Transport device

A technology of transportation device and guide rail, applied in transportation and packaging, underground transportation, track, etc., can solve the problem of unavoidable high wear of gears, and achieve the effect of reducing quantity, improving traction and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

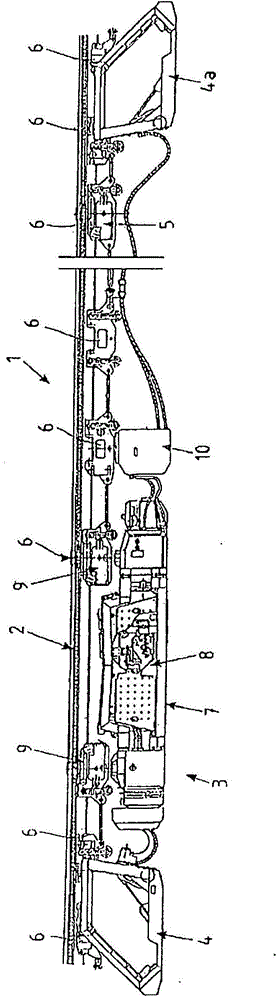

[0052] FIG. 1 shows a transport device 1 known from the prior art (DE 42 20 527 A1), which comprises an I-shaped guide rail 2 and a suspension movable on the guide rail 2 in the form of a monorail suspension rail. Transport trains for underground mining 3.

[0053] The transport train 3 has a driver's cab 4 , 4 a at both ends and a transport carriage 5 , not shown in detail, between the driver's cabs 4 , 4 a. The driver's cab 4 , 4 a and the transport carriage 5 can be moved along the guide rail 2 by means of the undercarriage 6 .

[0054] Connected to the driver's cab 4 is a tractor 7 which is provided with a diesel-hydraulic drive 8 . The tractor 7 has two drive units 9 . Following the tractor 7 is a cooling device 10 suspended on the guide rail 2 via the undercarriage 6 .

[0055] A toothed rack (not shown in detail) is provided in sections above the guide rail 2 , which meshes with a gear wheel of the drive unit 9 when the friction wheel, which is also present, is lifte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com