Automatic microscope glass slide cleaning method and automatic microscope glass slide cleaning device

An automatic cleaning and glass slide technology, applied in the field of experimental instruments, can solve the problems of exposure to harmful substances, low work efficiency, and potential safety hazards, and achieve the effects of reducing contact, reducing work risks, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] This embodiment discloses a method for automatic cleaning of microscope slides, comprising the following steps:

[0024] 1) Place the glass slide at the beginning of the conveyor belt, the upper surface of the glass slide is stained with cedar oil;

[0025] 2) The conveyor belt transports the glass slide to the first position and stops; the upper surface of the glass slide is covered with lens cleaning paper;

[0026] 3) The conveyor belt transports the glass slide to the second position and stops; add ether to the lens cleaning paper covering the upper surface of the glass slide;

[0027] 4) When the conveyor belt transports the glass slide to the third position, it can stop or not, and remove the lens-cleaning paper strip covering the upper surface of the glass slide;

[0028] 5) The conveyor belt continues to transport the slides, which fall into the collection basket located below the end of the conveyor belt.

[0029] It is worth noting that, in steps 2 to 4 in t...

Embodiment 2

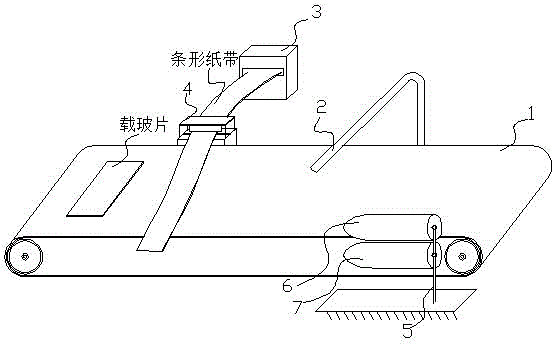

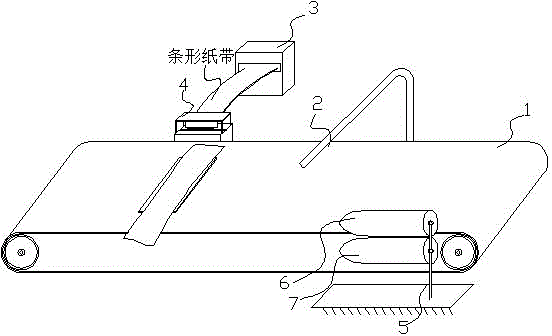

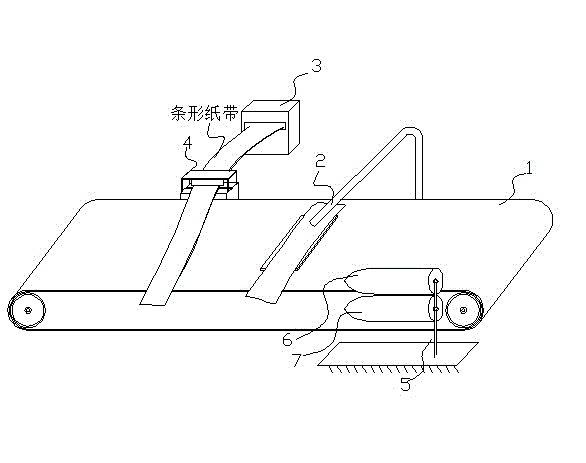

[0032] This embodiment provides an automatic cleaning device for microscope slides that implements the method described in Example 1, including a conveyor belt 1 that supports and transmits microscope slides, a conveyor belt stepping motor, a paper delivery system, a paper removal system, and cleaning droplets Add device.

[0033] The conveyor belt 1 is driven by a stepping motor. In this embodiment, the conveyor belt 1 is an ordinary industrial conveyor belt, which is used to transport the slides from one end (starting end) to the other end (end). In this embodiment, the width of the conveyor belt 1 is greater than the length of the slide glass. From the beginning to the end of the conveyor belt 1, the paper delivery system, the cleaning liquid dripping device and the paper taking system are arranged in sequence. The paper delivery system and the paper pickup system are installed on both sides of the conveyor belt 1, but not on the same side.

[0034] The paper delivery sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com