Cold-rolled sheet shape signal online mode recognition method

A pattern recognition, cold-rolled sheet technology, applied in metal rolling, metal rolling, manufacturing tools, etc., can solve problems such as unsatisfactory accuracy and real-time performance, complex identification model structure, and long network training time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with specific examples and accompanying drawings.

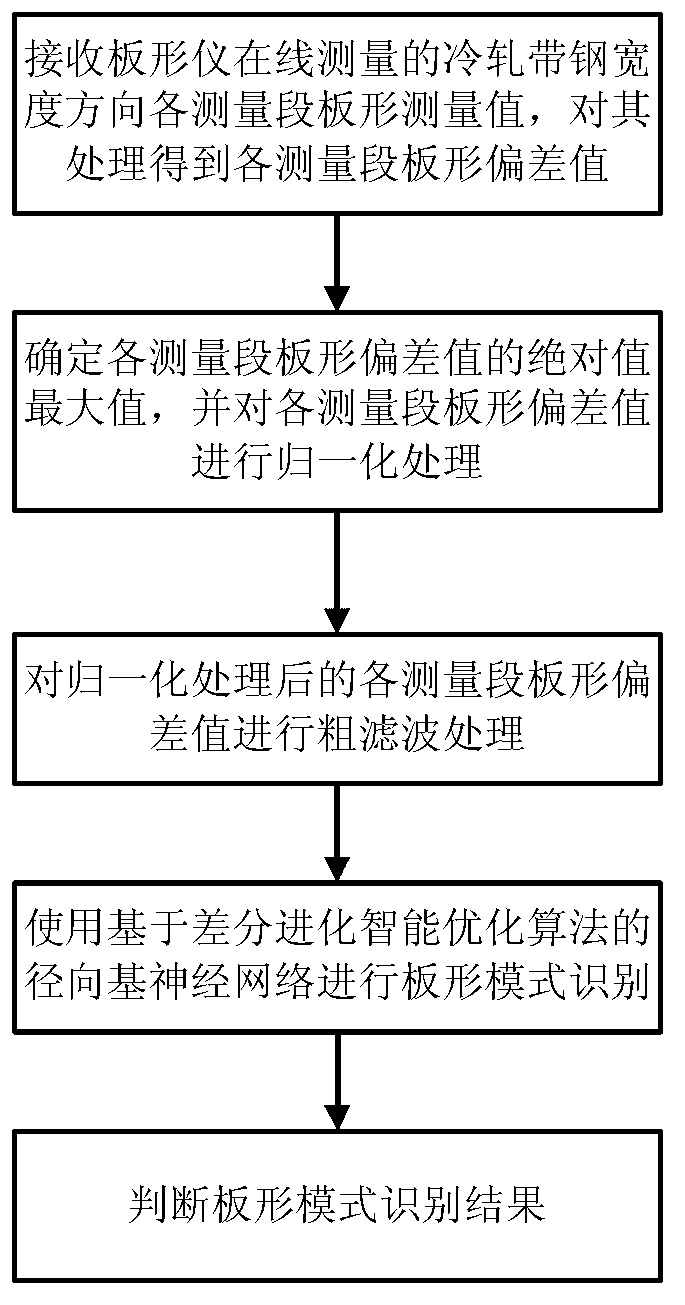

[0054] figure 1 It is a flowchart of an embodiment of the present invention, and it includes the following steps:

[0055] 1) Receive the shape measurement value of each measurement section in the width direction of the cold-rolled strip measured by the shapemeter on-line, and compare it with the corresponding target shape distribution value set to obtain the shape deviation value of each measurement section; The number is m, and the plate shape measurement value of the i-th measurement section is F i , the target shape distribution value of the i-th measurement segment is T i , the shape deviation value of the i-th measurement section is ΔF i ;

[0056] 2) Determine ΔF i The absolute value of the maximum value: ΔF max =max|ΔF i |, and normalize the shape deviation value of each measurement section, the shape deviation value Δf of the i-th meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com