Novel dry-mixed plastering mortar

A plastering mortar and dry-mixing technology, which is applied in the field of building materials, can solve problems such as occupying agricultural land, casualties, air and water and soil pollution, and achieve the effects of avoiding damage, excellent performance, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

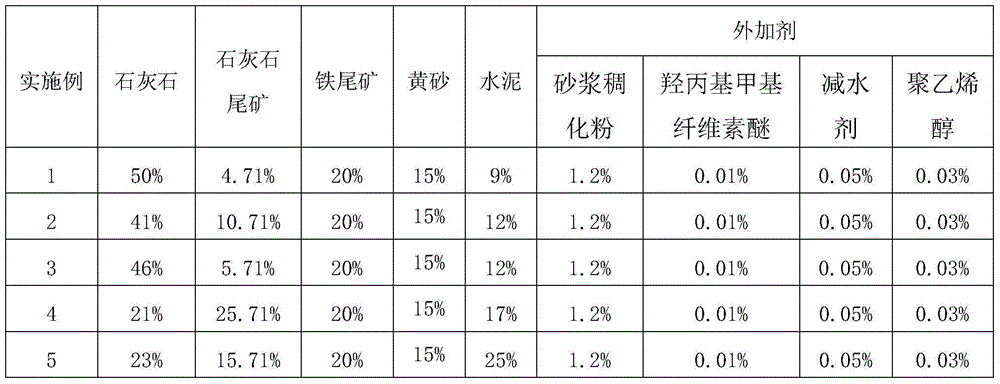

[0019] Table 1

[0020]

[0021] Performance Testing

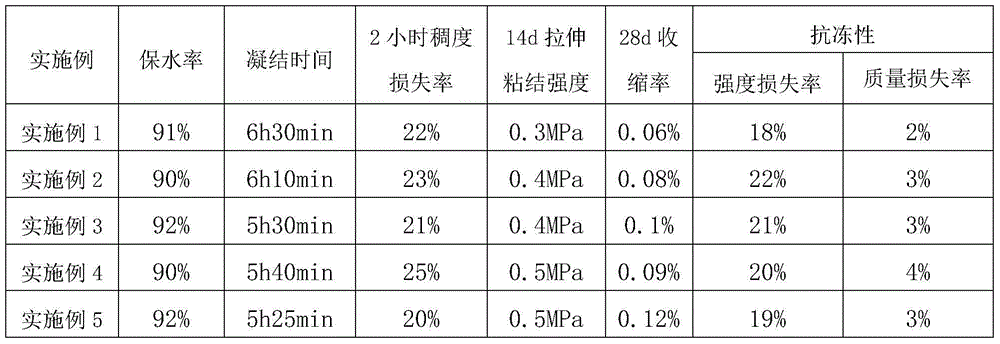

[0022] Test the water retention, setting time, 14d tensile bond strength, 28d shrinkage and frost resistance of the mortar of the present invention respectively according to the relevant regulations of JGJ / T70, according to Appendix A "Consistency Loss Rate Test Method" in GB-T25181-2010 The relevant regulations test the 2-hour consistency loss rate of the mortar of the present invention, and the test results are shown in Table 2.

[0023] Table 2

[0024]

[0025] According to JGJ / T70 standard test 28d compressive strength, the test results are as follows:

Embodiment 1

[0026] Embodiment 1 is the strength grade of M5, and test result is 5.3MPa;

Embodiment 2

[0027] Embodiment 2 is the strength grade of M10, and test result is 11MPa;

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com