Quick-acting anti-slump restorer for pump concrete

A technology for pumping concrete and restoring agent, which is applied in the field of quick-acting anti-slump restoring agent for pumping concrete, can solve problems such as falling, and achieve the effects of easy availability of raw materials, quality assurance, and simple use method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

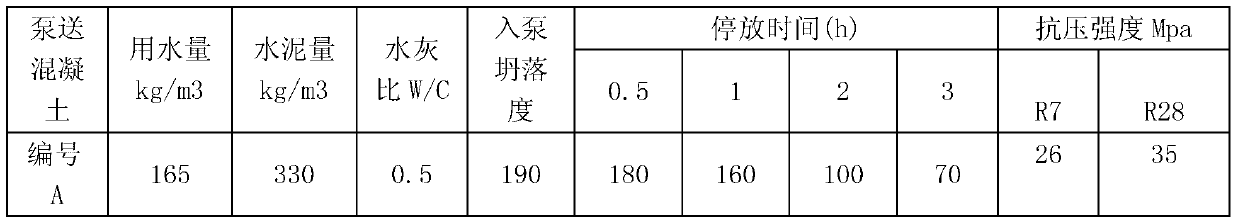

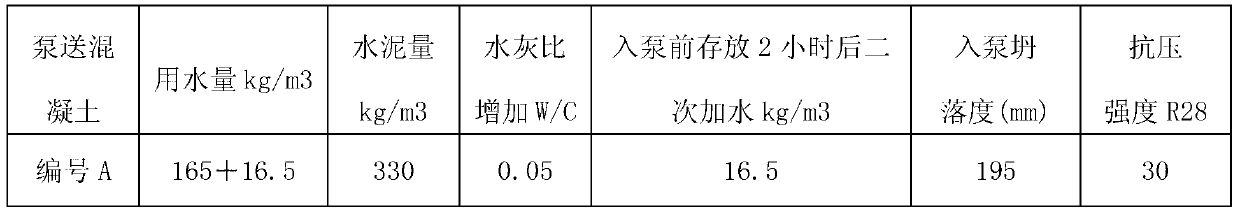

Method used

Image

Examples

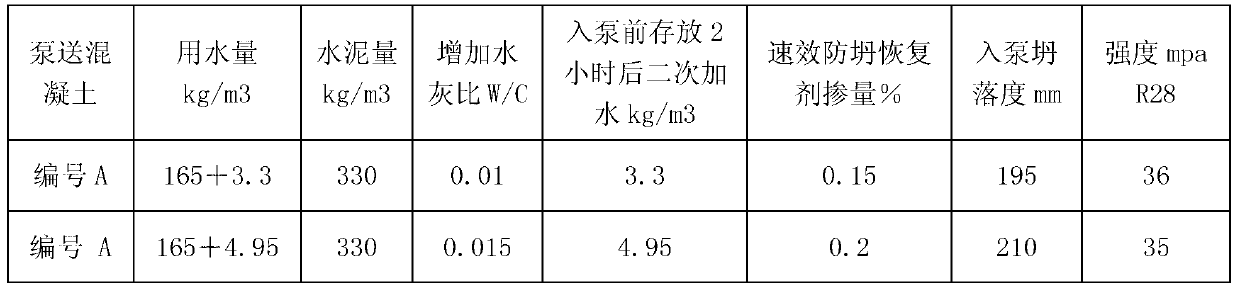

Embodiment 1

[0019] Example 1. Take 70kg of naphthalenesulfonic acid formaldehyde condensation product water reducer, 15kg of strengthening agent, and 15kg of sodium lauryl sulfate sodium dodecylbenzenesulfonate, and mix them to make a quick-acting anti-slump recovery agent for pumping concrete.

[0020] The above accelerator is composed of triethanolamine, sodium sulfate and aluminum sulfate in a weight ratio of 70:15:15.

[0021] When the pumped concrete fails to meet the slump requirements of the pumped concrete, add the above-mentioned pumped concrete quick-acting anti-slump restoration agent according to 0.15 of the cement weight in the pumped concrete, and add the above-mentioned pumped concrete quick-acting anti-slump recovery agent according to the weight of the cement in the pumped concrete , add water to increase the water-cement ratio by 0.01, and stir evenly.

Embodiment 2

[0022] Example 2. Take 60kg of naphthalenesulfonic acid formaldehyde condensate superplasticizer, 20kg of strengthening agent, and 20kg of sodium lauryl sulfate sodium dodecylbenzenesulfonate, and mix them to make a fast-acting anti-slump restoration agent for pumping concrete.

[0023] The above accelerator is composed of triethanolamine, sodium sulfate and aluminum sulfate in a weight ratio of 70:15:15.

[0024] When the pumped concrete fails to meet the slump requirements of the pumped concrete, add the above-mentioned pumped concrete quick-acting anti-slump recovery agent according to 0.2% of the weight of the cement in the pumped concrete, and follow the cement in the pumped concrete Weight, add water to increase the water-cement ratio of 0.015, and stir evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com