Contact-type three-dimensional scanning measuring head

A scanning probe and contact technology, applied in the field of three-dimensional contact scanning probe, can solve the problems of Abbe error sensitivity, complex conversion circuit, low frequency response, etc., to achieve consistent dynamic characteristics, simplified mechanical structure, simple installation and debugging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

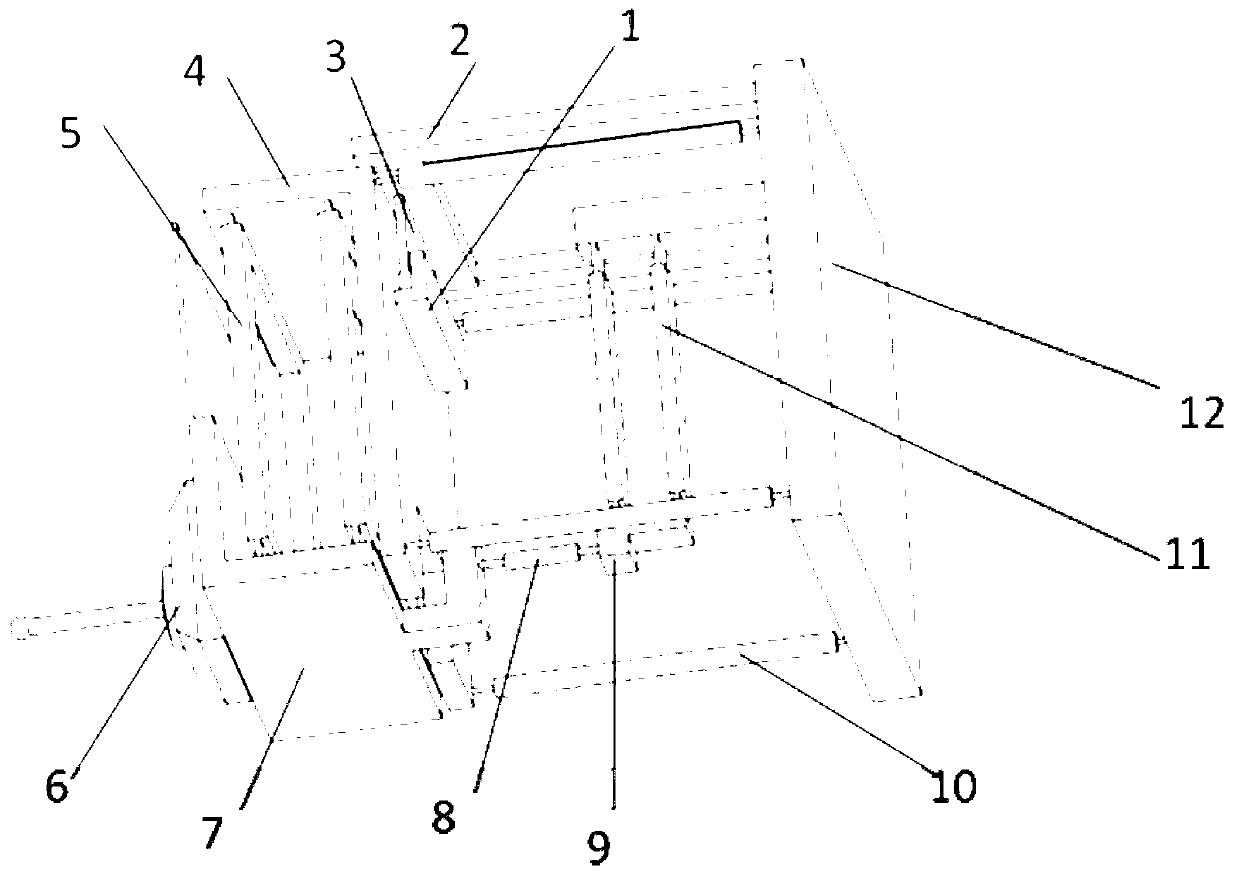

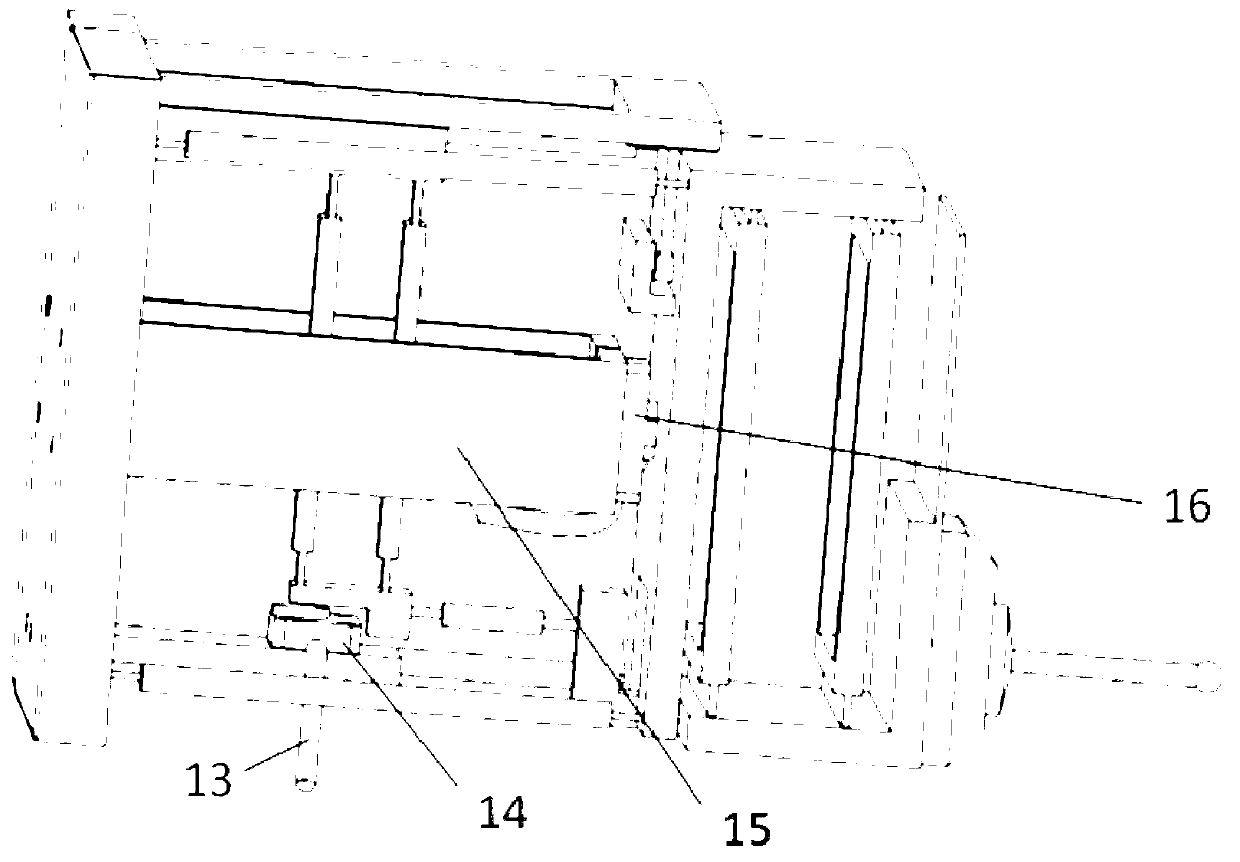

[0015] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0016] like figure 1 As shown in the present invention, a three-dimensional contact scanning probe measurement device includes a mechanical probe part and a grating signal processing part; the mechanical probe part includes a parallel reed structure and four The elastic parallelogram structure of the axial, horizontal and vertical directions of the stylus composed of double hinge rods, the elastic parallelogram structure along the axial direction of the stylus is composed of a pair of reeds A5 and two ends of the translation plate A4 respectively. It is fixedly connected with the stylus base 7, and the elastic parallelogram structure in the horizontal direction and the vertical direction is composed of four double hinge rods 10A. Parallel to each other, one end is perpendicular to one side of the bottom plate 12, and is fixedly connected with the bottom plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com