Casting type 3D printer

A 3D printer and 3D technology, applied in the field of 3D printers, can solve the problems of slow processing speed and narrow application range, and achieve the effect of fast printing speed and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

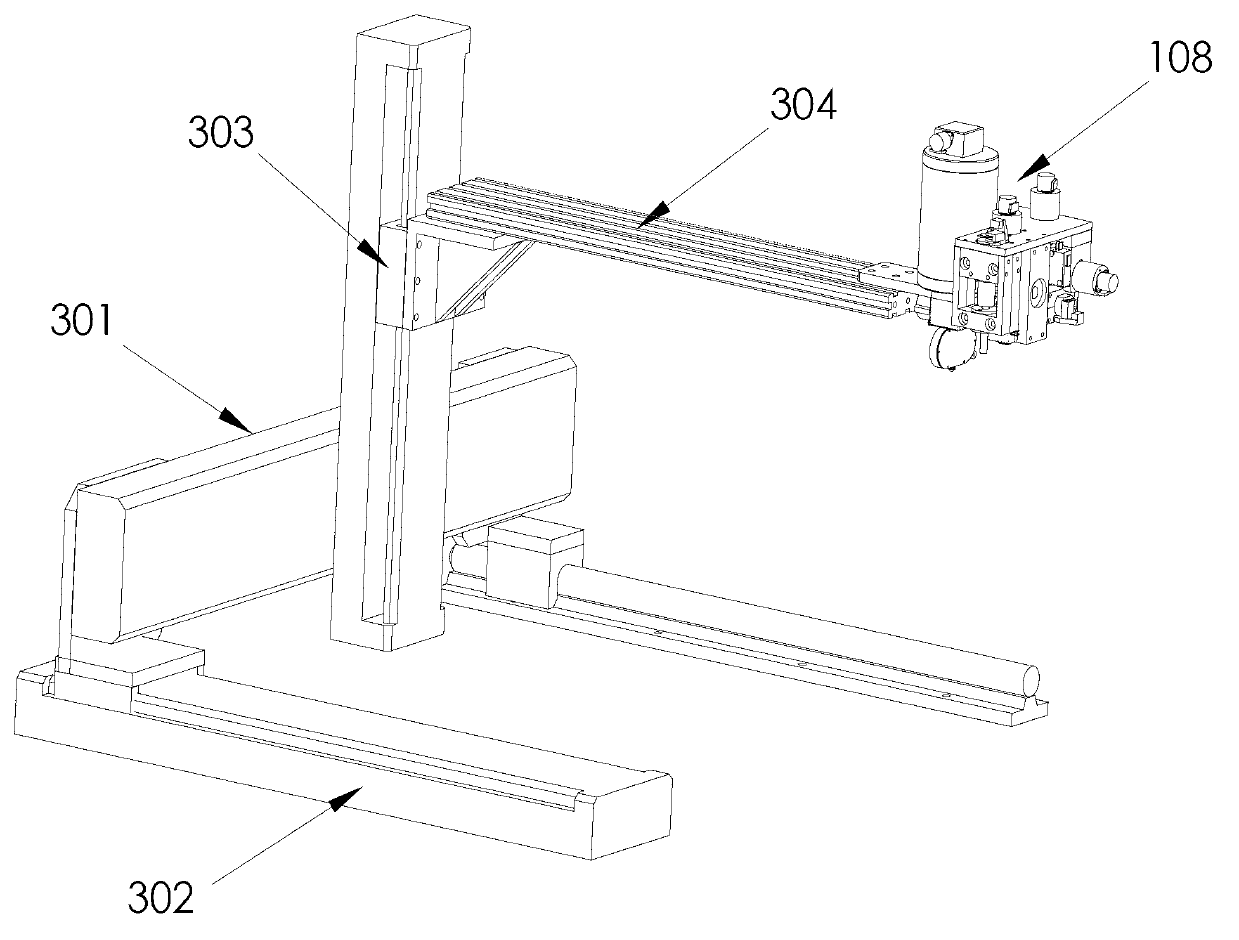

[0029] This embodiment provides a casting type 3D printer, the casting type 3D printer such as image 3 , Figure 4 shown, where, image 3 It is a three-axis linkage 3D printer, Figure 4 It is the Z-axis control in the vertical direction + the polar coordinate control in the plane. like image 3 As shown, the 3D transmission mechanism of the casting 3D printer includes: an X-axis transmission mechanism 301, a Y-axis transmission mechanism 302, a Z-axis transmission mechanism 303 and a Z-axis extension rod 304;

[0030] The X-axis transmission mechanism 301 is fixed on the Y-axis transmission mechanism 302, and the X-axis transmission mechanism 301 can move along the Y-axis direction on the Y-axis transmission mechanism 302;

[0031] The Z-axis transmission mechanism 303 is fixed on the X-axis transmission mechanism, and the Z-axis transmission mechanism 303 can move along the X-axis direction on the X-axis transmission mechanism 301;

[0032] One end of the Z-axis extens...

