Automatic crust breakage biogas fermentation tank

A biogas fermentation and automatic shell breaking technology, which is applied in the fields of gas production bioreactors, biochemical instruments, biological sludge treatment, etc., can solve the problems of limited scum area and high water pressure, and achieve simple structure, reliable operation, and material selection. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

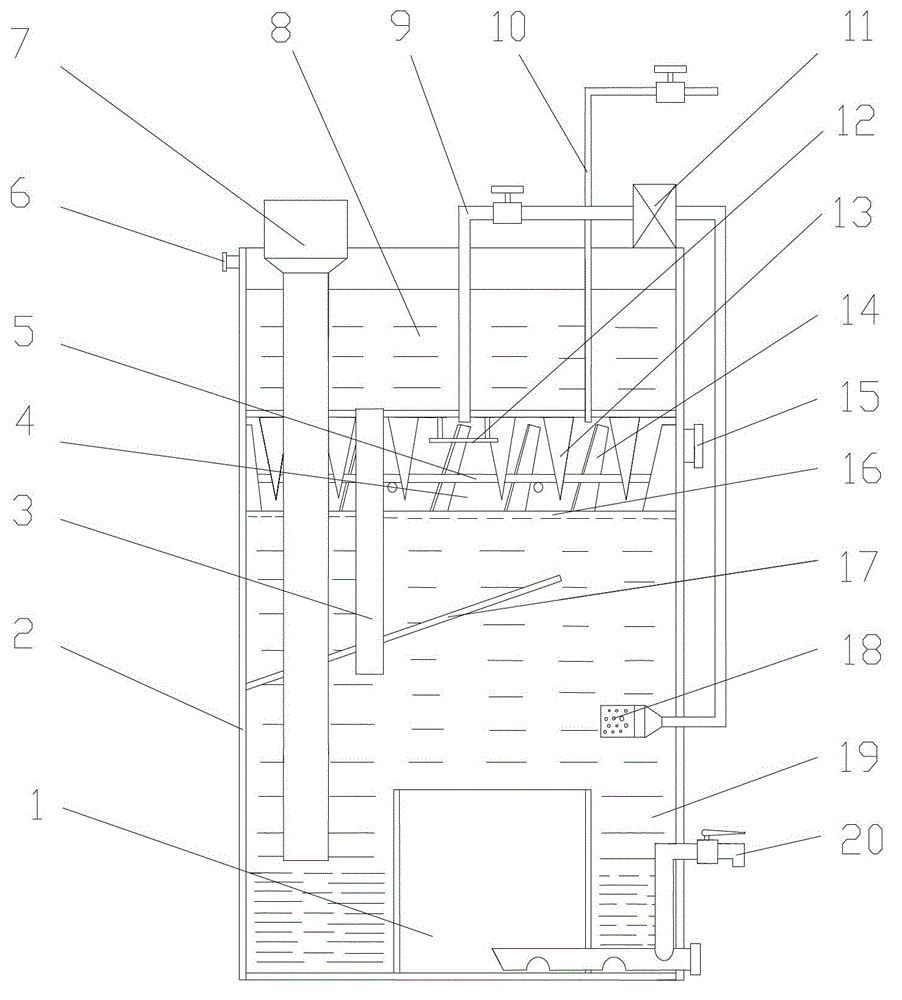

[0018] The present invention will be further described below in conjunction with the drawings.

[0019] The tank body 2 of the automatic shell-breaking biogas fermentation tank of the present invention is sequentially provided with a water pressure room 8, a gas storage chamber 4, and a fermentation room 19 from top to bottom. The top of the water pressure room 8 is provided with an overflow port 6, and the water pressure room 8 and The fermentation room 19 is connected by a connecting pipe 3, the gas storage chamber 4 is connected with a gas pipe 10 leading to the outside of the tank body, a scum outlet 15 is provided on the side of the gas storage chamber 4, and a secondary tank is connected to the fermentation room 19 The feed pipe 7 inserted into the outside of the body, the gas storage chamber 4 is equipped with a well-shaped frame 5 and several shell-breaking cones 13. The bottom end of the shell-breaking cone 13 is pointed and faces the fermentation room 19. The top end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com