Measuring instrument and measuring method for micro-spherical surface profile detection

A surface profile, tiny technology, used in measuring devices, instruments, optical devices, etc., can solve problems such as low measurement accuracy and small detection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

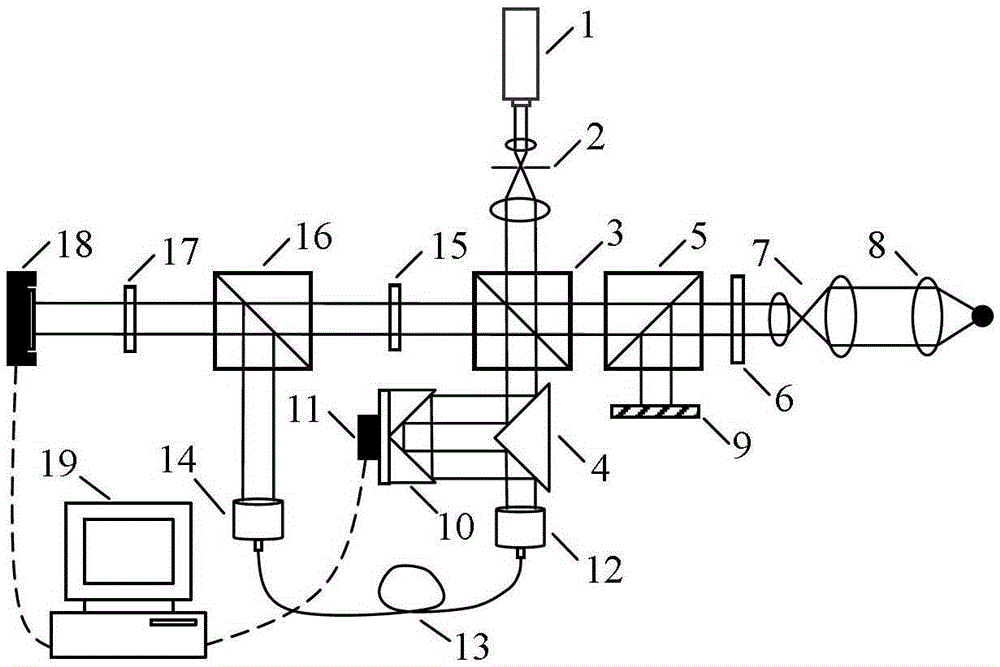

[0030] Specific implementation mode 1. Combination figure 1 Describe this specific embodiment, a kind of multiplication type phase-shifting diffraction interferometry instrument that is used for microsphere surface profile detection, it comprises short coherent laser 1, spatial filter 2, beam-splitting prism 3, right-angle reflector 4, polarization beam-splitting prism 5 , λ / 4 wave plate 6, 4f beam expander system 7, microscope objective lens 8, plane mirror 9, corner cube prism 10, phase shifter 11, fiber coupling mirror 12, single-mode fiber 13 and fiber collimating mirror 14, λ / 2 wave plate 15, polarizing beam splitting prism 16, polarizing plate 17, area array CCD 18 and computer 19, the linearly polarized laser beam emitted by short coherent laser 1 is incident on beam splitting prism 3 after being filtered and expanded by spatial filter 2, and the line The polarized laser beam is divided into the first reflected light and the first transmitted light through the beam spli...

specific Embodiment approach 2

[0039] Specific Embodiment 2. The difference between this embodiment and the double-order phase-shifting diffraction interferometer for micro-spherical surface profile detection described in the specific embodiment 1 is that the phase-shifting control signal input of the phase shifter 11 is The end is connected with the phase-shift control signal output end of the phase-shift control signal of the computer 19.

[0040] The motion accuracy of the phase shifter 12 in this embodiment is 0.1 nm, and the stroke is 2 μm. The phase shifter 12 drives the corner cube 11 to move to realize the phase shifting operation, thereby extracting more accurate phase information.

specific Embodiment approach 3

[0041] Specific Embodiment 3. The difference between this embodiment and the multiplier phase-shifting diffraction interferometry instrument for micro-spherical surface profile detection described in Embodiment 1 is that the core diameter of the single-mode optical fiber 13 is 1.5 μm-2μm.

[0042] The core of the single-mode optical fiber 14 described in this embodiment is very thin, so the single-mode optical fiber 14 itself has a good filtering effect, and at the same time, the spatial wavefront distortion can be precisely eliminated by using the bending loss characteristic of the optical fiber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com