Label inserting control system and method

A control method and the technology of the inserter, which are applied in the direction of digital control and electrical program control, etc., can solve the problems of too short labels, inconspicuous marks, shortening the service life of relays and cutter heads, etc., so as to prolong the service life and avoid The effect of label paper being too short

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

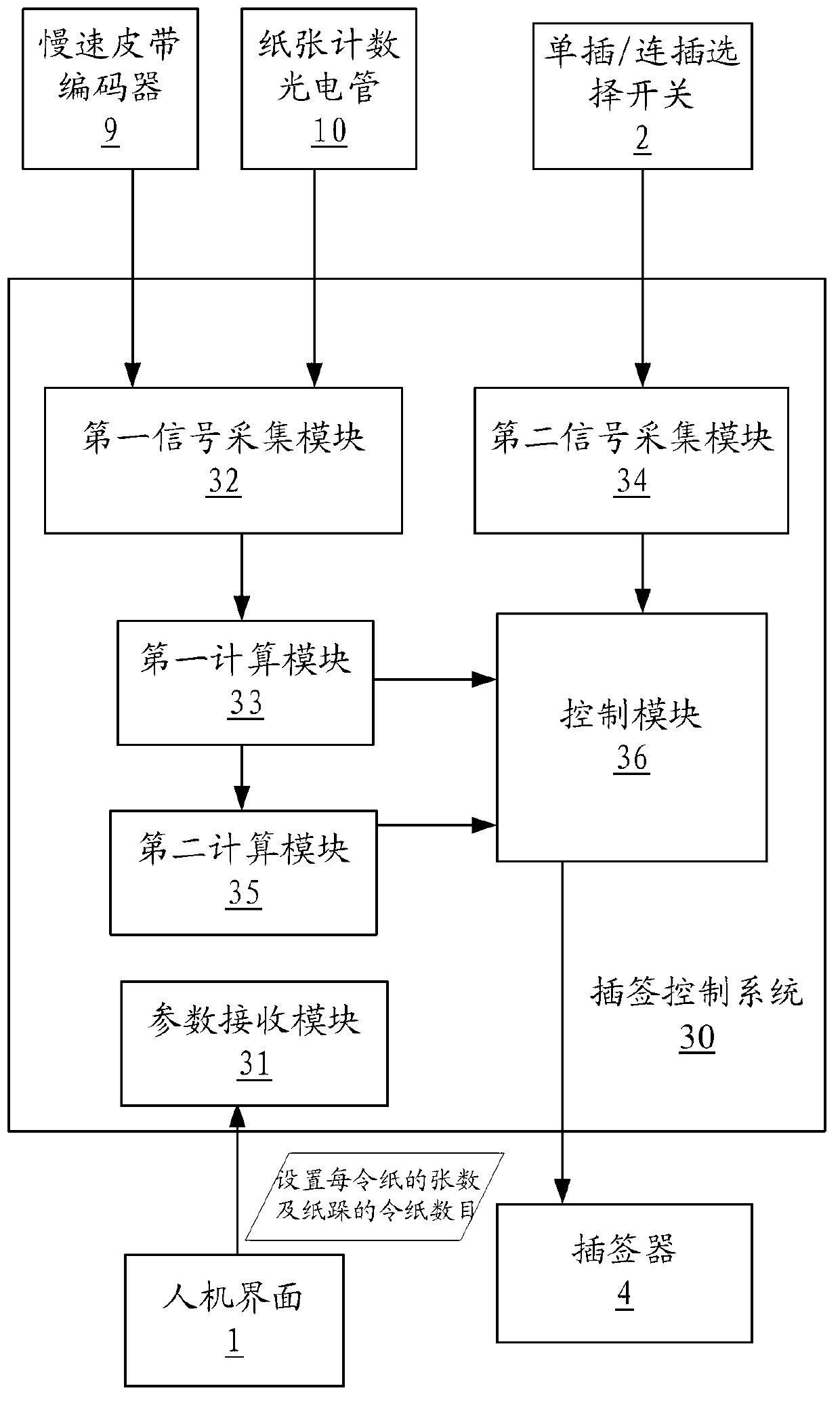

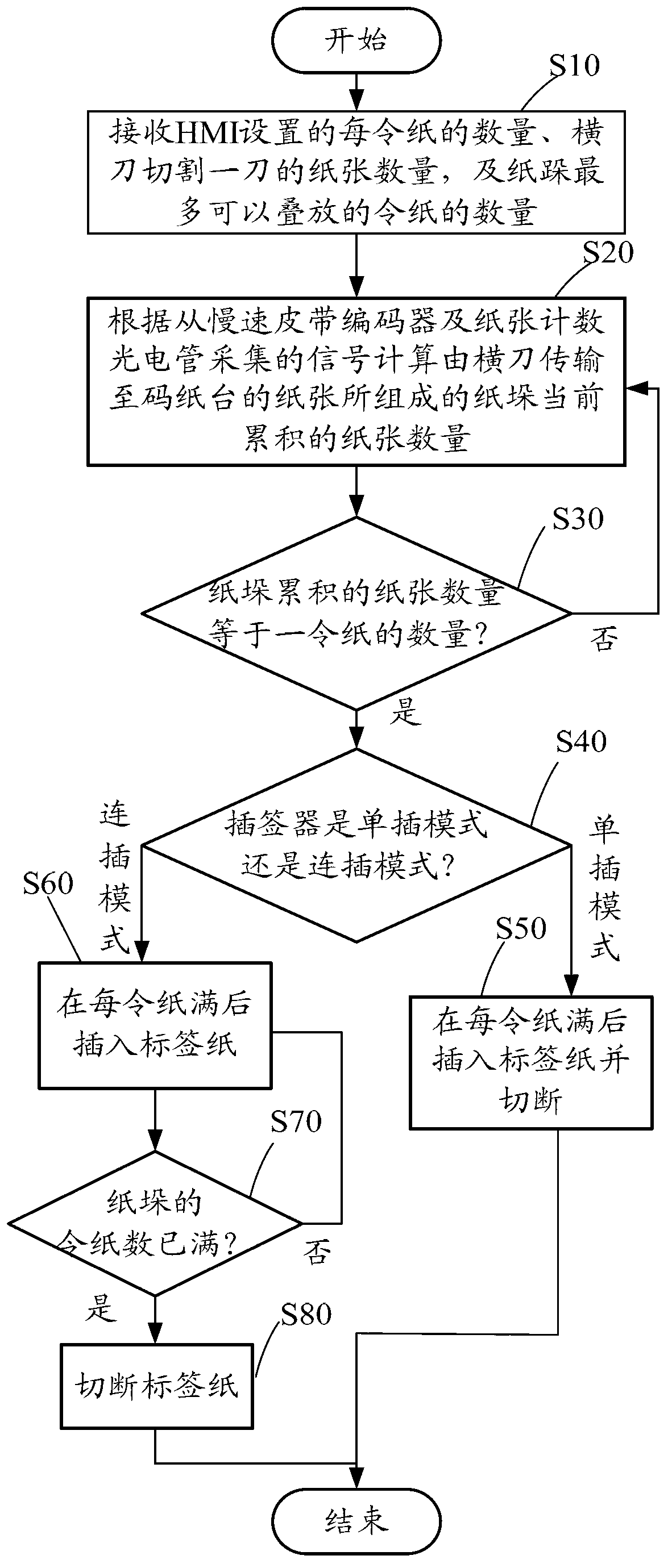

[0014] refer to figure 1 Shown is an application environment diagram of a preferred embodiment of the card insertion control system 30 of the present invention. The plug-in control system 30 is applied to a programmable logic controller (programmable logical controller, PLC) 3, and the PLC 3 is connected to a human machine interface (human machine interface, HMI) 1, a single plug / connection selection switch 2 and a plug-in through a signal cable. Signer 4. The user can set the number of papers included in each ream through HMI1 (for example, one ream = 500 sheets), and set the maximum number of reams that can be stacked in a stack (for example, 10 reams).

[0015] After the paper is cut by the horizontal knife 5, it is transported to the stacking table 8 through the fast belt 6 and the slow belt 7 to form a paper pile. A slow belt encoder 9 is installed on the slow belt 7, and a paper counting photoelectric cell 10 is installed at the junction of the fast belt 6 and the slow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com