Edge-light backlight and liquid crystal display provided with same

A backlight and side-light technology, which is applied in the field of flat panel display, can solve the problems of increasing the manufacturing cost of the backlight, and achieve the effect of simplifying the manufacturing process and uniformly emitting light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below with reference to the drawings.

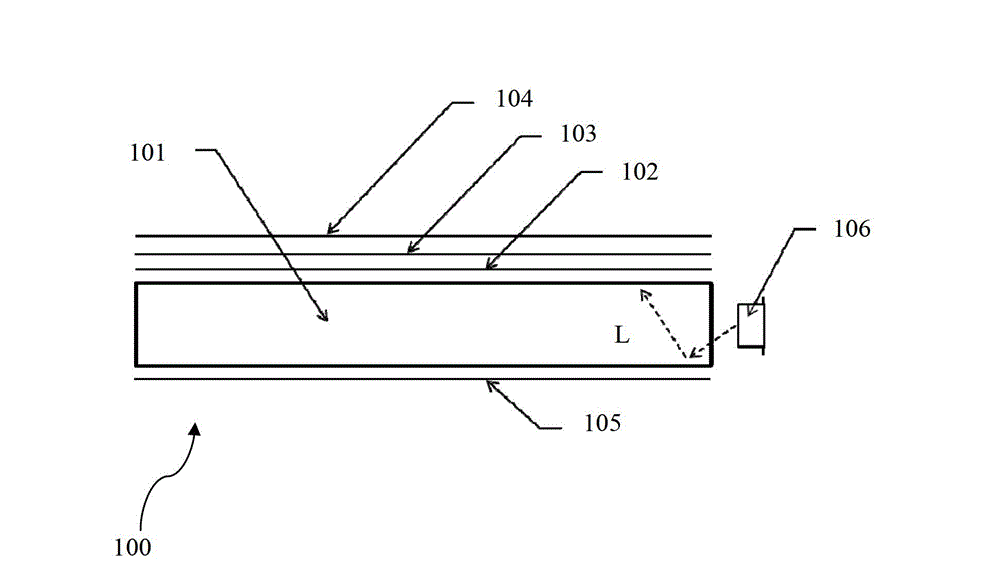

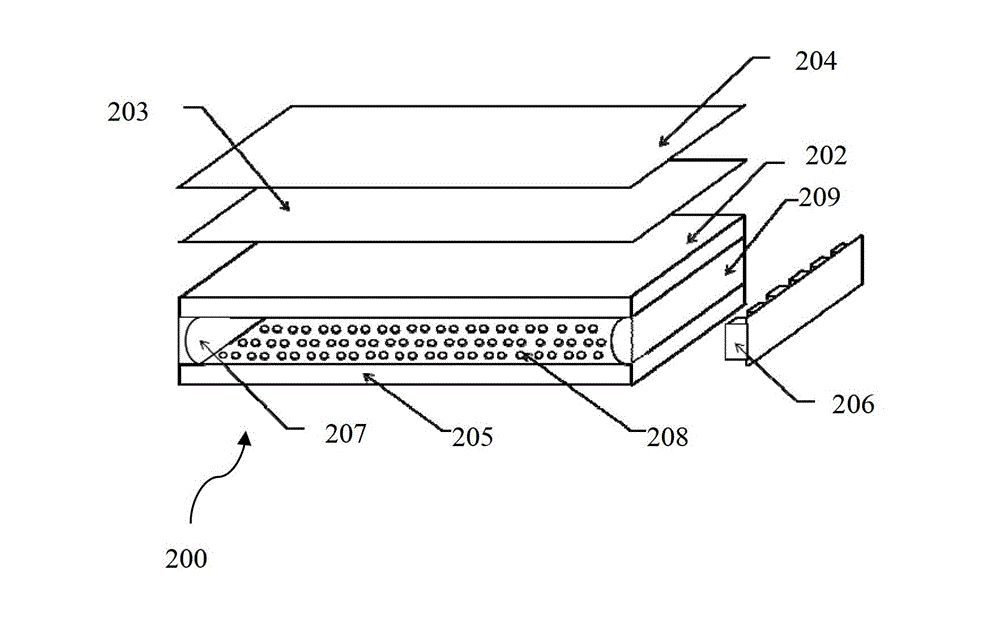

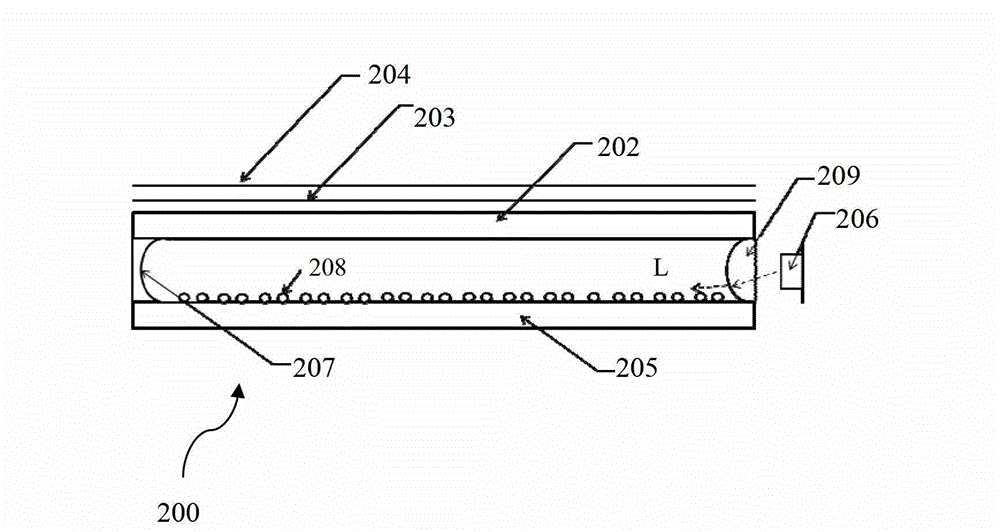

[0028] Figure 2-4 The edge-lit backlight 200 according to the present invention is shown.

[0029] The backlight source 200 includes a back plate 210 (only in Figure 4 Shown in).

[0030] The back plate 210 is provided with a reflective sheet 205 for reflecting light. In the drawing, the reflection sheet 205 is located at the lower part. The reflective sheet 205 is provided with reflective particles 208, and the reflective sheet 205 reflects light with the assistance of the reflective particles 208.

[0031] The reflective particle 208 in the present invention is a miniature optical reflective material, and its function is to change the refraction angle of light by selecting different materials to meet design requirements. The reflective sheet 205 itself can reflect light, and the role of the reflective particles 208 is to perform secondary processing on the light to meet the design r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com