Pet food sterilization and press molding process

A technology of pressing and molding pet food, which is applied in the field of pet food production technology, can solve the problems of destroying the taste of pet food, low pressing efficiency, waste of energy, etc., and achieves the effects of convenient unloading, high pressing efficiency, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

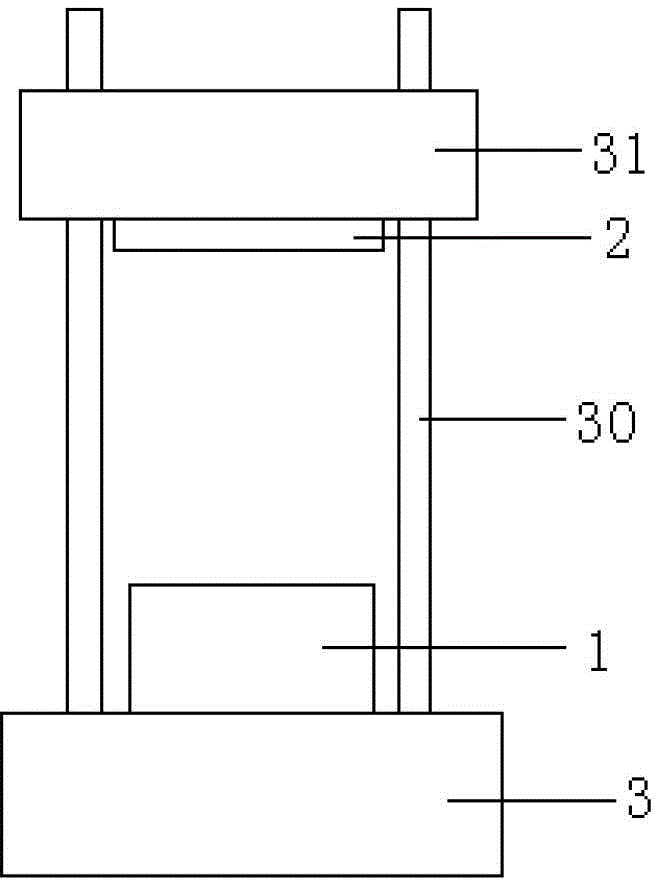

[0025] Figure 1 to Figure 7 The specific structure of the press machine for making pet food is shown, including a base 3, on which a lower mold 1 is arranged, and four uprights 30 are vertically arranged on the base, and these four uprights are distributed in a rectangular shape, so An elevating platform 31 is slidably arranged on the column, and an upper mold 2 is arranged on the lower part of the elevating platform.

