Protective cover with curved surface and touch panel adopting same

A touch panel and protective cover technology, applied in the input/output process of data processing, instruments, electrical digital data processing, etc., can solve the problems of low surface utilization rate of the protective cover, unfavorable touch panel miniaturization, etc., and improve surface utilization The effect of increasing the rate and increasing the surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

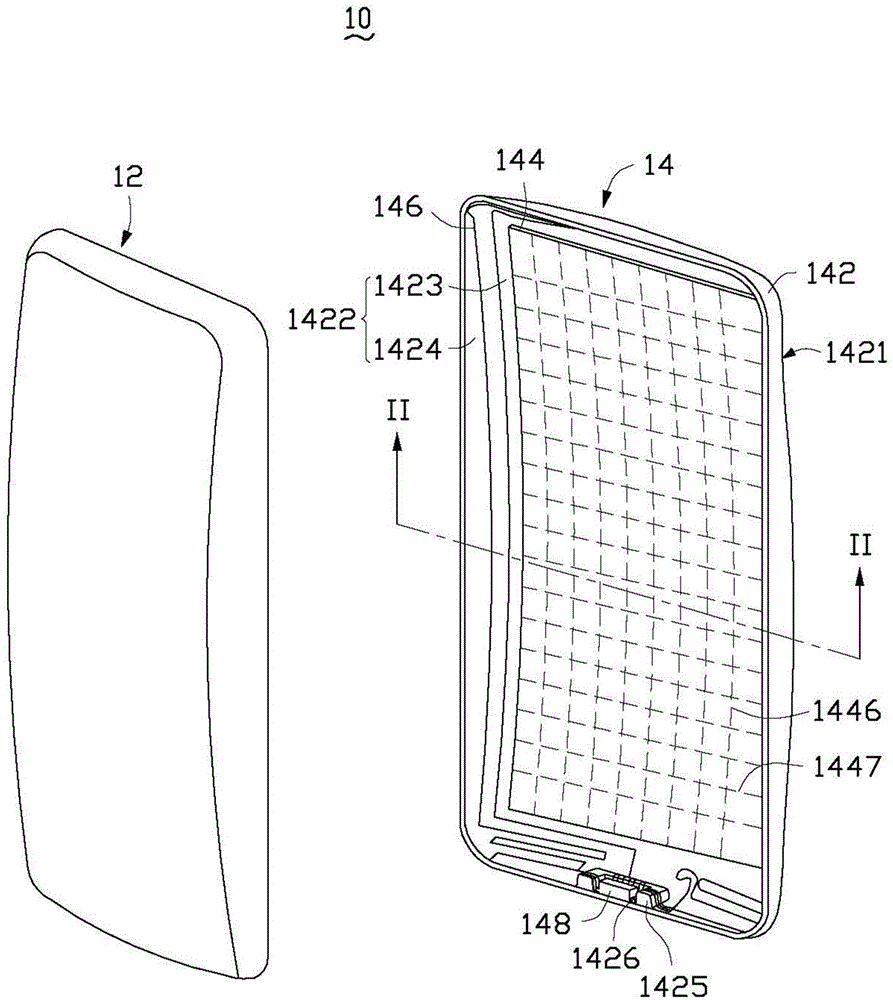

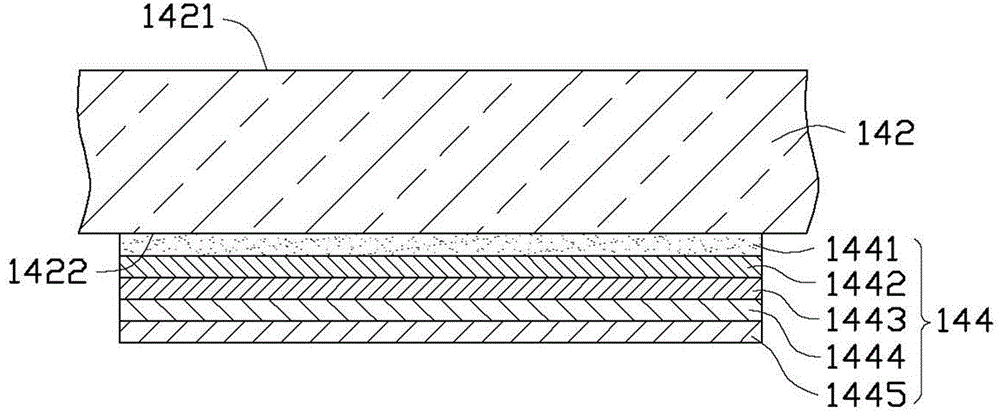

[0020] see figure 1 , The touch panel 10 according to the preferred embodiment of the present invention includes a display panel 12 and a protective cover 14 covering the display panel 12 . The protective cover 14 includes a substrate 142 , a sensing layer 144 and at least one wire 146 . The substrate 142 includes a touch surface 1421 opposite to the display panel 12 and an assembly surface 1422 opposite to the touch surface. The assembly surface 1422 includes a sensing area 1423 and a wiring area 1424 surrounding the sensing area. . The wiring area 1424 is a curved surface. The sensing layer 144 is formed in the sensing region 1423 for sensing a touch action applied on the touch surface 1421 . The at least one wire 146 is formed in the wiring area 1424 and is electrically connected with the sensing layer 144 .

[0021] That is to say, the protective cover 14 of the present invention directly arranges the wiring area 1424 on the curved surface instead of avoiding the curve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com