Zipper and manufacturing method thereof

A manufacturing method and zipper technology, applied in the direction of sliding fastener components, applications, fasteners, etc., can solve the problems of zipper unevenness, wrinkling, affecting the appearance and quality of clothing, and achieve the effect of avoiding fabric wrinkling and increasing length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

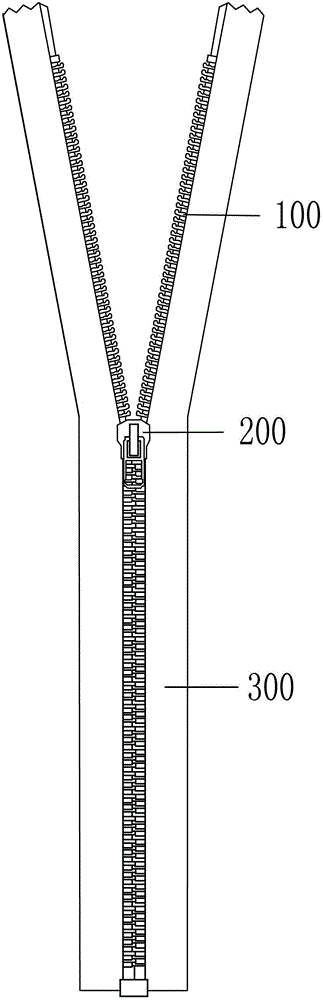

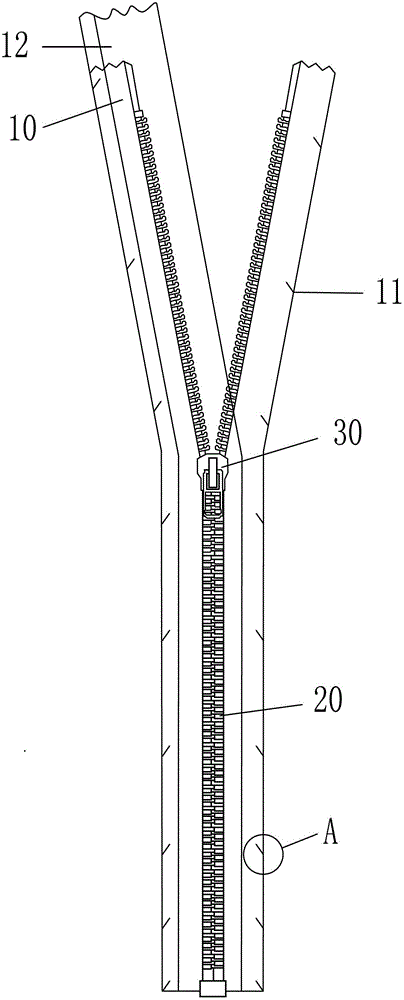

[0034] Please refer to Figure 2 to Figure 7 The embodiment of the present invention provides a zipper, including a zipper tape 10 , zipper teeth 20 fixed on the inner edge of the zipper tape 10 , and a zipper puller 30 for engaging and separating the zipper teeth 20 .

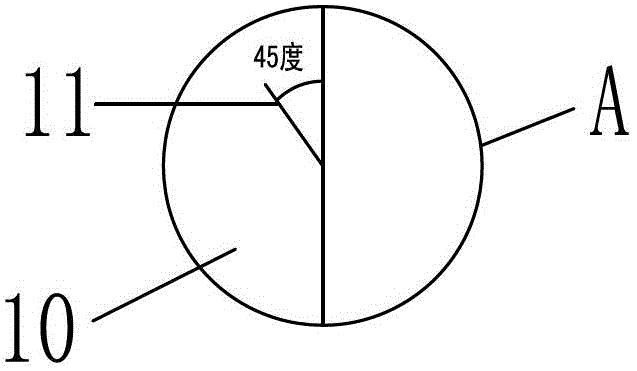

[0035] The zipper also includes: on the outer edge of the zipper tape 10 uniformly provided with a predetermined depth and at intervals of a predetermined distance, beveled slits 11, the beveled slits 11 and the corresponding axis of the zipper tape 10 have a predetermined angle, and The outer edge of the zipper tape 10 is wrapped and sewn with a lining strip 12 , the lining strip 12 is aligned with the two ends of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com