Accompanying tracking system for robot

A tracking system and robot technology are applied in the field of devices for robots to pick and place spare tires on an automobile production line. , Save material consumption, improve the effect of production tact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to better understand the technical solution of the present invention, the following will be described in detail through specific examples:

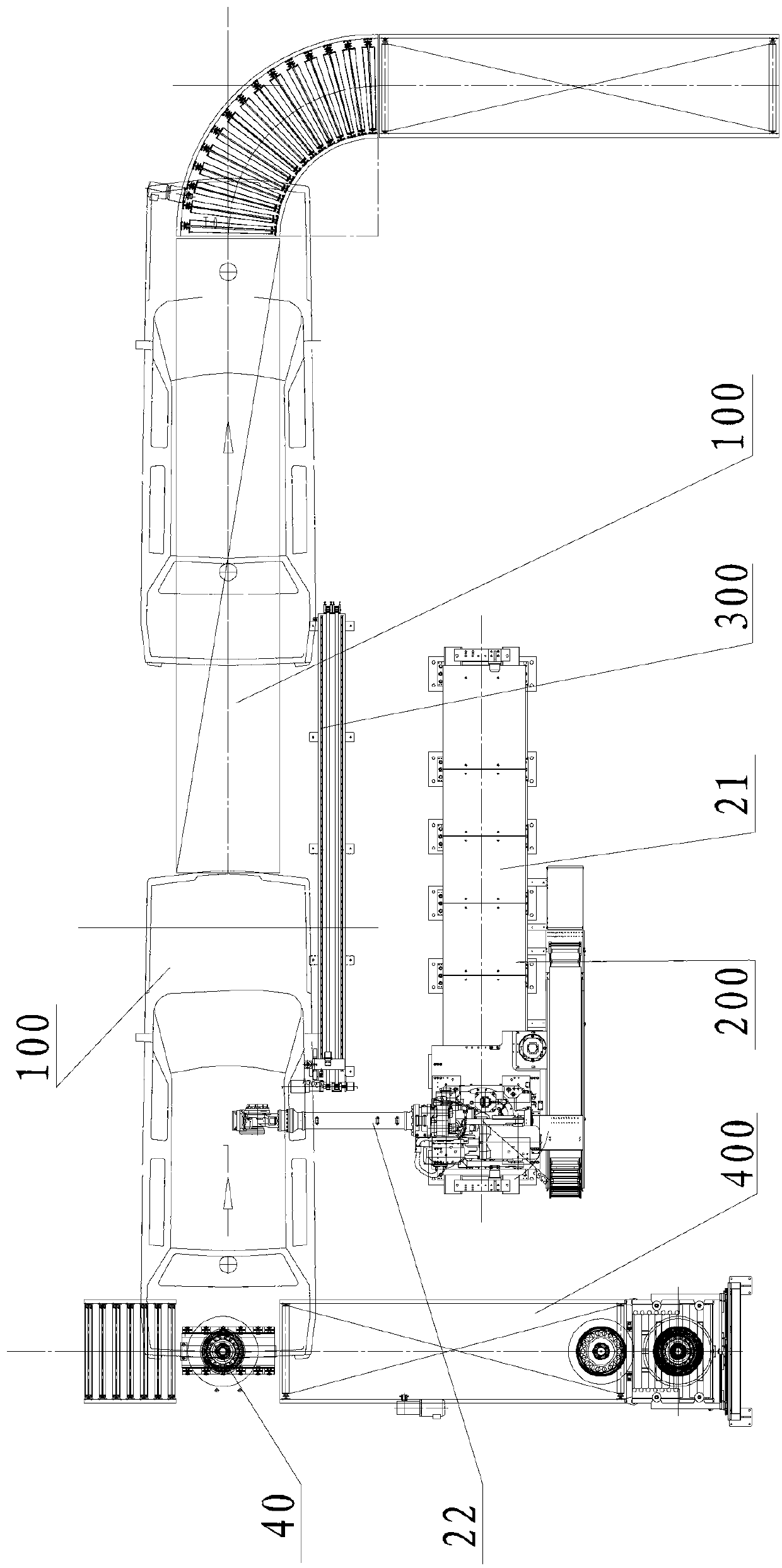

[0025] see Figure 1 to Figure 6 , the accompanying tracking system for robots of the present invention includes a production line 100 , a robot device 200 and an off-line accompanying device 300 .