Embodiment 2

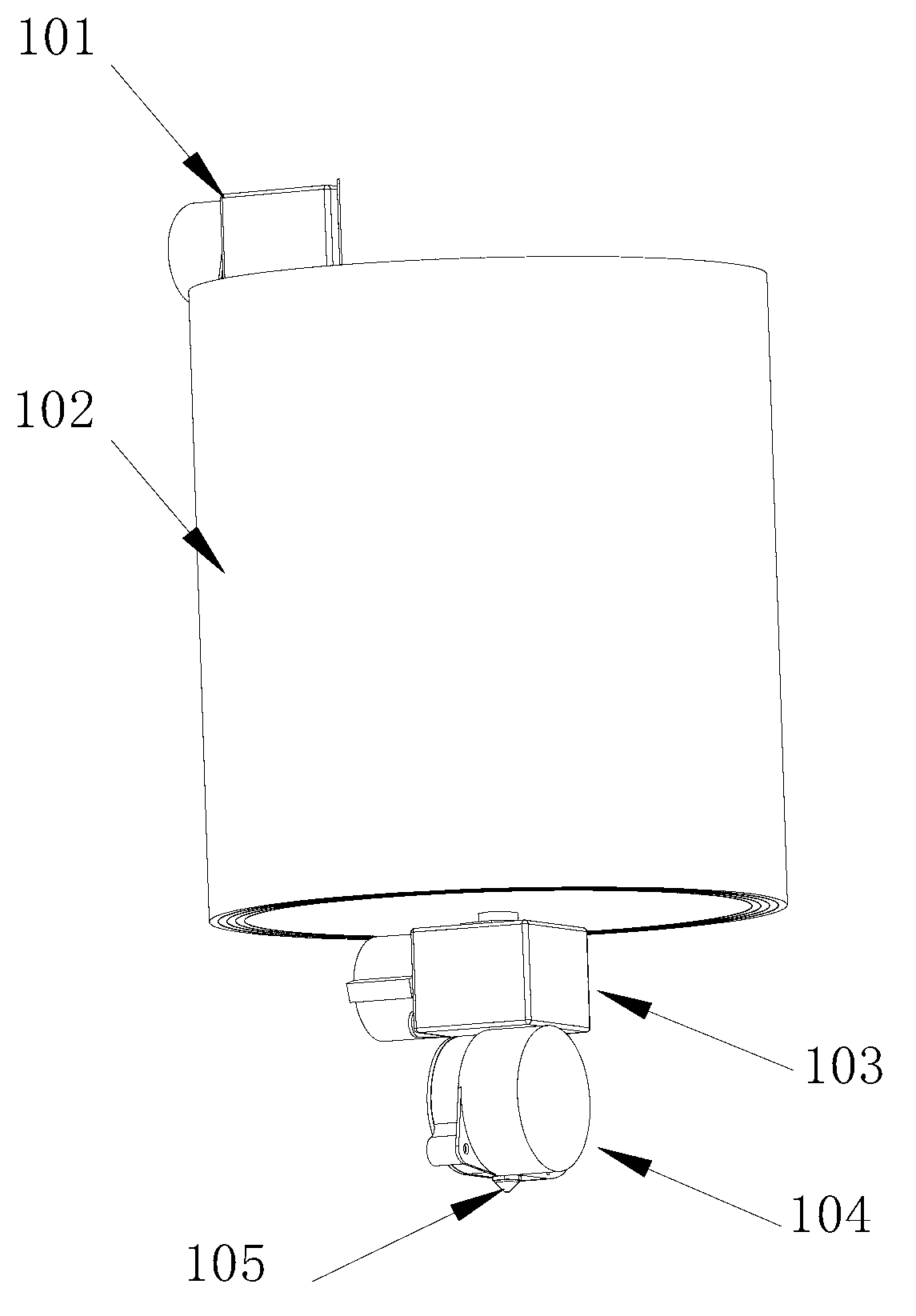

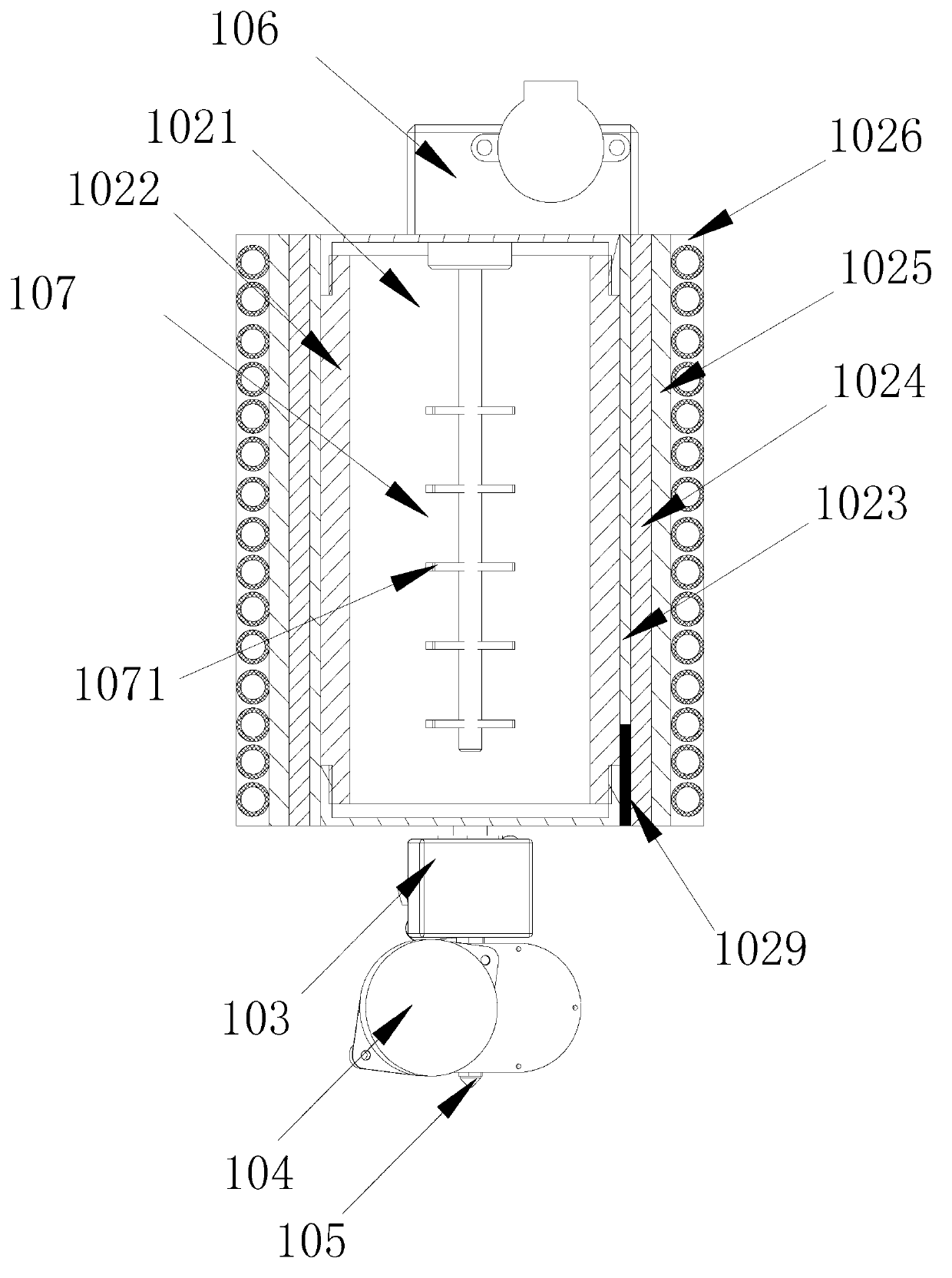

[0047] This embodiment provides a plastic melting furnace, the plastic melting furnace such as figure 2 As shown, it includes: a feeding device 101, a furnace body 102, an electric valve 103, a quantitative output pump 104 and a nozzle 105;

[0048]The furnace body 102 is, from inside to outside, a cavity 1021, a main body layer 1022, an insulating and heat-conducting layer 1023, a heating layer 1024, and an insulating and heat-insulating layer 1025; the cavity 1021 may specifically be a space for storing raw materials.

[0049] The insulating layer 1025 is used to prevent the heating layer from being directly exposed in the air, which will cause some heat to be dissipated into the air. In addition, the heating layer exposed in the air may also easily burn the user. The purpose of insulation is to prevent leakage.

[0050] The feeding device 101 is arranged on the top of the furnace body 102, and the feeding device 101 communicates with the cavity 1021;

[0051] The electri...

Embodiment 3

[0058] This embodiment provides the printing method of the casting type 3D printer shown in the first embodiment. The method includes: first, after the system of the 3D printer is powered on, according to the position of the limit switch, the entire system is returned to the origin position of the system control. Secondly, the system controls the metal or plastic melting furnace according to the materials used, and when it meets the working requirements, it enters the printing state. Then, the system inputs the outline of the 3D graphics to be printed, and prints the outline of one layer of the 3D graphics with a relatively small flow. Within the range enclosed by the outline of the layer, the system pours the entire layer with a large flow rate, and the entire layer of the 3D part is poured. After the pouring of one layer is completed, the system controls the temperature of the upper surface of the layer to a temperature suitable for secondary processing through thermal field...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com