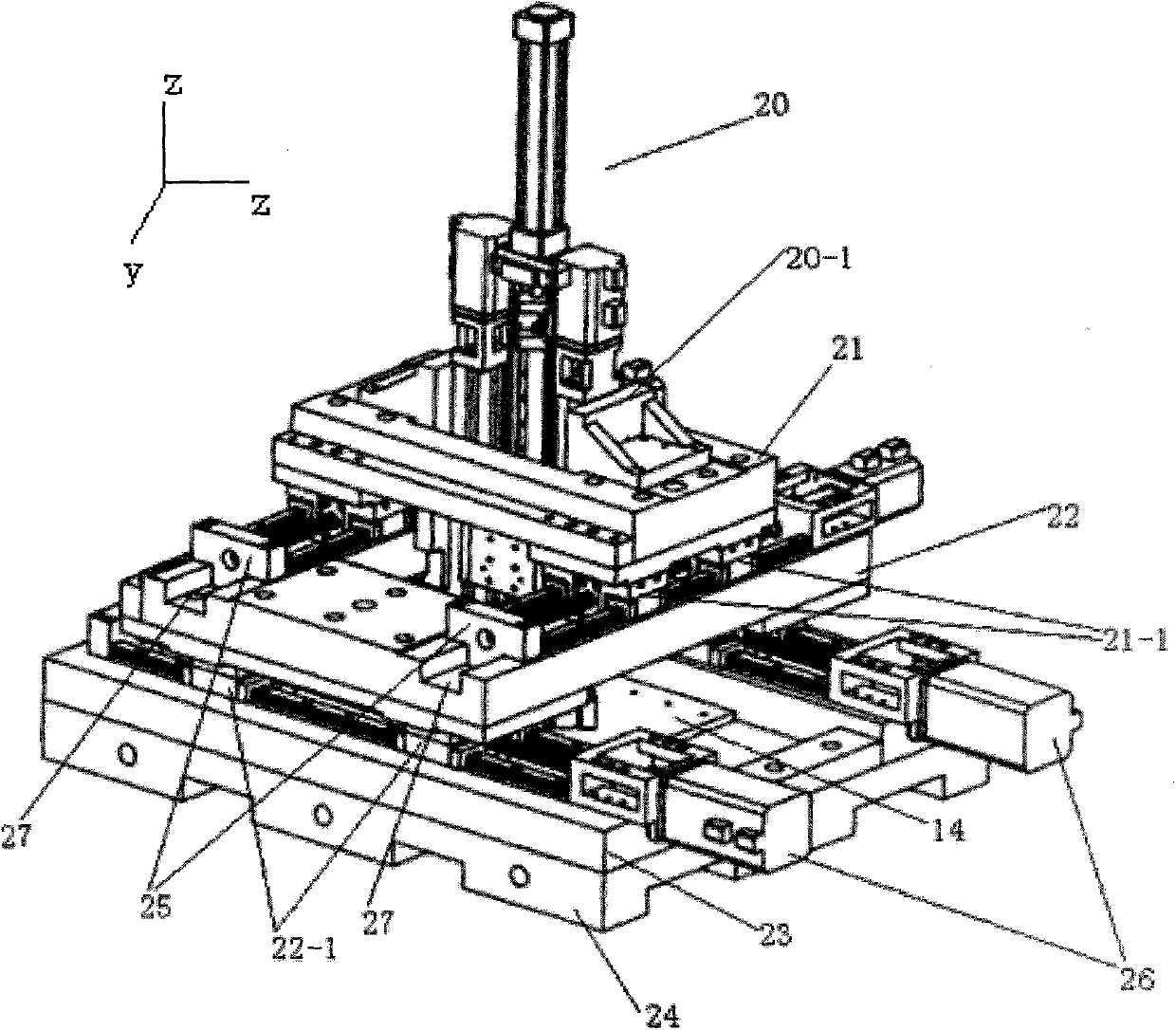

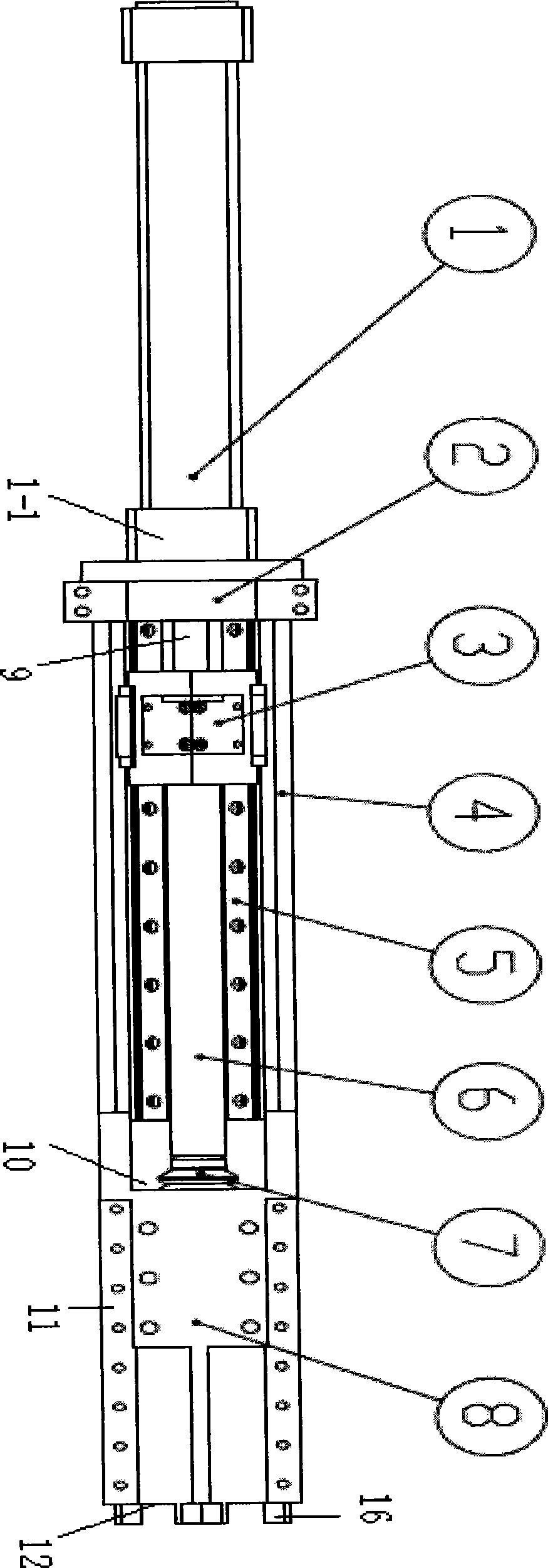

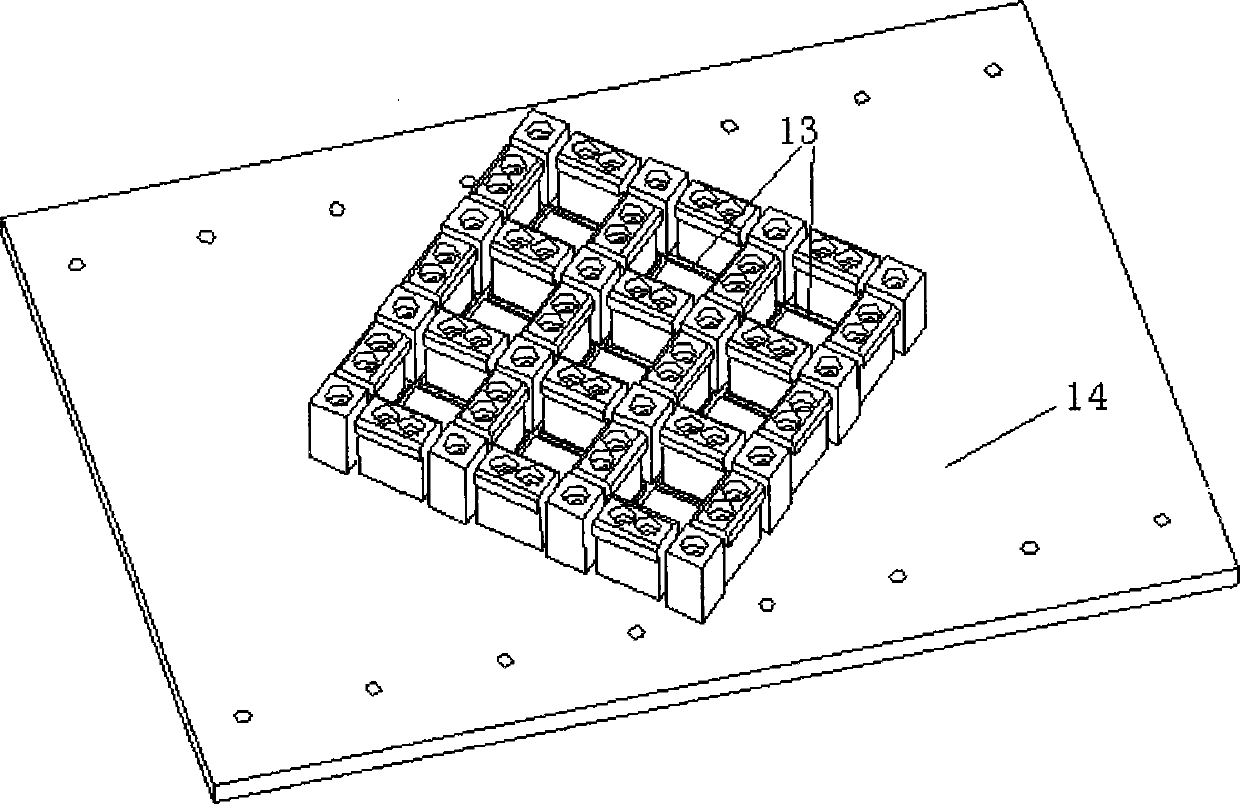

[0029] Such as Figure 1-4 Shown: a kind of automatic bonding equipment of Halbach permanent magnet array, including cube magnetic steel pushing mechanism (20), supporting part (20-1), first platform (21), second platform (22), third platform (23), base (24) and magnetic steel backboard (14), it is characterized in that:

[0030] The support member (20-1) is located on the top of the first platform (21), and is used to support the cube magnet pushing mechanism (20) so that the cube magnet pushing mechanism (20) can move up and down along the Z axis;

[0031] The first platform (21) is located on the second platform (22), the first ball screw (21-1) is fixed on both sides of the bottom of the first platform (21), and the upper part of the second platform (22) Both sides have a first chute (27), and the upper part of the chute has a first rolling guide rail (25), and the first rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com