Improved acid adding machine

An acid feeder and improved technology, applied in structural parts, electrical components, battery pack parts and other directions, can solve the problems of unreasonable design of conveying mechanism and acid feeding mechanism, affecting work efficiency, and occupying a large space for production lines, etc. Optimize the effect of heavy workload, high degree of automation, and large labor consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

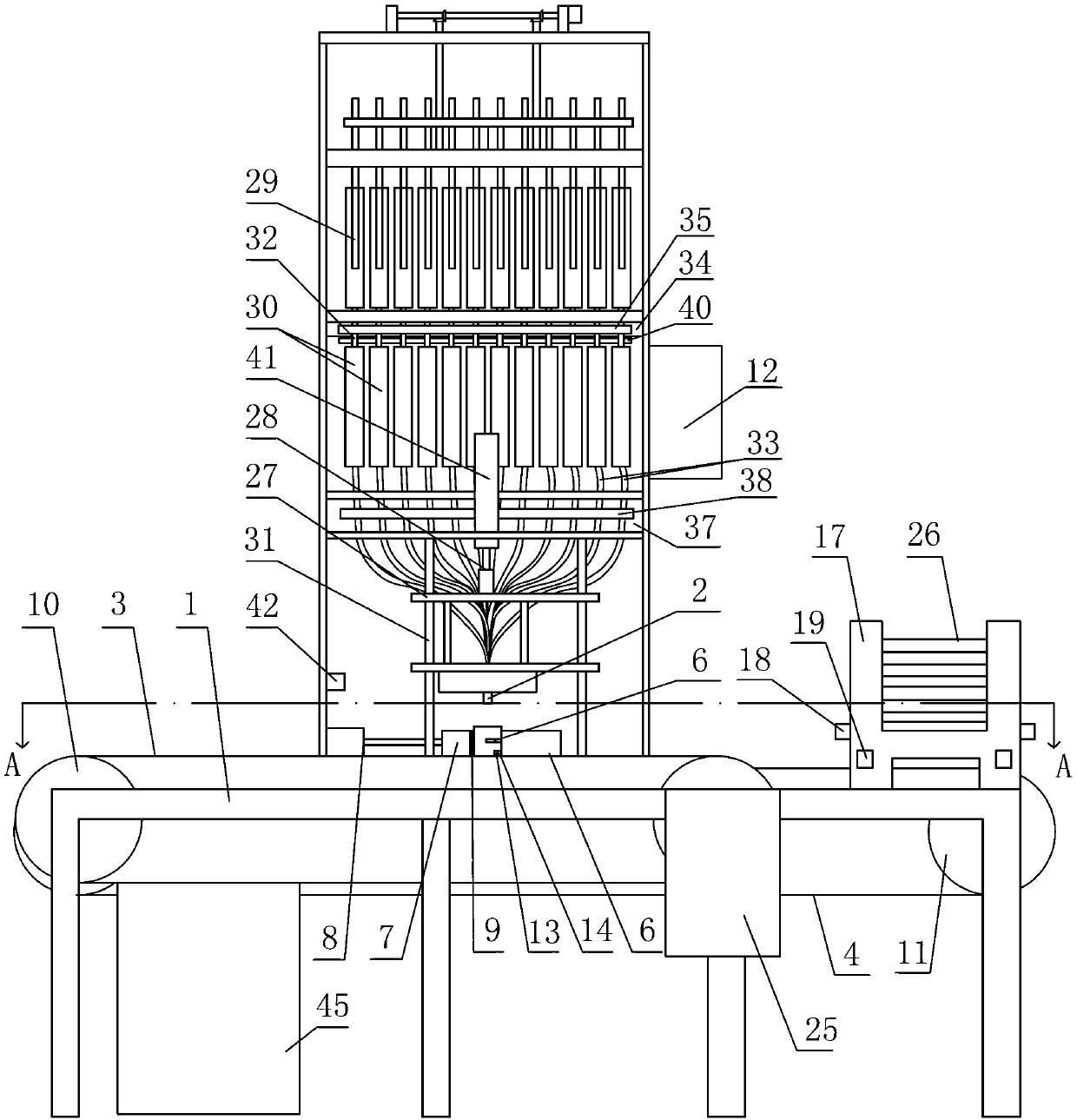

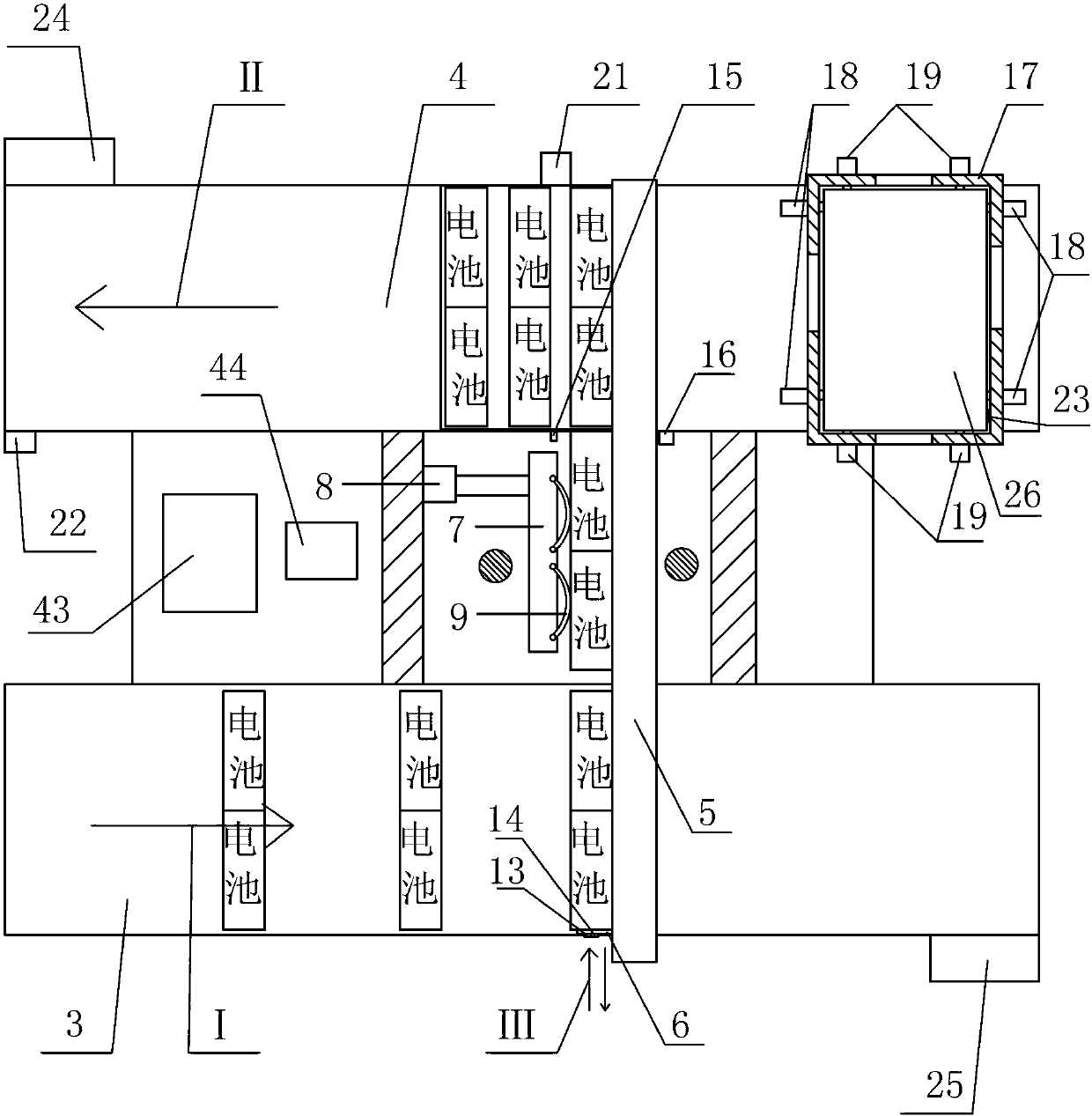