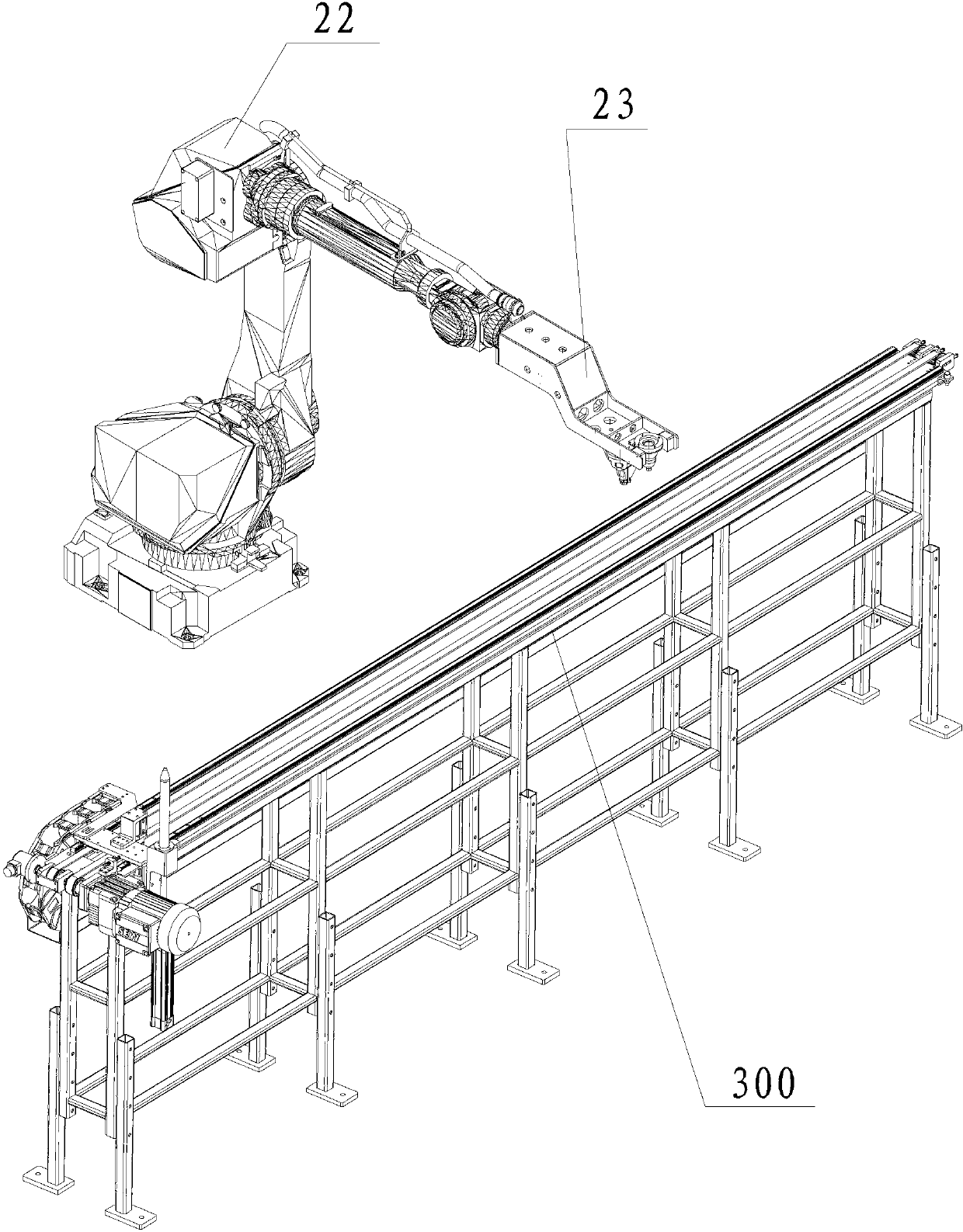

[0026] The robot device 200 includes a robot traveling mechanism 21 installed beside the production line 100 , a robot 22 installed on the robot traveling mechanism 21 , and a gripper 23 installed on the robot 22 .

