Process and device for improving utilization rate of ethylene oxide of metronidazole production raw materials

A technology of ethylene oxide and metronidazole, which is applied in the field of technology and equipment to improve the utilization rate of ethylene oxide as a raw material for the production of metronidazole, can solve the problems of low utilization rate of ethylene oxide, and is beneficial to environmental protection , good environmental benefits, and the effect of enhancing market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

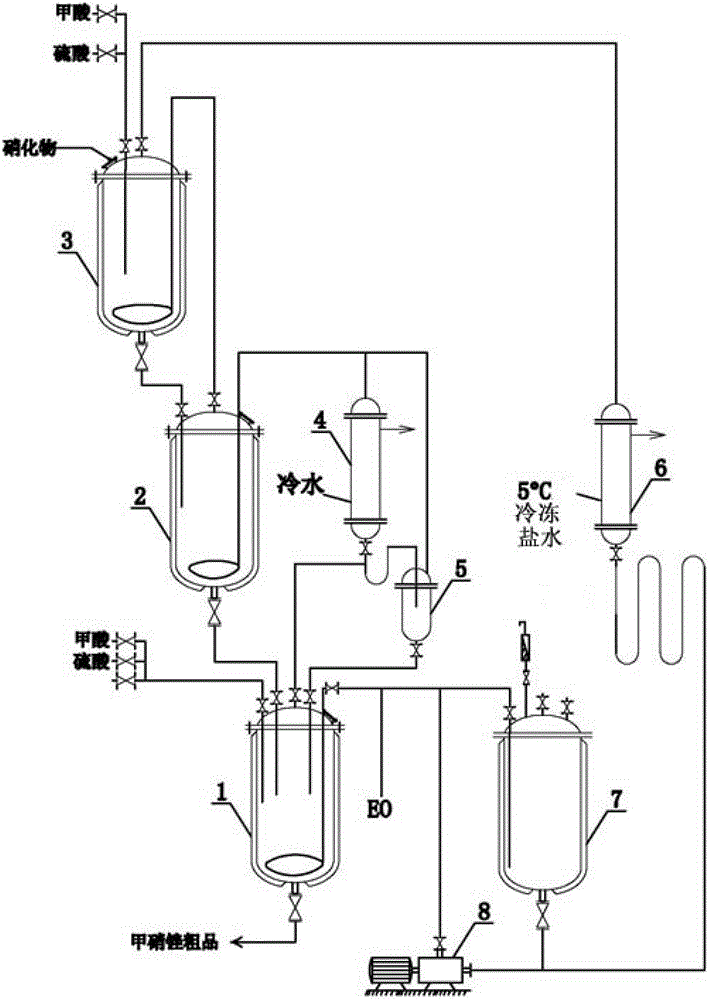

[0032] Embodiment 1: the technique of improving metronidazole production raw material oxyethane utilization rate of the present invention, it comprises the steps:

[0033] The first material is started, and the initial feeding of the three kettles is as follows: the pre-reaction kettle and the pre-dissolution kettle are respectively put into 150kg of nitrates, 80kg of formic acid and 80kg of sulfuric acid; the synthesis reactor is put into 150kg of nitrates, 105kg of formic acid and sulfuric acid 95 kg.

[0034] Start the car, feed ethylene oxide at a flow rate of 60kg / h, and feed time for 180 minutes, and control the reaction temperature of the synthesis reactor at 89-93°C. The temperature of the pre-reactor is controlled at 80±2°C; the temperature of the pre-dissolving kettle is controlled at 35±5°C. After the operation of feeding ethylene oxide is completed, the reaction is kept for 30 minutes, the synthetic reaction is completed, and the vehicle is shut down.

[0035] Re...

Embodiment 2

[0043] Embodiment 2: the technique of improving metronidazole production raw material oxyethane utilization rate of the present invention, it comprises the steps:

[0044] The first material is started, and the initial feeding of the three kettles is as follows: the pre-reaction kettle and the pre-dissolution kettle are respectively put into 150kg of nitrates, 80kg of formic acid and 80kg of sulfuric acid; the synthesis reactor is put into 150kg of nitrates, 105kg of formic acid and sulfuric acid 95 kg.

[0045] Start the car, feed ethylene oxide at a flow rate of 60kg / h, and feed time for 180 minutes, and control the reaction temperature of the synthesis reactor at 89-92°C. The temperature of the pre-reactor is controlled at 80±2°C; the temperature of the pre-dissolving kettle is controlled at 35±5°C. After the operation of feeding ethylene oxide is completed, the reaction is kept for 30 minutes, the synthetic reaction is completed, and the vehicle is shut down.

[0046] Re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com