Ultrasonic-assisted local metallizing method on surface of ceramic

A ceramic surface and metallization technology, which is applied in the field of ceramic surface metallization, can solve the problems of high equipment cost, time-consuming, complicated process, etc., and achieve the effect of extensive metal and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

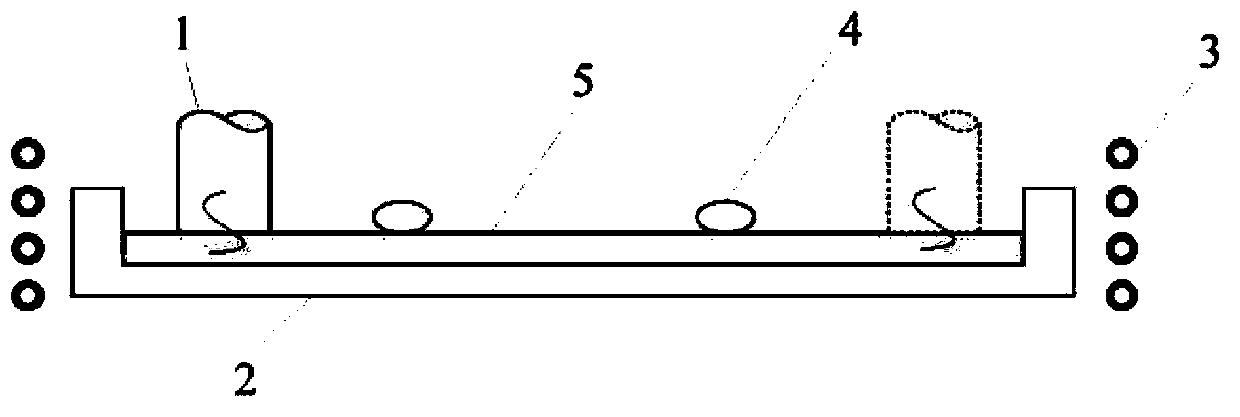

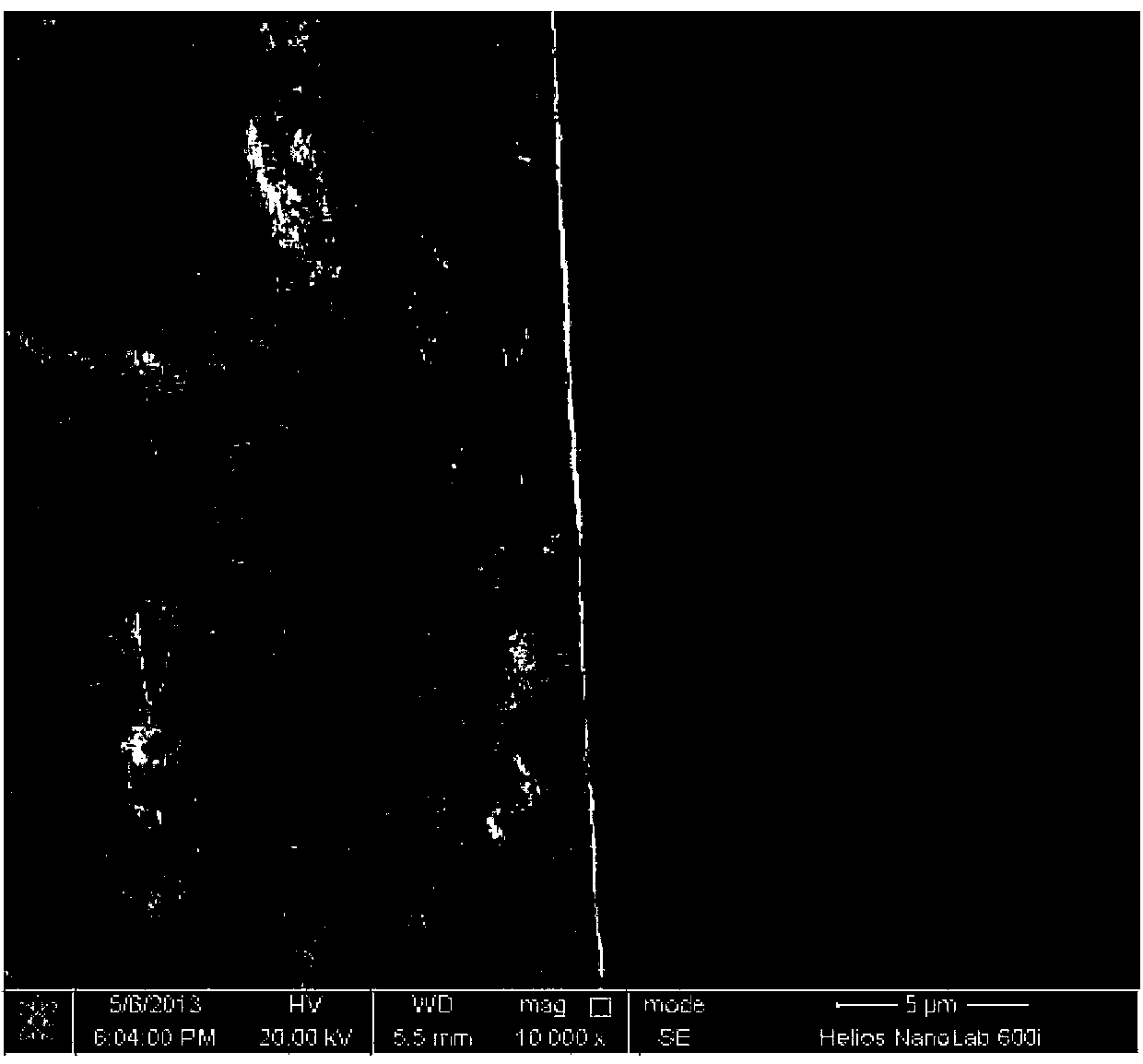

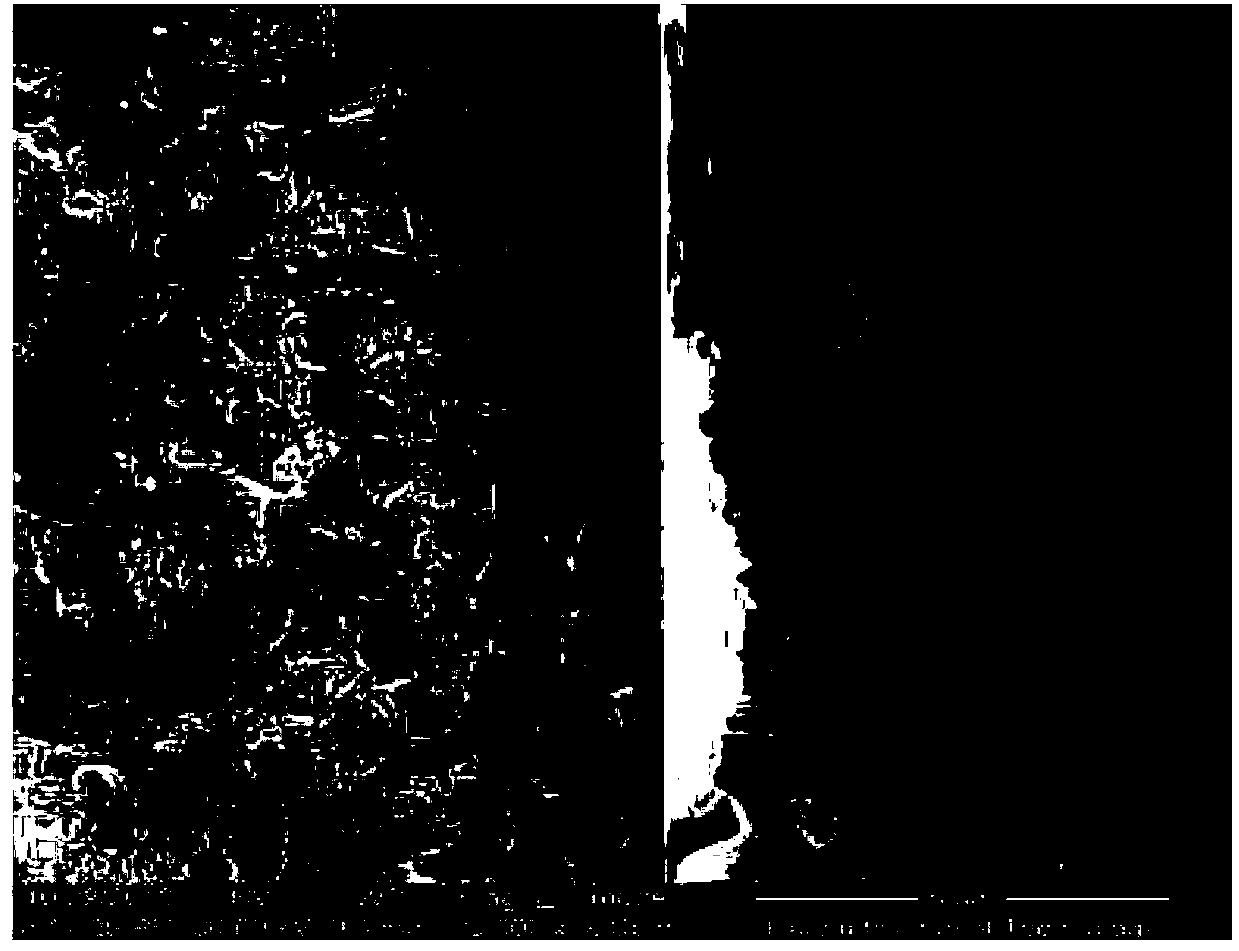

[0033] Embodiment 1: In this embodiment, a method for ultrasonically assisted local metallization of ceramic surfaces is carried out in the following steps:

[0034] 1. Ultrasonic cleaning the surface of the ceramic substrate to be metallized with deionized water for 8 minutes to 12 minutes to obtain a clean ceramic substrate to be metallized;

[0035] Two, the pre-cutting volume is the metallized raw material of V, the area of the ceramic substrate surface to be metallized that is obtained in step 1 is X, and the clean ceramic substrate surface to be metallized that is obtained in step 1 is to be treated as X. The thickness of the pre-plated metal layer in the metallization area is Y, then: V=X·Y;

[0036] 3. Put the clean ceramic substrate to be metallized in the fixture plate, and then use high-frequency induction heating or resistance heating to heat the clean ceramic substrate to be metallized, and heat the clean ceramic substrate to be metallized to 20° C. to 100° C. ...

specific Embodiment approach 2

[0044] Embodiment 2: This embodiment differs from Embodiment 1 in that: in step 3, the cleaned ceramic substrate to be metallized is heated to 30° C. to 70° C. above the melting point of the metallization raw material described in step 2. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0045] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 4, when the surface area of the cleaned ceramic substrate to be metallized is less than or equal to 9×10 4 mm 2 When , the ultrasonic action mode of the single acoustic pole is used for ultrasound. Others are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com