Hanging cage walls and hanging cages

A technology of hanging cages and surrounding walls, which is applied to elevators, transportation and packaging in buildings, etc. It can solve the problems of short service life of surrounding walls, achieve the effects of improving service life, firm design and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

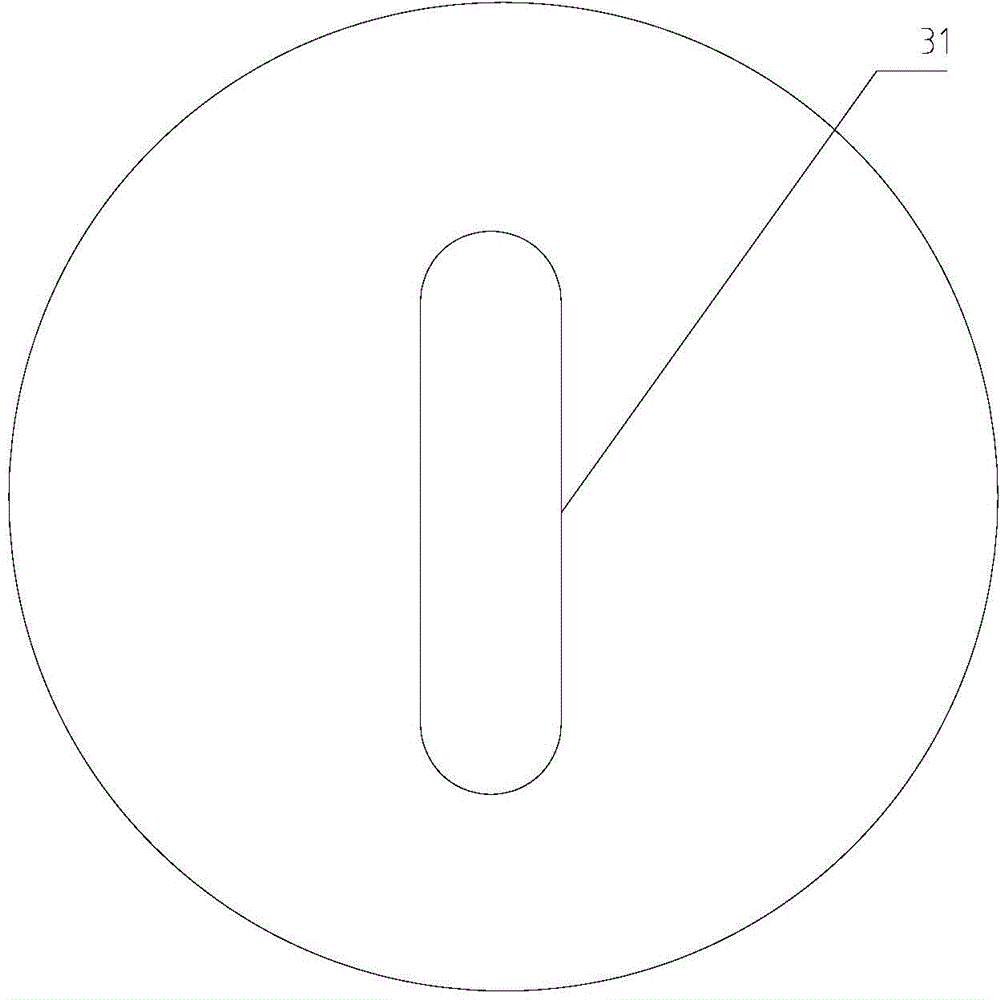

[0022] Below in conjunction with accompanying drawing, the hanging cage surrounding wall of the present invention will be further described. Such as figure 1 , image 3 As shown, the surrounding wall of the hanging cage, the surrounding wall includes the anti-skid plate 1 welded on the lower part of the side wall of the hanging cage 5, the closing plate 2 arranged in the middle part of the side wall of the hanging cage 5, and the cross-sectional shape of the through hole 31 is rectangular and bolted The punching plate 3 fixed on the upper part of the side wall of the hanging cage 5, the height of the surrounding wall anti-skid plate 1 accounts for 1 / 3 to 1 / 2 of the total height of the hanging cage 5 is arranged on the lower part of the side wall of the hanging cage 5, and the surrounding wall The height of the closing plate 2 accounts for 1 / 4-1 / 3 of the height of the cage 5 and is arranged in the middle of the cage 5. The rest of the surrounding wall is a punching plate 3. Th...

Embodiment 2

[0027] The difference between this embodiment and Embodiment 1 is that, as figure 1 , figure 2As shown, one end of the closing plate 2 on one side of the surrounding wall close to the guide rail of the cage is connected to the cage 5 in rotation and the other end is fixed on the cage 5 through a locking device 4. One end of the closing plate 2 can be hinged, The connecting means such as pin shafts are rotatably connected on the cage 5, and two locking devices 4 are arranged between the cage 5 and the closing plate 2, and the locking devices 4 include a latch and a setting In the slot on the hanging cage 5, the locking device 4 is opened during the operation, and the other end of the closing plate 2 is arranged on the hanging cage 5 through a rotating connection. The opening operation of the closing plate 2 is very convenient, and the closing plate 2 is closed after the maintenance is completed The assembly operation is also very convenient. It only needs to lock the locking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com