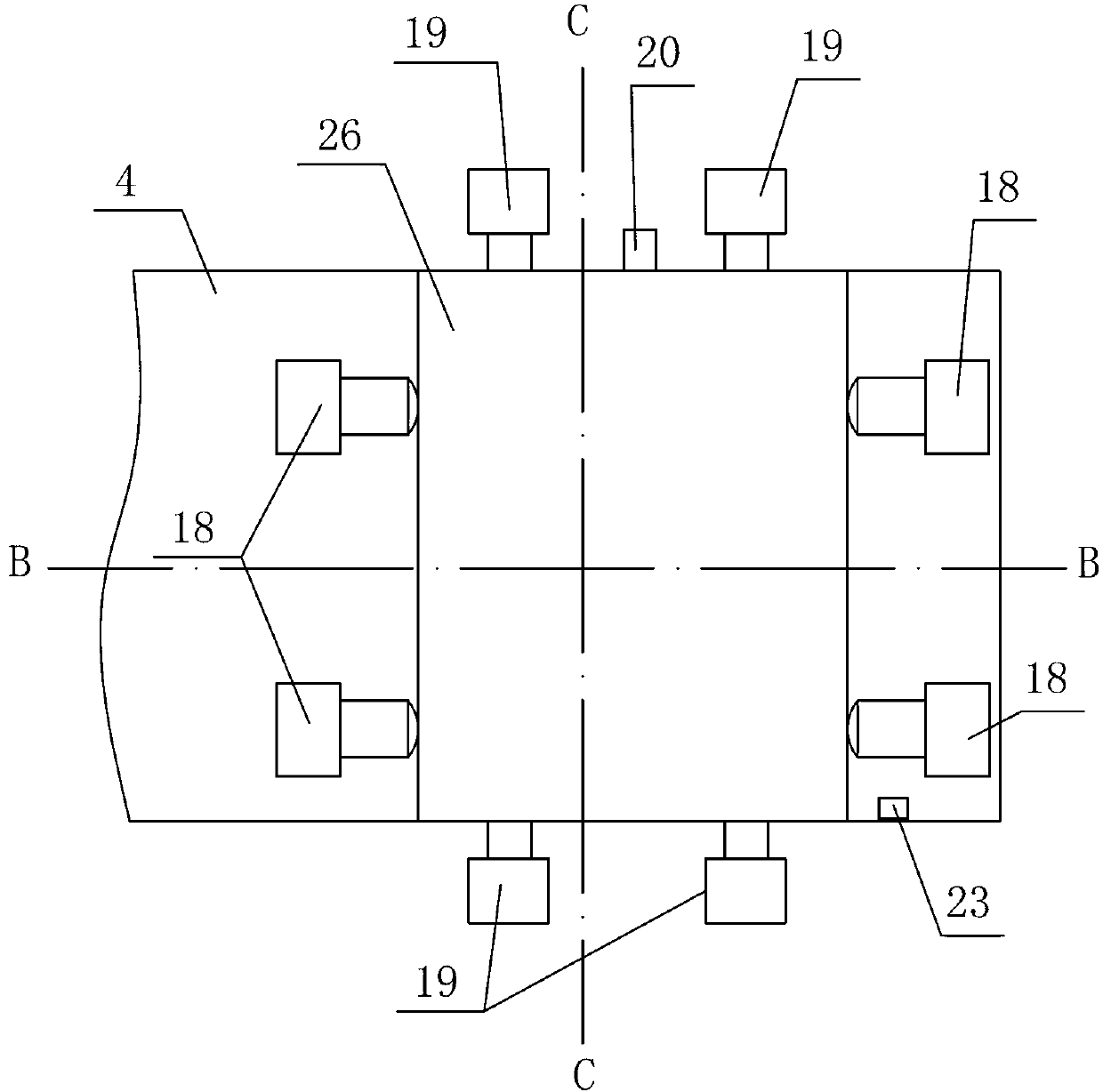

[0021] Such as Figures 1 to 7 As shown, the improved acid adding machine includes a body 1 and an acid adding mechanism. The acid adding mechanism includes an acid injection head 2 arranged on the body. Conveyor belt II4 for the battery, the machine body is equipped with a device for pushing the battery to be injected on the conveyor belt I3 to the bottom of the acid injection head 2 and pushing the battery after acid injection under the acid injection head 2 to the conveyor belt II4 Pushing mechanism, the body is located under the acid injection head 2 and is equipped with a fixing mechanism for clamping and positioning the battery to be injected. The body is equipped with a tray frame 17 that runs through the top and bottom of the conveyor belt II4. The bottom of the tray frame 17 is open, preferably a tray Frame 17 is the frame body of bottom opening, and tray 26 is placed on the tray frame 17 and is positioned at opening directly above, and tray frame 17 is placed in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com