Digital heating pipeline monitoring system

A technology for monitoring systems and heating pipelines, applied in the direction of measuring heat, thermometers and instruments using electric/magnetic elements that are directly sensitive to heat, can solve problems such as heat energy loss, time delay, and lack of inner pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

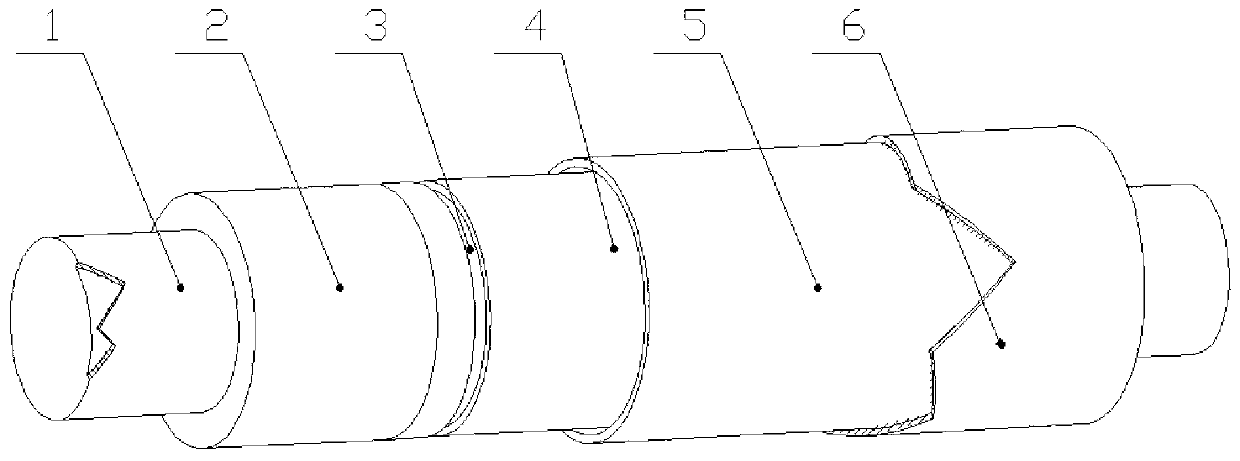

Image

Examples

Embodiment Construction

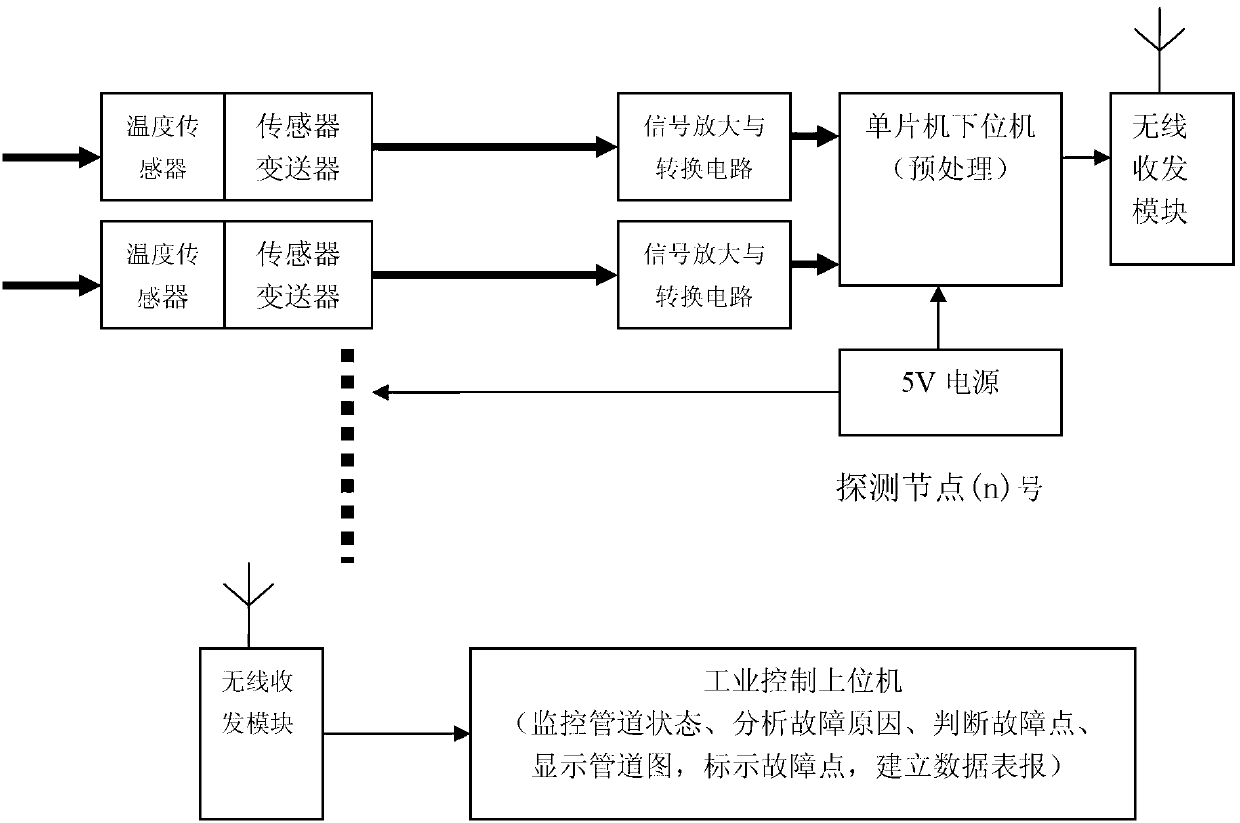

[0028] Such as figure 2 shown. The pipeline monitoring system includes an industrial control host computer and multiple detection nodes. The industrial control host computer and each detection node contain a set of wireless transceiver circuits, which have wireless data transmission and forwarding functions. A detection node is arranged every predetermined distance in the heating pipeline, and each detection node includes a plurality of temperature sensors and a single-chip microcomputer used as a lower computer. In addition, each detection node also includes a flyer transmitter and a signal amplification and conversion circuit for signal transmission and processing. Those skilled in the art can select the distance between each detection node and the distance between each sensor according to the actual situation, for example, a detection node can be set every 100 meters, a temperature sensor can be set every 10 meters, and each node contains 10-15 Temperature Sensor.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com