Method for preparing 1,3,5-trioxane

一种三氧杂环己烷、装备有的技术,应用在分离方法、化学仪器和方法、医药配方等方向,能够解决工艺复杂、消耗过多能量等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

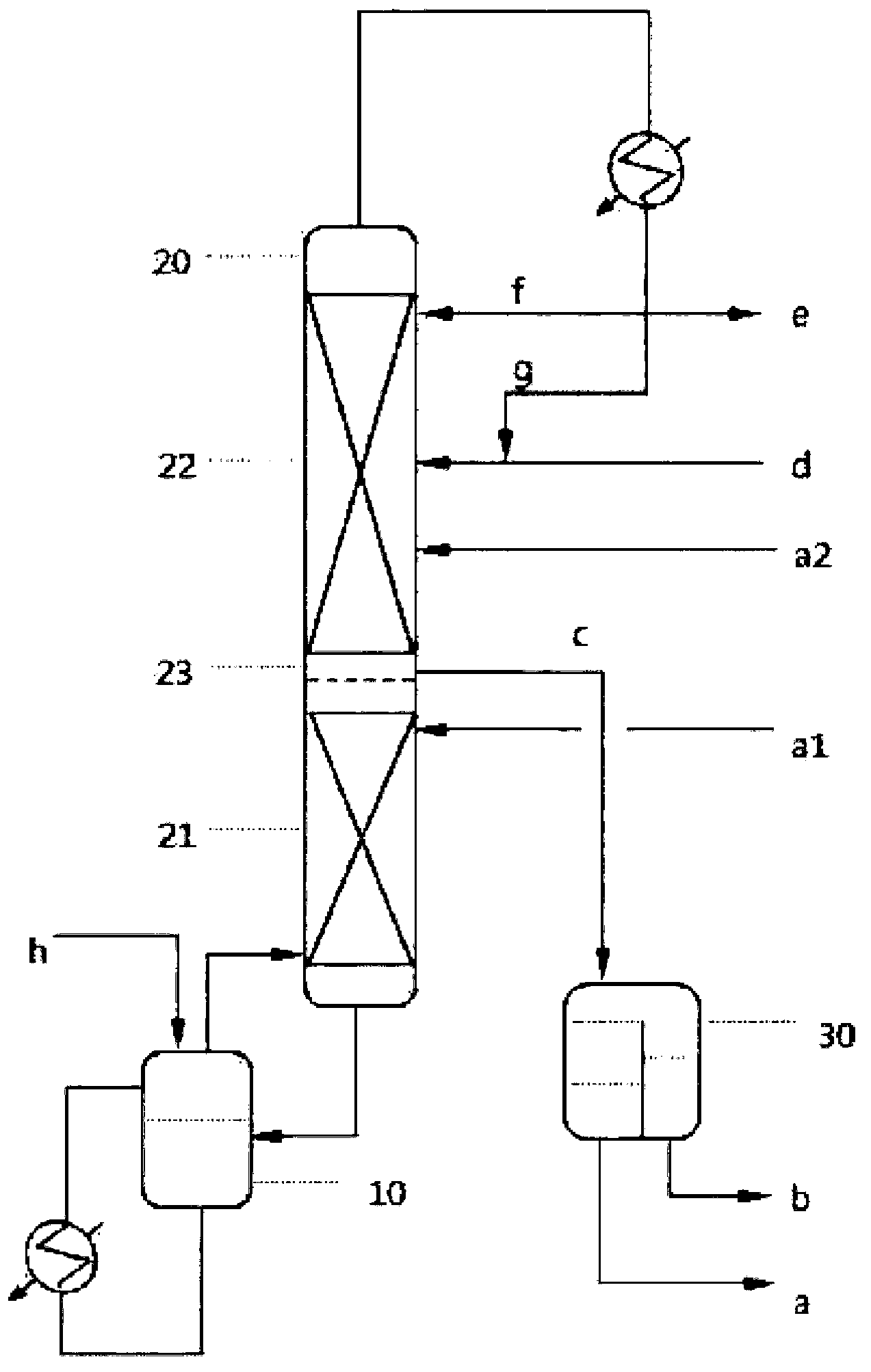

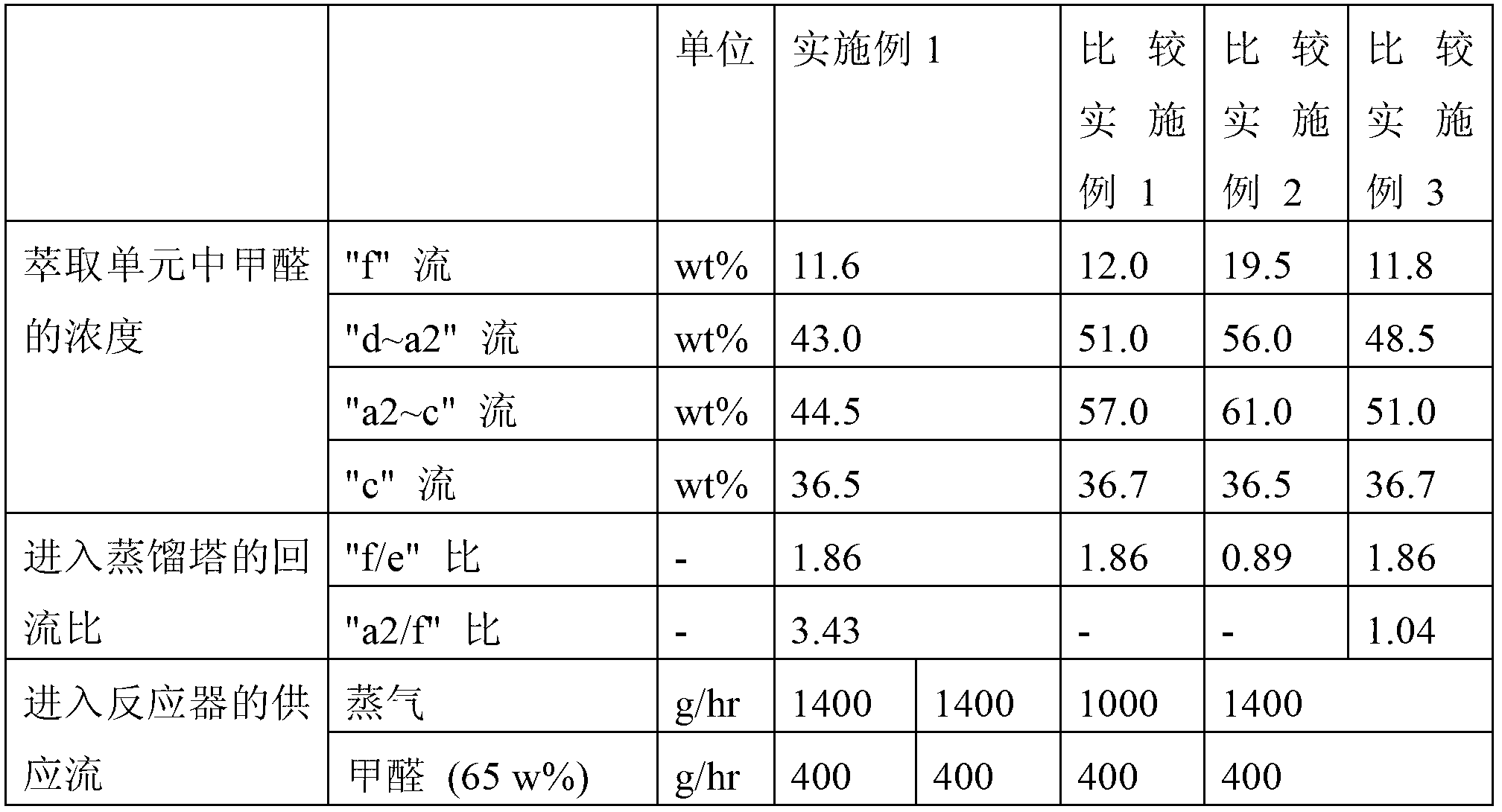

[0043] use figure 1 The reactive distillation column shown produces 1,3,5-trioxane. The reactive distillation tower includes a distillation tower 20, a reactor 10 (5 L in volume, equipped with a heating unit) and a decanter (1.5 L in volume), and the distillation tower 20 is equipped with a distillation unit 21 (30 mm in diameter, 15 stages, bubble-cap tray ), extraction unit 22 (diameter 50mm, 20 stages, bubble cap tray) and side draw unit 23 (1 stage, chimney tray) arranged between distillation unit 21 and extraction unit 22.

[0044] An aqueous formaldehyde solution having a concentration of 65.0 wt% was supplied to the reactor 10 at a flow rate of 400 g / hr, and the concentration of sulfuric acid in the reaction solution was set at 2.0 wt%. The 1,3,5-trioxane-containing vapor generated by steam heating at 1400 g / hr was supplied to the distillation unit 21 of the distillation column 20 .

[0045] The 1,3,5-trioxane-containing vapor is fed to the extraction unit 22, while b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com