Cube magnetic steel pushing mechanism based on Halbach permanent magnet array

A push mechanism and permanent magnet array technology, applied in the manufacture of stator/rotor body, etc., can solve the problems of time-consuming manual bonding, low efficiency, poor precision, etc., and achieve the effect of high-efficiency manufacturing process, convenient operation and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with specific embodiment, further illustrate the present invention.

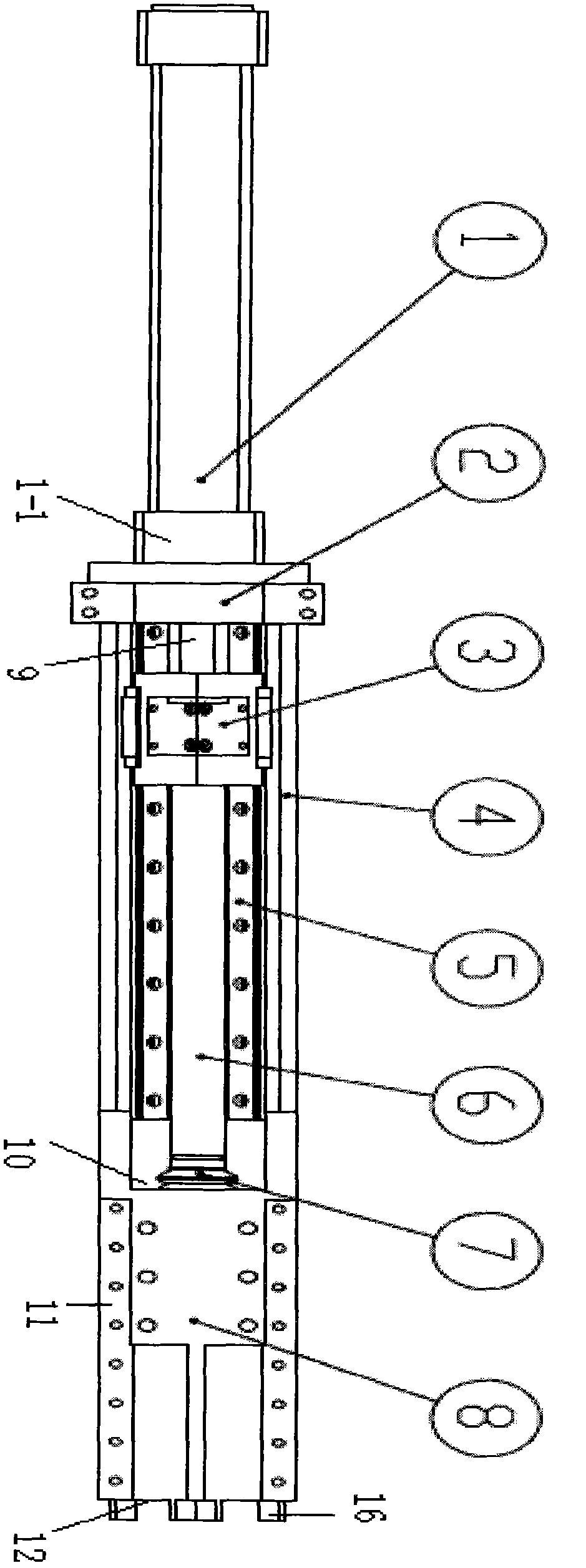

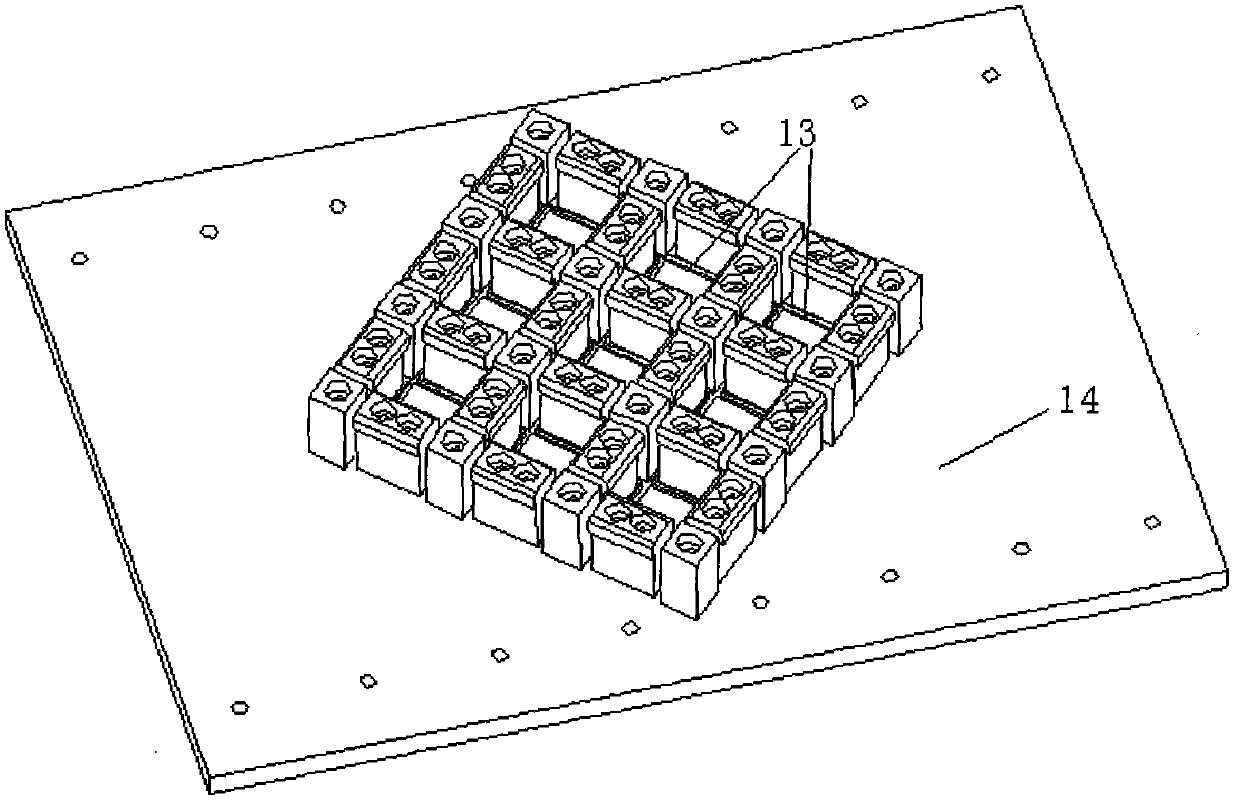

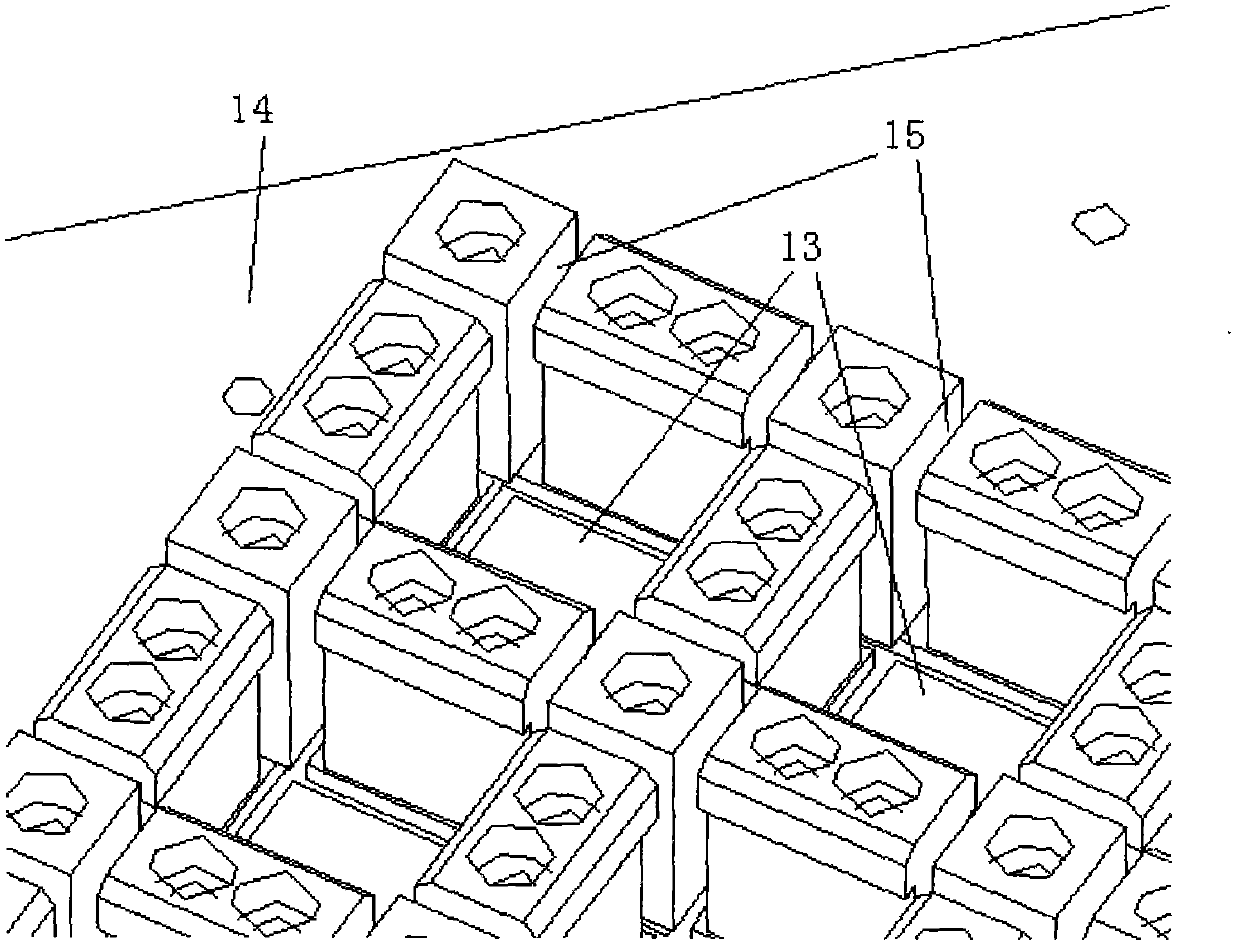

[0020] Such as Figure 1-3 Shown: a cube magnetic steel push mechanism, which sequentially includes a power supply part, a guide rail buffer part and a magnetic steel push channel, is characterized in that,

[0021] The power supply part includes a cylinder (1), a cylinder block (1-1) and a cylinder mounting plate (2);

[0022] The buffer part of the guide rail includes a slider (3), a sleeve (4), a guide rail (5), a push rod (6), a cylinder push rod (9) and a buffer suction cup (7);

[0023] The magnetic steel push channel includes a magnetic steel inlet (10), a sleeve front cover (8), a sleeve front end (11) and a magnetic steel push outlet (12);

[0024] The cylinder (1) is connected to the cylinder push rod (9) through the cylinder block (1-1) and the cylinder mounting plate (2), and the cylinder push rod (9) passes through the slide block (3) and the ejector rod (6) ), the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com