Double-shaft tracking support

A dual-axis tracking and bracket technology, applied in the support structure of photovoltaic modules, photovoltaic modules, mobile/directional solar collectors, etc., can solve the problems that hinder the commercial development of tracking technology, increase road and foundation requirements, and difficult installation and maintenance. increase and other problems, to achieve the effect of high market promotion value, low production cost, and elimination of huge eccentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

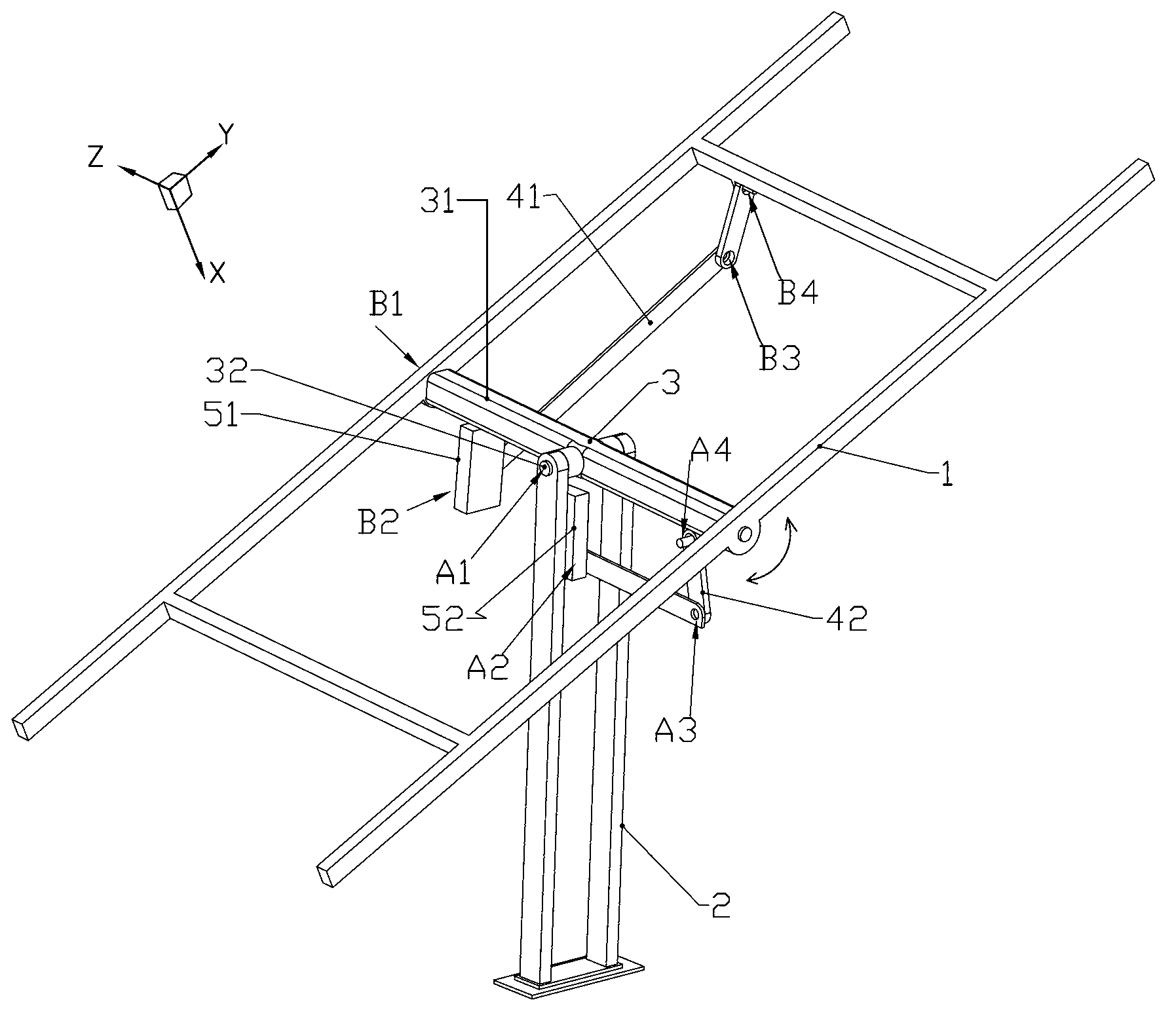

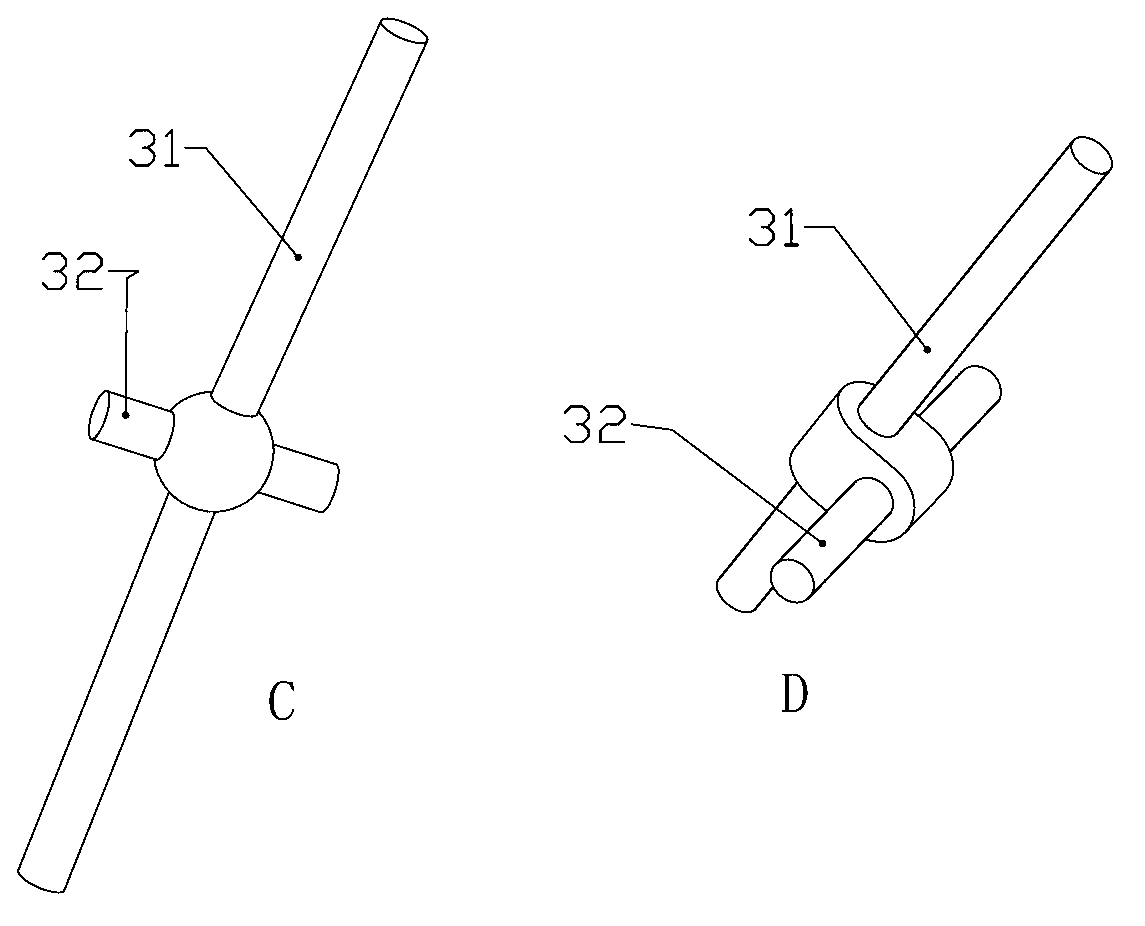

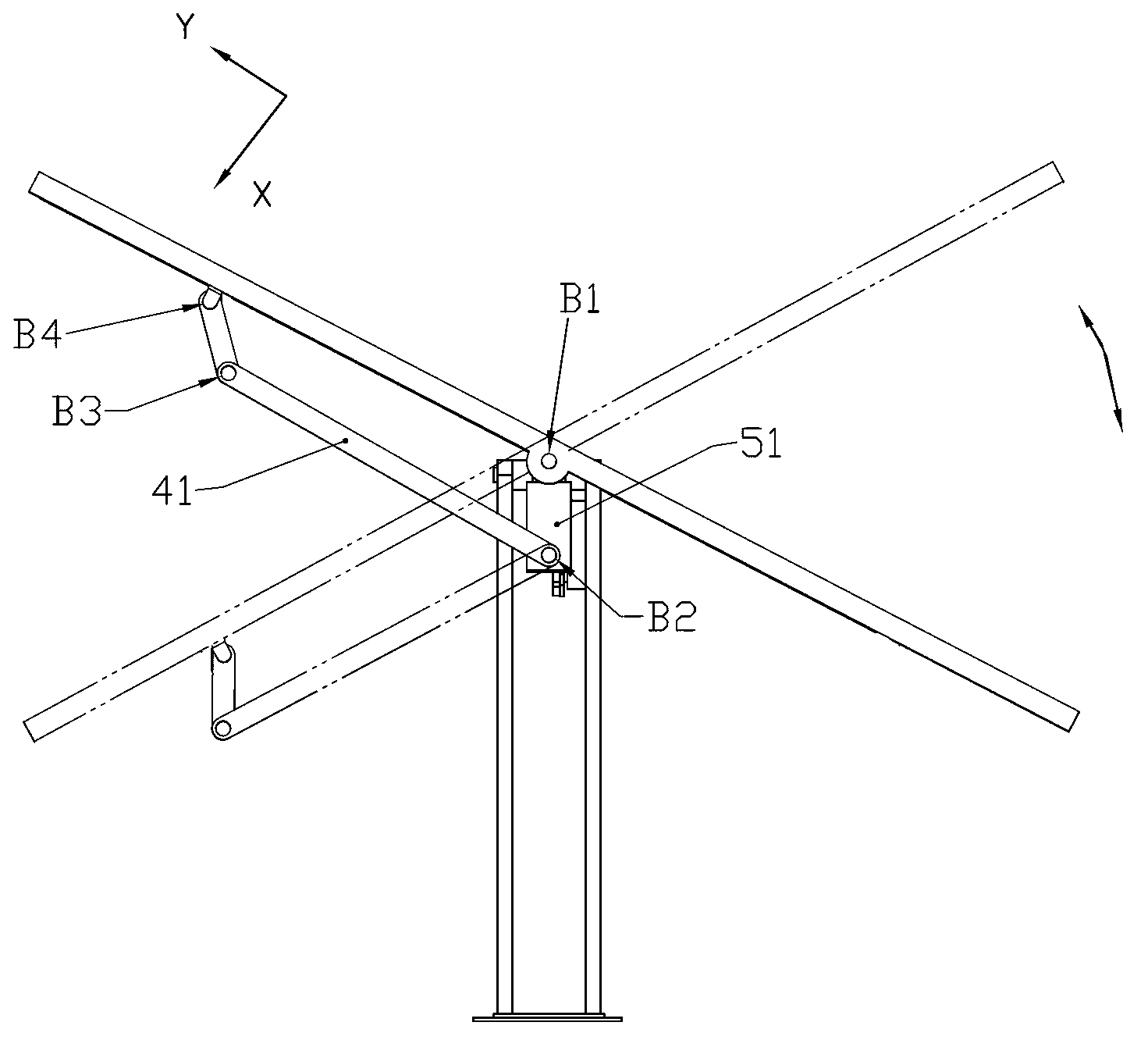

[0040] like Figure 1~3As shown, the dual-axis tracking bracket includes a bracket 1, a column 2, a central pivot shaft 3, a rotation angle adjustment device and an elevation angle adjustment device. For ease of description, first define the direction parallel to the plane where bracket 1 is located and along the solar daily orbit as the Y direction (rotation angle), and define the direction parallel to the plane where bracket 1 is located and along the solar annual orbit as the Z direction ( elevation angle), then the direction perpendicular to the YZ plane and facing the back of the bracket 1 is the X direction.

