Apparatus and method for confinement and suppression of photoinduced plasma in high-power laser deep penetration welding

A laser deep penetration welding, high-power technology, used in laser welding equipment, welding equipment, manufacturing tools, etc., can solve problems such as difficult implementation, limitations, and lack of detailed introduction, and achieve suppression of diffusion expansion and good weld formation. , The effect of stable welding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

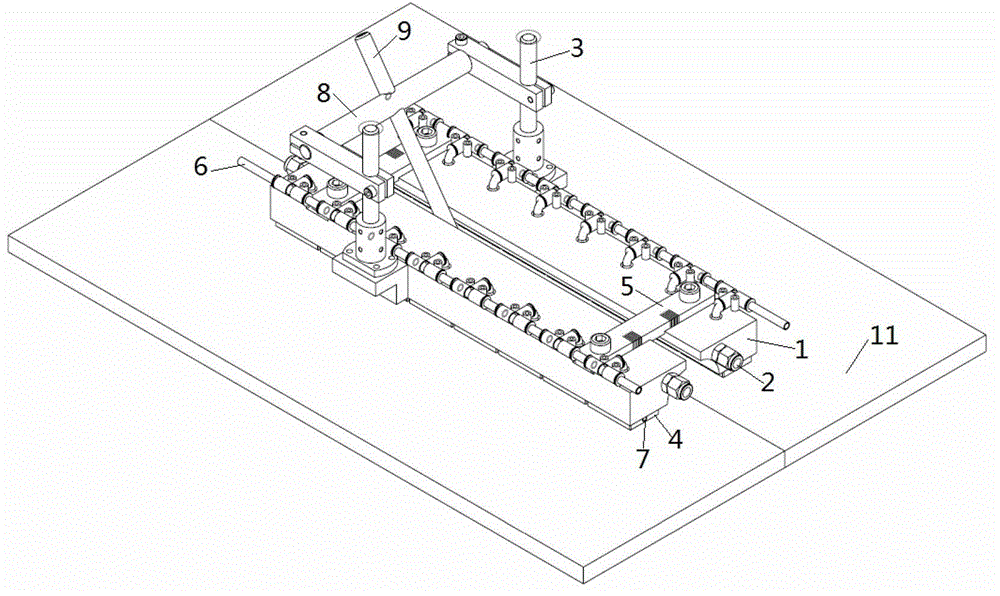

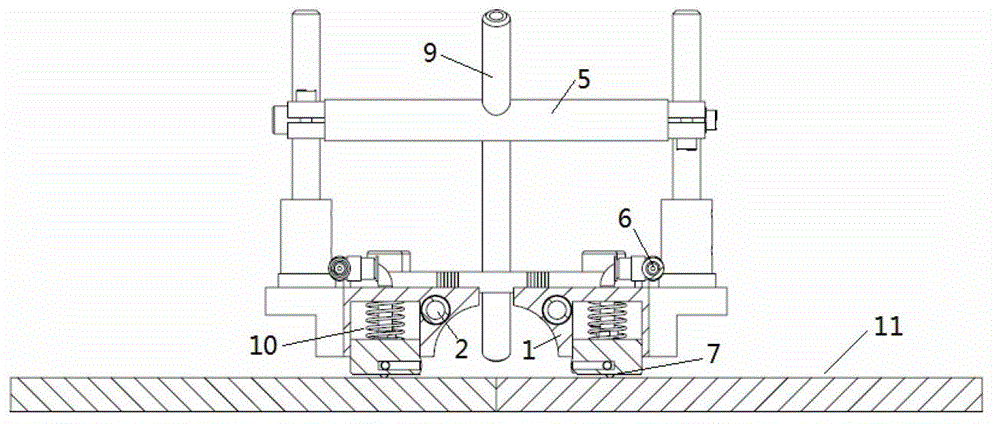

[0028] like figure 1 As shown, this embodiment includes: cooling copper block 1, cooling water interface 2, height adjustment rod 3, floating air curtain 4, lateral distance adjustment rod 5, air curtain air pipe interface 6, moving ball 7, casing 8, side blowing air pipe 9 , spring 10, workpiece 11.

[0029] The cooling copper block 1 is divided into axisymmetric left and right parts, which are respectively placed on the left and right sides of the welding seam along the welding seam direction of the workpiece 11. The surfaces of the left and right parts of the cooling copper block 1 facing the welding seam are both arranged in an arc shape. Cooling copper block height 15mm. The front end of the left half of the cooling copper block 1 is connected to the cooling water interface 2, and the rear end is also connected to the cooling water interface. The cooling water flows through the left half of the cooling copper block 1, and the circulation of cooling water is realized thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com