Downhole treatment and reuse device and method for mine water

A technology for water wells and mines, applied in the field of underground water treatment and reuse devices in mines, can solve the problems of backward technology, high maintenance costs, waste of resources, etc., and achieve the effects of reducing environmental pollution, high safety, and comprehensiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

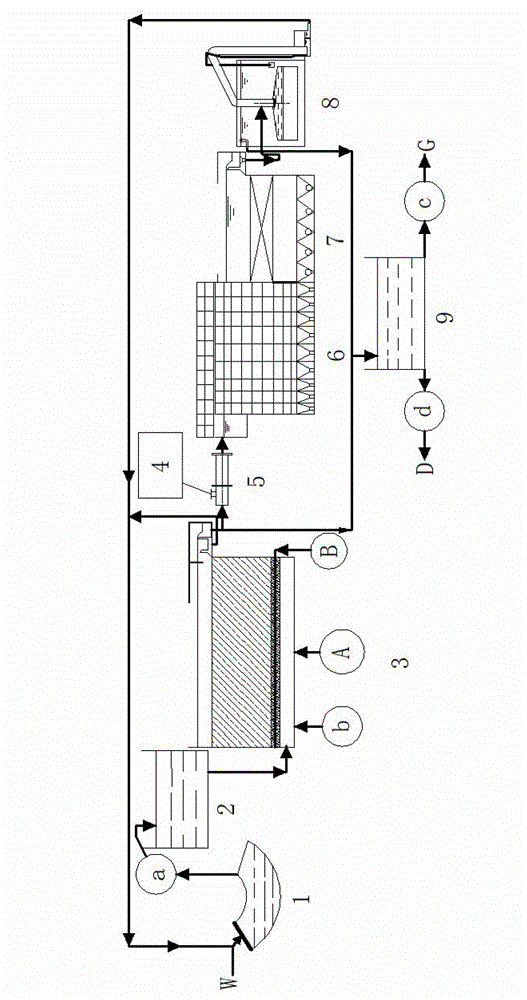

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

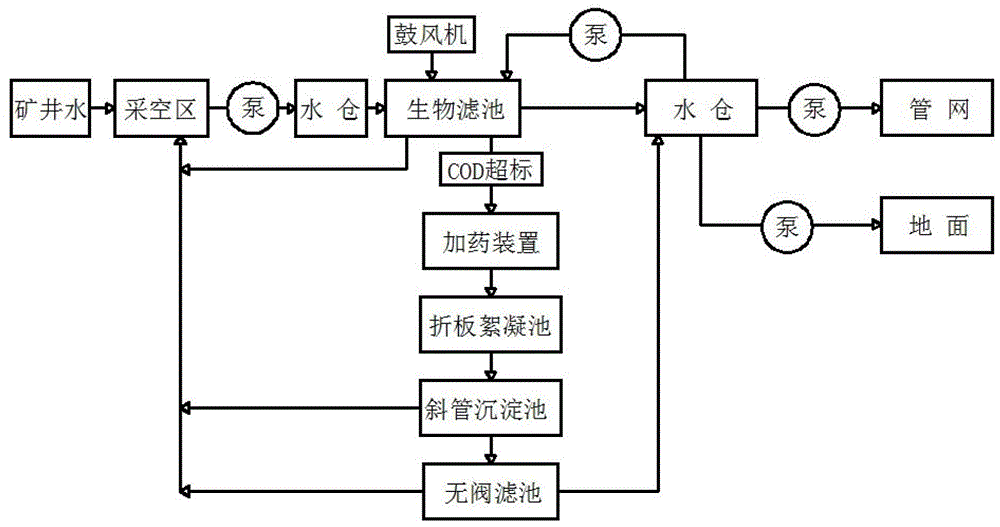

[0025] Aiming at the current status of mine water treatment, that is, ground treatment is the main method, it occupies a large area, pollutes the environment, and is transported over long distances, while the idle goaf and abandoned roadways cause waste of resources. The device is arranged underground, and includes a natural self-purification mechanism, a primary filter mechanism, a COD detection mechanism, a drug-adding flocculation mechanism, a secondary filter mechanism, and a water supply mechanism. The COD detection mechanism detects the water quality of the filtrate in the primary filter mechanism The water inlet of the natural self-cleaning mechanism is the goaf entrance provided with the grid, and the water outlet is connected with the water inlet of the primary filter mechanism; the sewage outlet of the primary filter mechanism is connected with the back discha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com