A backwashing and decontamination type sub-catchment

A technology of water separator and water collector, which is applied in the field of machinery, can solve the problems of large floor area and double water resistance, and achieve the effects of small filtering resistance, good fluidity, and reducing the floor area of the machine room

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

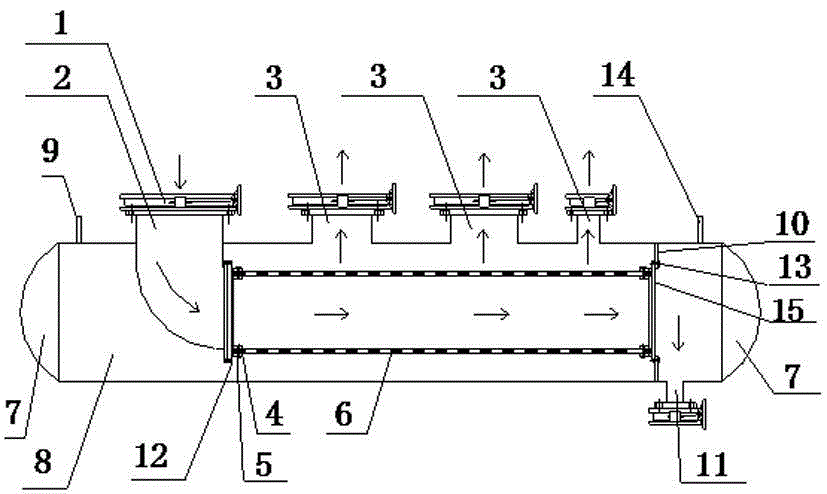

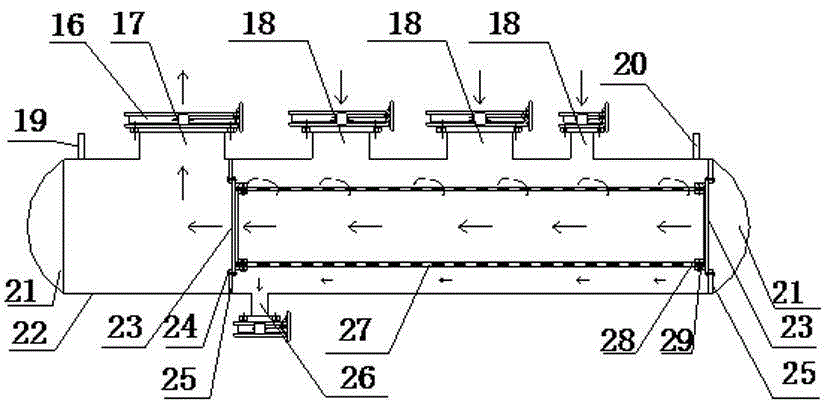

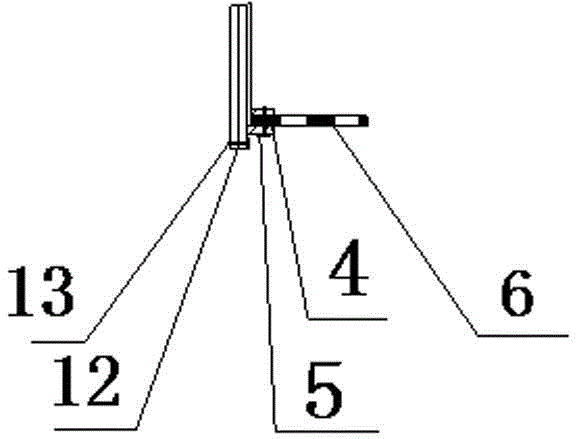

[0029] The sub-water collector device of the present invention comprises a cylindrical body, a head, a connecting pipe, a filter screen and accessories (half inner and outer hoops, outer hoops, flange covers, water retaining plates, nuts, temperature and pressure gauge connection gauges). For a heating user, the heat medium is 95°C hot water, the water volume is 20,000kg / h, and the hot water flow rate is 0.1m / s. 20R seamless steel pipe is used as the material of the cylinder and the head, all the connecting pipes are seamless steel pipes, the filter screen is made of stainless steel screen, the nut is M16, and the bolt is M16×55. The diameter of the water inlet and outlet pipes is 100mm, the branch pipe is 70mm, the diameter of the cylinder is 325mm, the height of the head is h=106mm, the length of the manifold is L=1922mm, the diameter of the drainage pipe is 50mm, and the wall thickness of the head and the cylinder is 6mm.

[0030] In the normal operation state of the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com