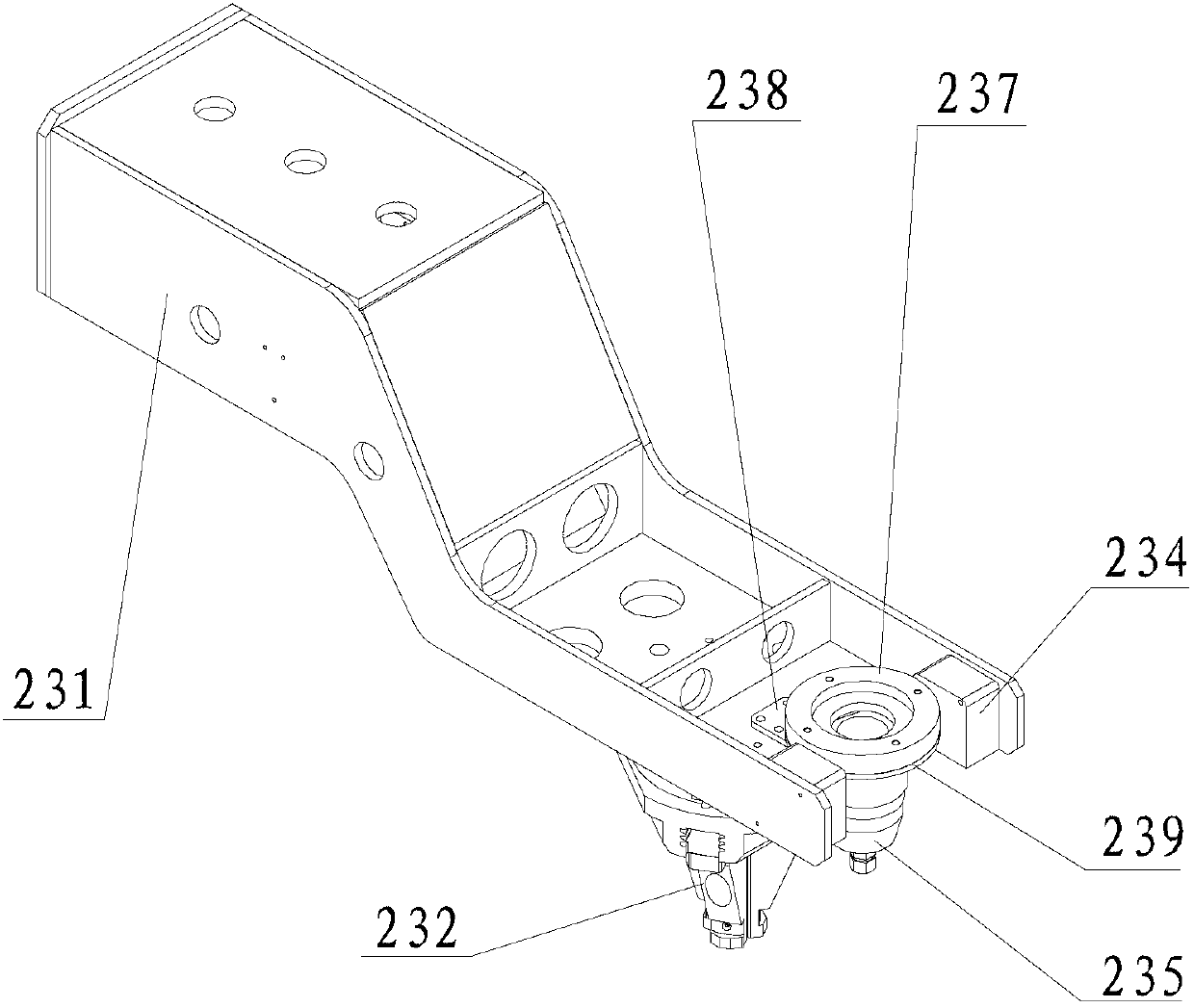

[0027] Hand 23 (see image 3 and Figure 4 ) includes a base 231, a grasping body 232, a pair of laser sensors 234, a 2D camera 235 and a camera light source 237, wherein the base 231 is in a zigzag shape and its tail end is connected to the arm end of the robot 22; the grasping body 232 passes through One hand grasps the cylinder 233 and is installed on the front portion of the base 231; a pair of laser sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com