Tool bit of glass cutter

A cutting machine and cutter head technology, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of easily damaged cutter heads, easily damaged cutter grains, and insufficient flexibility, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The content of the present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited thereto.

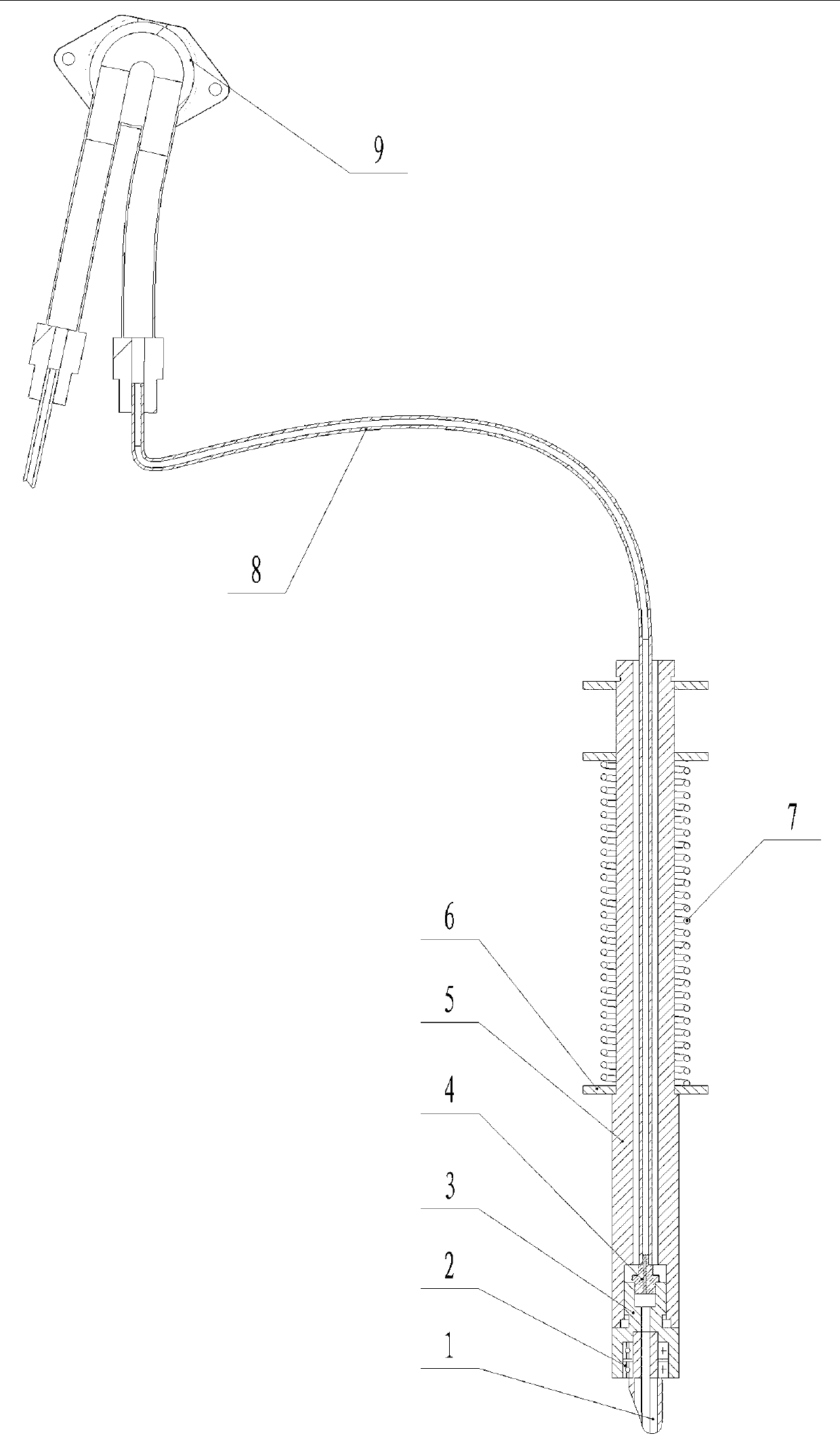

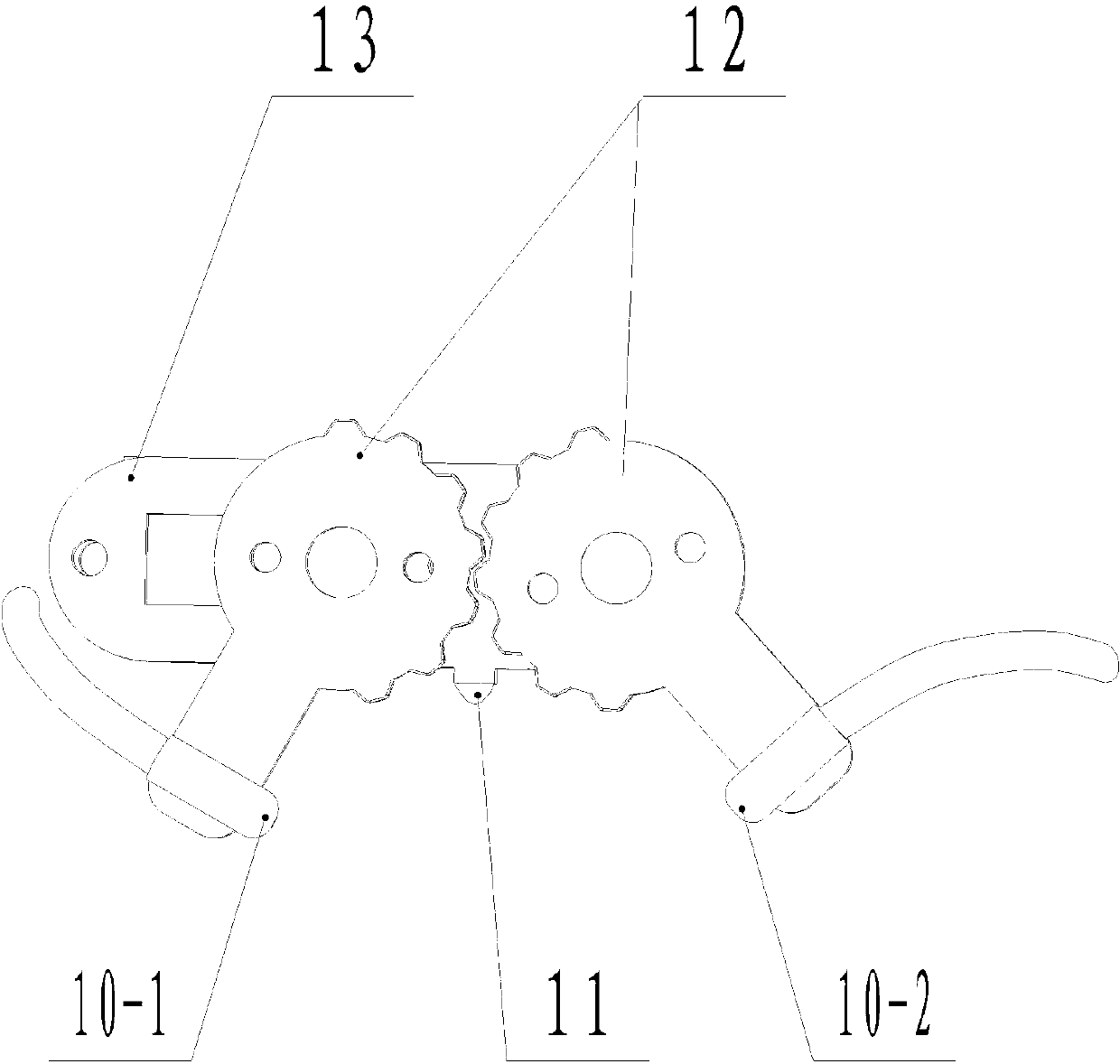

[0017] refer to figure 1 , a cutter head of a glass cutting machine, comprising a knife grain 1, a knife head connection 3, a knife rod 5, an oil delivery pipe 8, and an oil pipe joint 4, the knife head connection 3 is arranged on the front end of the knife rod 5, and the knife grain 1 is arranged on the knife head connection 3, the oil pipe joint 4 is arranged above the knife grain 1 in the cutter bar 5, communicates with the oil delivery pipe 8, and also includes

[0018] Bearing 2, knife grain 1 is rotatably connected with the front head of the knife through bearing 2; bearing 2 is two, and the two bearings are stacked up and down to ensure that knife grain 1 can rotate 360° flexibly; bearing 2 is a model of The 624Z bearing has an outer diameter of 13mm and an inner diameter of 5mm. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com