Synthetic system for killing soil root nematode by heat injection in root position

An integrated system and root nematode technology, applied in the field of integrated systems, can solve the problems of soil quality impact, large engineering volume, soil movement, etc., and achieve the effect of improving soil quality, good effect and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

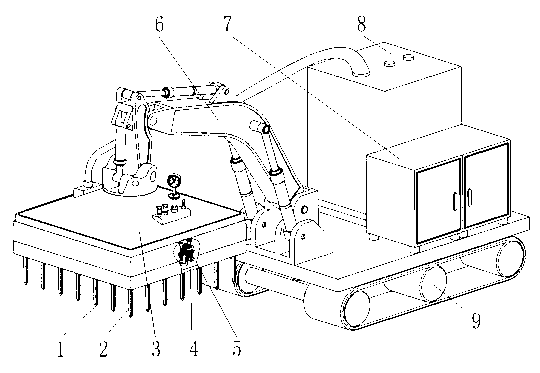

[0031] Such as figure 1 As shown, the in-situ heat injection control soil root nematode comprehensive system of the present invention mainly includes a carrier 9 , a lifting rocker 6 , a controller 7 , a steam generator 8 , a steam distribution cabin 3 , a heat injection mechanism and a support plate 4 . Lifting rocker arm 6, controller 7 and steam generator 8 are all installed on the carrier 9. The steam distribution cabin 3 is connected on the rocker arm 6 and connected with the steam generator 8 . The heat injection mechanism is connected between the steam distribution cabin 3 and the support plate 4 , and the steam distribution cabin 3 and the support plate 4 are connected by a spring 5 . The rocker arm 6 controls the lifting of the steam distribution cabin 3 , and the steam generator 8 provides steam for the steam distribution cabin 3 . The controller 7 adopts a programmable controller. Lifting rocker arm 6 can adopt hydraulic lifting rocker arm or electric lifting roc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com