Powder material homogenization device

A homogenizing device and technology for powdery materials, which are applied in clay preparation devices, cement mixing devices, chemical instruments and methods, etc., can solve the problems of poor mixing and homogenizing effect, single structure of mixing and homogenizing equipment, etc. Homogenizing effect, ensuring production quality and process stability, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

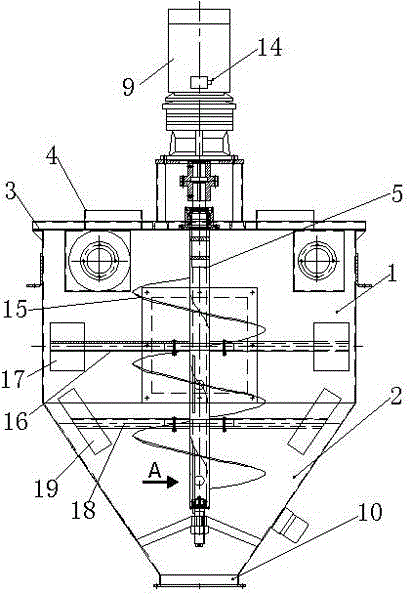

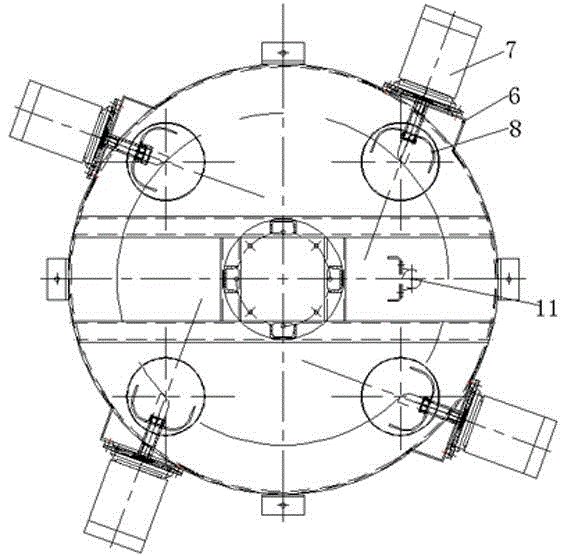

[0021] refer to Figure 1 to Figure 5 , the present invention relates to a powder material homogenization device, comprising an upper drum 1 and a lower conical drum 2 connected with the lower end of the upper drum 1, the upper end of the upper drum 1 is connected with a cover plate 3, the The upper end surface of the cover plate 3 is evenly distributed with at least two material inlets 4 along the circumferential direction, and a material stirring mechanism is respectively arranged on the peripheral wall of the upper drum 1 corresponding to each material inlet 4, and the upper drum and the An agitator is longitudinally arranged in the inner cavity of the lower cone barrel.

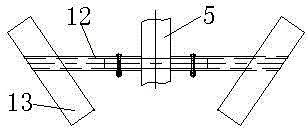

[0022] The above-mentioned agitator includes a vertically arranged agitating shaft 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com