Triangular tray for vulcanized rubber tube

A triangular, vulcanized rubber technology, applied in the field of auto parts manufacturing, can solve problems such as waste and insufficient use of space, and achieve the effect of increasing the number of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below by example the present invention is further specifically described, but the present invention is by no means limited to this example.

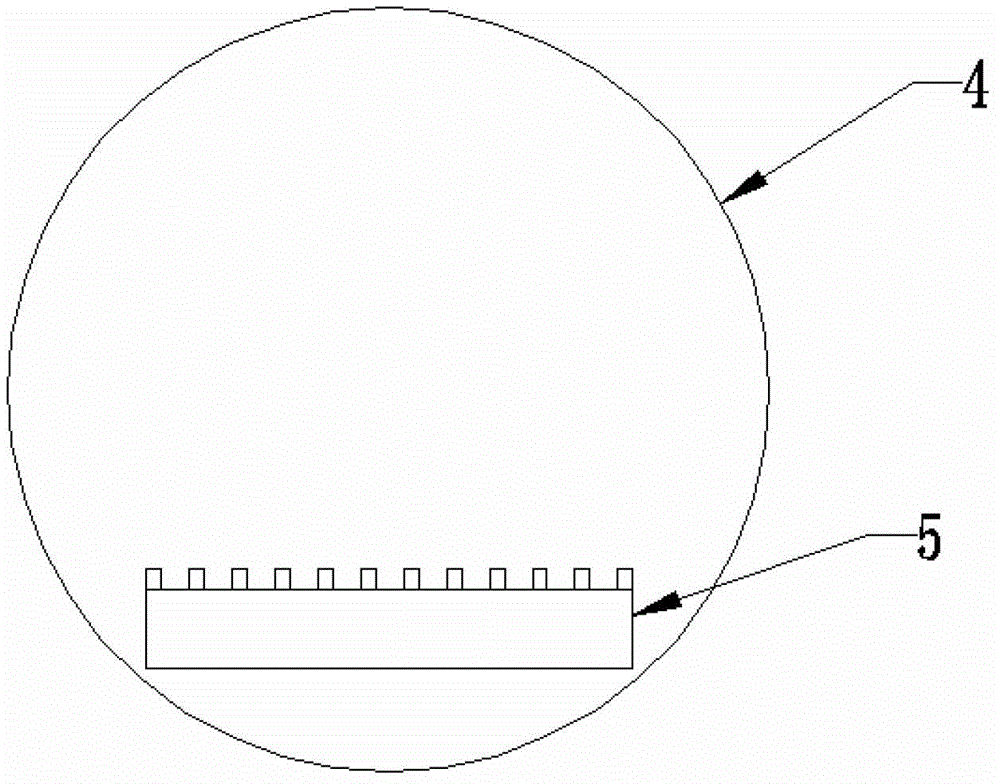

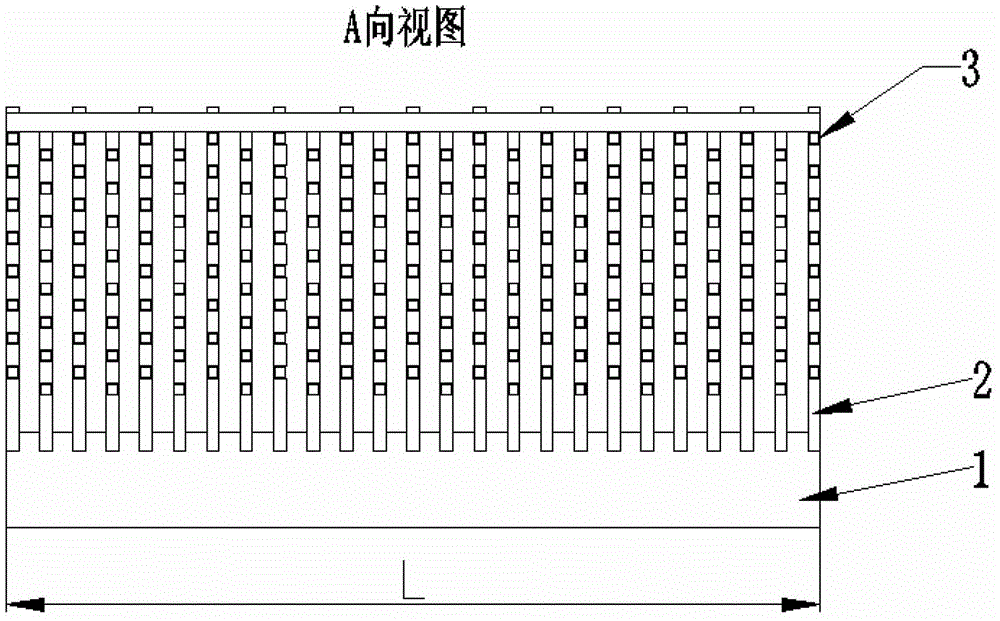

[0018] Such as Figure 1~4 Shown: a triangular tray for vulcanization of automobile rubber hose, which is composed of a base 1, a support beam 2, and a square tube 3. The overall cross-section is triangular, and the two hypotenuses of the triangle are support beams 2, and multiple square tubes are arranged on the support beam , the aperture of the square tube 3 is greater than the aperture of the vulcanized mandrel square tube. A plurality of triangular support beams are welded on the base, the distance between the support beams is greater than or equal to twice the width of the support beams, and the square tubes between two adjacent support frames should be misplaced. The direction of the mouth of the square tube on the support beam is toward the obliquely upward, and the depth of the square tube is the height of the square tub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com