[0041] see figure 1 , in one embodiment, the bracket 1 may be a steel pipe welded or bolted frame structure for fixing solar modules. Obviously, the above-mentioned frame structure is not limited thereto, but can be made of any other suitable materials, such as aluminum alloy profiles and the like. like figure 1 As shown, in one embodiment, the upright column 2...

Embodiment 2

[0055] like Figure 4 As shown, the difference from Embodiment 1 is that the first transmission part of the angle adjustment device of the tracking bracket is composed of a first moment arm lever 71 and a first transmission rope 711 and a second transmission rope 712 of equal length. One end of a transmission rope 711 is connected on the bracket 1, and the other end is connected with the end of the first moment arm lever 71; the middle of the first moment arm lever 71 is fixedly connected with the output shaft of the first driving part 51, and the second transmission One end of the rope 712 is connected on the bracket 1, and the other end is connected with the other end of the first moment arm bar 71, and tensioned; as Figure 4 As shown, the first moment lever 71, the bracket 1, the first transmission rope 711 and the second transmission rope 712 jointly form a parallelogram linkage mechanism, and the linkage mechanism is driven by the first driving part 51. Get some exercis...

Embodiment 3

[0059] like Figure 5 As shown, the difference from Embodiment 1 or 2 is that the second transmission part of the elevation angle adjustment device of the tracking bracket is an elevation angle adjustment rod 61, one end of which is fixedly connected to the corner pivot shaft 31 of the central pivot shaft 3 , the other end is fixedly connected to the body of the first driving part 51, on the elevation angle adjustment rod 61, an array of positioning holes 62 is set according to the change law of the sun's annual operating altitude angle, and on the column 2, two belts are fixed up and down in layers The positioning plate with the positioning hole forms the positioning structure 64, the elevation angle adjustment rod 61 passes through it, and a T-shaped positioning pin 63 passes through the hole of the positioning structure 64 and the elevation angle adjustment rod 61 from top to bottom, and adjusts the elevation angle. The rod 61 is locked to achieve the purpose of locking the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com