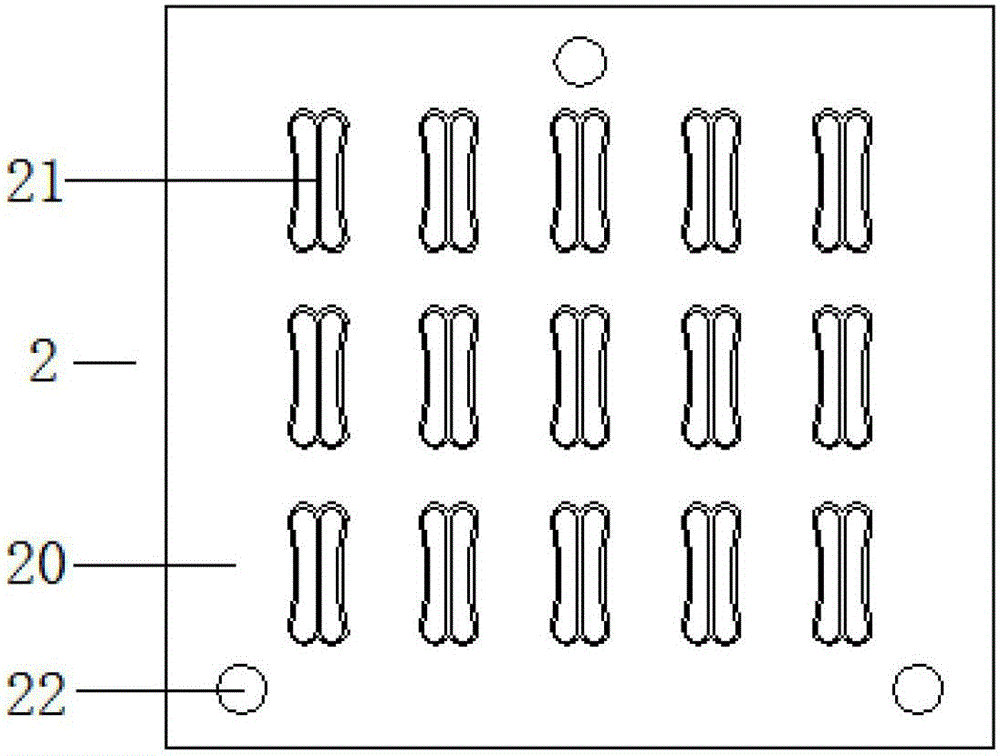

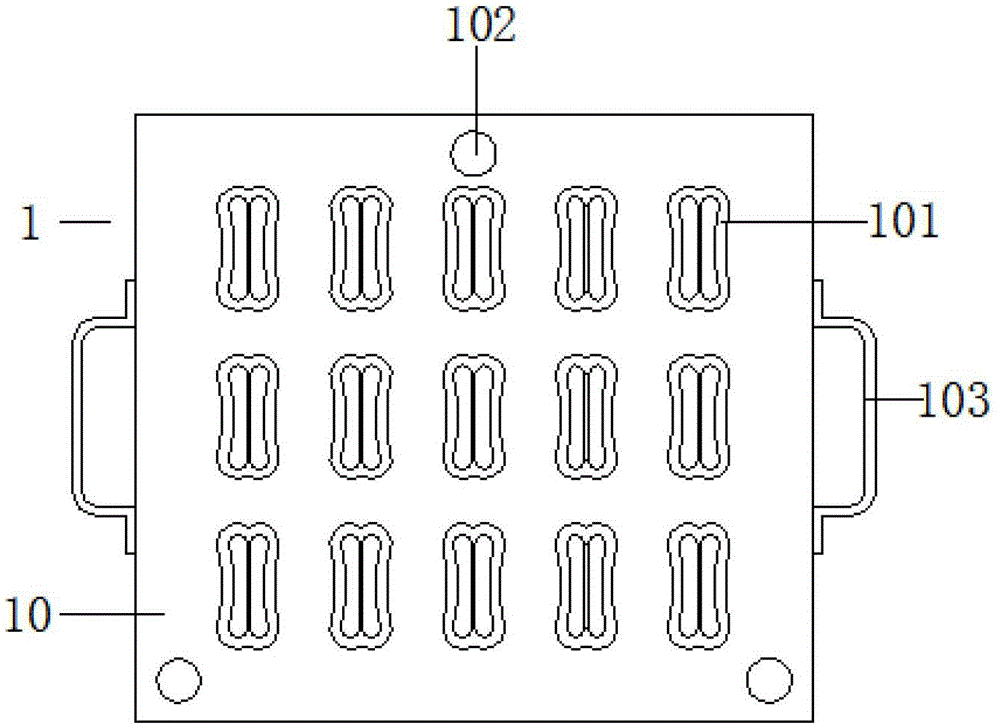

[0026] The upper mold includes an upper template 20 and an upper punch 21 arranged in a rectangular array on the bottom surface of the upper template, and the lower mold includes a first lower template 10 and a second lower template 11 fixed below the first lower template, The third lower template 12 is provided below the second lower template, the first lower template is provided with a lower die groove 101 corresponding to the upper punch, and the third lower template is provided with a lower punch corresponding to the upper punch. The lower template is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com