Twisting shaft synchronizing device of bending machine

A technology of synchronous device and bending machine, which is applied in the field of bending machines, can solve problems such as low balance performance, cumbersome parts processing, and complicated assembly and adjustment, and achieve the effects of simple assembly and adjustment, improved product quality, and easy processing of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be described in further detail below in conjunction with the accompanying drawings.

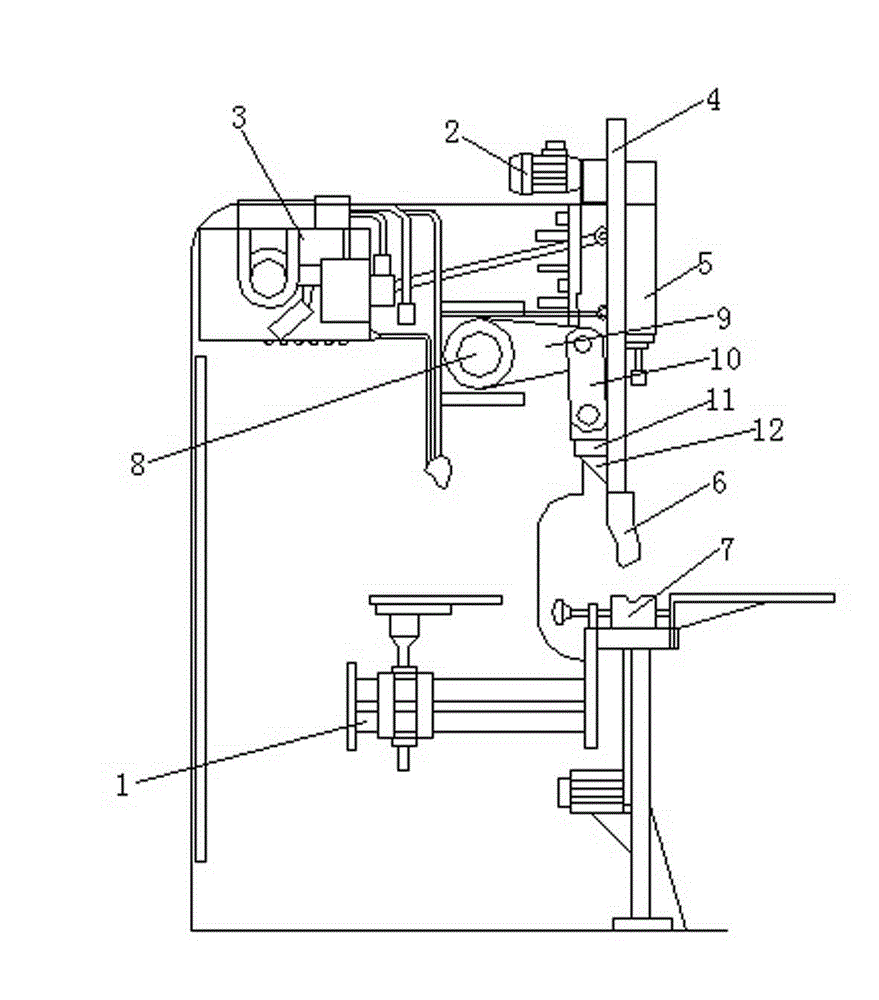

[0008] Such as figure 1 As shown, the torsion axis synchronization device of the bending machine includes the rear gauge device 1, the oil tank, the fine-tuning motor 2, the oil cylinder, the valve group 3, the slider 4, the piston rod 5, the electrical system, the workbench, the upper module 6, and the lower module 7 and a torsion shaft synchronizing device, the torsion shaft synchronizing device includes a synchronizing torsion shaft 8, a swing arm 9 connected to both ends of the synchronizing torsion shaft 8 and a connecting rod 10 connected to the swing arm 9, the swing arm One end of 9 is movably connected with the synchronous torsion shaft 8, and the other end of the swing arm 9 is movably connected with the connecting rod 10. The bottom end of the connecting rod 10 is provided with a swing arm pier 11, and the bottom of the swing arm pier 11 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com